Full winding slab continuous casting mold electromagnetic stirring device and slab continuous casting mold

A slab continuous casting and electromagnetic stirring technology is applied in the field of electromagnetic stirring devices and molds, which can solve the difficulty of manufacturing a cylindrical iron core, the reduction of the ratio of the cross section of the winding and the cylindrical iron core, and the small number of coil turns and magnetic conduction area. and other problems, to achieve the effect of weakening the fluctuation of the meniscus liquid level, preventing the fluctuation of the molten steel level, and improving the space utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

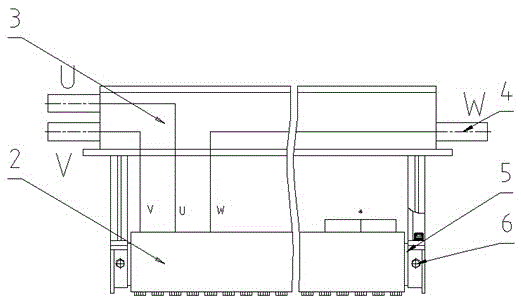

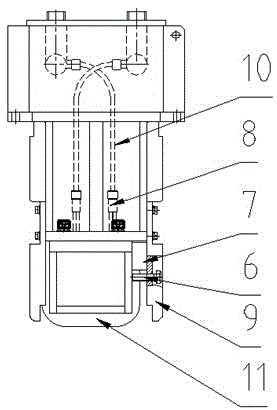

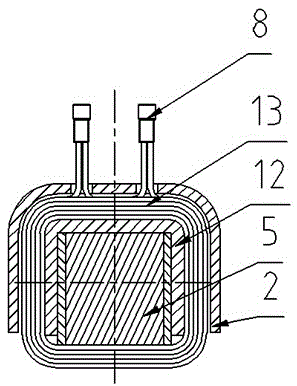

[0022] Such as Figure 1-Figure 4 As shown, the electromagnetic stirring device in one embodiment of the present invention includes a columnar iron core 5 without cogging on the working surface; the non-working surface of the columnar iron core 5 is arranged in the inner water cooling jacket 12; on the columnar iron core 5 of the inner water-cooling jacket 12; the coil 13 on the inner water-cooling jacket 12 is arranged in the outer water-cooling jacket 2; the inner water-cooling jacket 12 and the outer water-cooling jacket 2 are provided with circulating pipelines, and the circulation Each of the two ends of the pipeline communicates with a water pipe joint 8 . There is an opening on one side of the inner water-cooling jacket and the outer water-cooling jacket, and its shape is determined according to the shape of the cylindrical iron core. Grooves are provided at the same position on the bonding surfaces of the plates. After the two metal plates are bonded, the grooves on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com