Lens actuating device

A lens actuation and lens technology, applied in electromechanical devices, installation, optics, etc., can solve the problems of power consumption, energy waste, large camera module size, cost increase, etc., and achieve the effect of increasing electromagnetic thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

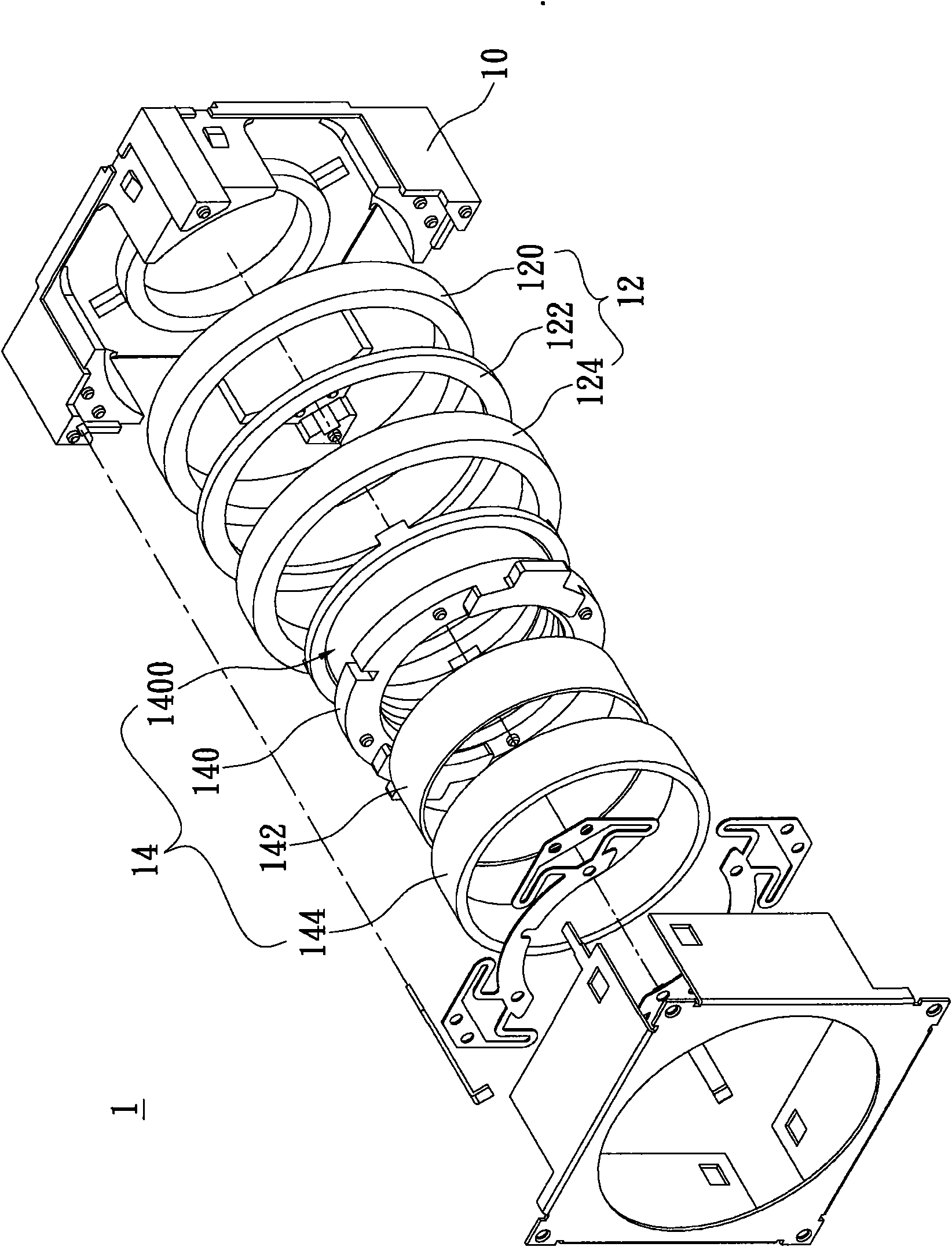

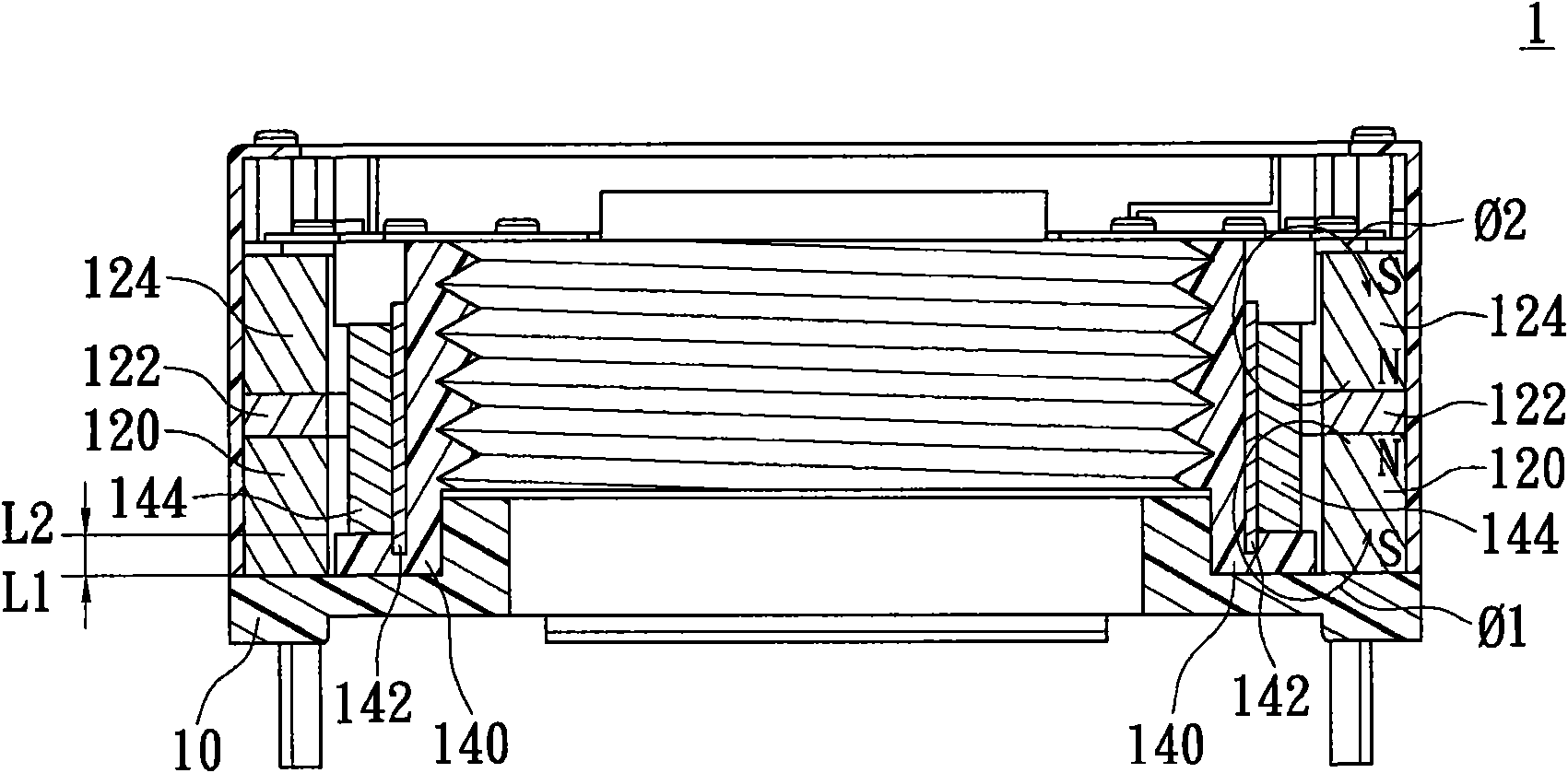

[0034] Please refer to figure 1 and figure 2 , figure 1 is a structural schematic diagram of the first preferred embodiment of the present invention, and figure 2 It is a structural sectional view of the first preferred embodiment of the present invention.

