Electric vehicle range extender grid rotor motor

A technology for electric vehicles and rotor motors, applied in the field of electric vehicles, can solve the problems of strong heat dissipation, large size and weight of generators, and achieve the effects of easy heat dissipation, large magnetic conduction area, and high motor power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

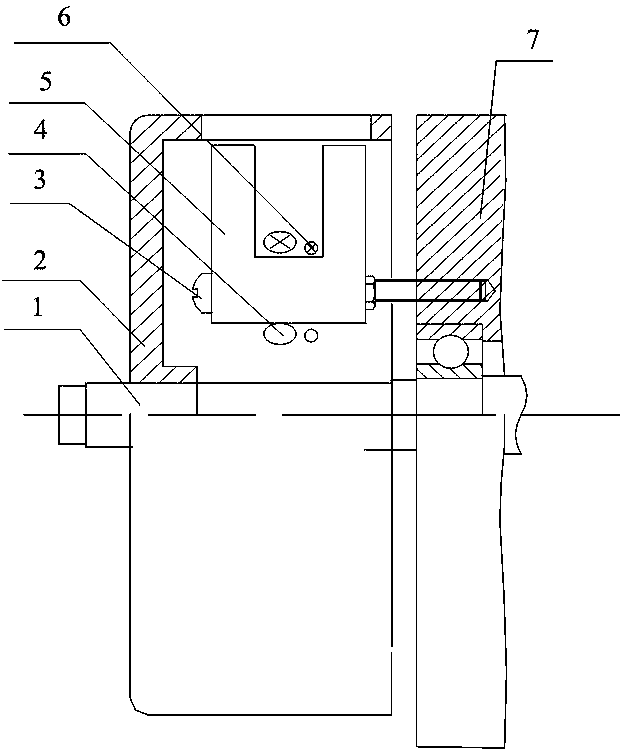

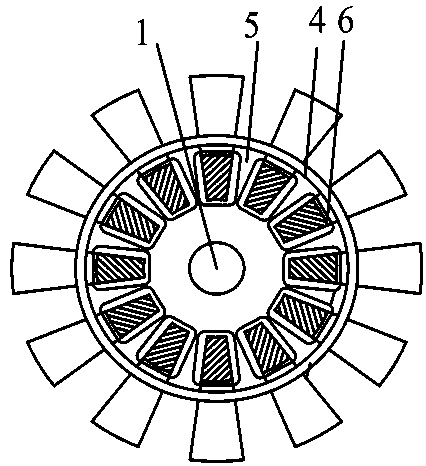

[0022] figure 1 It is a longitudinal sectional view of a grid-shaped rotor motor for an electric vehicle range extender according to the technology of the present invention. Among them, 1 crankshaft, 2 housing, 3 fixing bolts, 4 field winding, 5 stator core, 6 armature winding, 7 range extender housing.

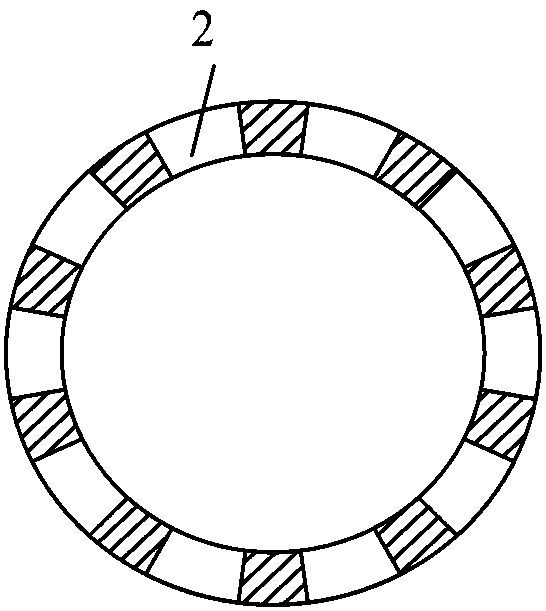

[0023] The electric vehicle range extender grid-shaped rotor motor is characterized in that: the casing is used as the outer rotor of the motor, and the casing is fixed at the end of the crankshaft; 10 rectangular holes are evenly distributed on the circumferential surface of the casing, and there are 10 rectangular holes between any two rectangular holes. Magnetic grid core.

[0024] The stator core fixed on the range extender housing is composed of 12 evenly distributed "匚" shaped sub-stator cores. Both sides of the sub-stator core are radially protruding stator poles, and the sides of the stator poles are fan-shaped; The distance between two stator poles on a sub-stator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com