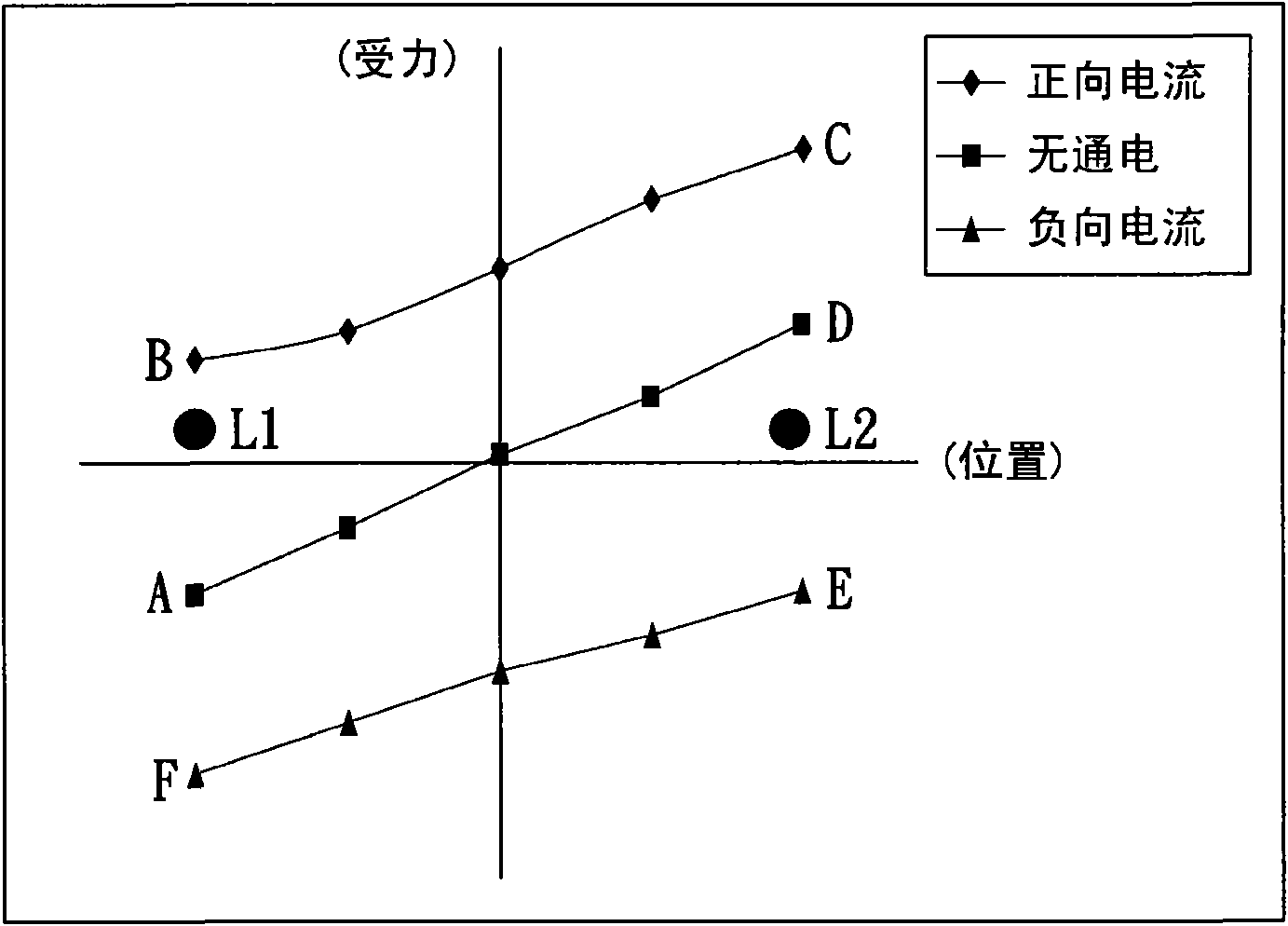

[0035] Such as figure 1 and figure 2 As shown, the lens actuator 1 of the present invention includes a base 10 , a hollow magnetic element 12 , and a lens carrier element 14 . Meanwhile, the hollow magnetic element 12 includes a first hollow magnet 120 , a hollow conductive disc 122 and a second hollow magnet 124 . Wherein, the hollow magnetic disk 122 has a first coupling surface (not marked) and a second coupling surface (not marked), and the first coupling surface is magnetically coupled to the first hollow magnet 120, and the second coupling surface is magnetically coupled to the second coupling surface. Hollow magnet 124. In addition, the first hollow magnet 120 and the second hollow magnet 124 are magnetica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com