Iron-core shielding roller type electromagnetic stirring sensor

An electromagnetic stirring and inductor technology, applied in the field of electromagnetic stirrers, can solve the problems of reducing the ampere-turns and magnetic permeability area of a roller electromagnetic stirring device, low efficiency of active magnetic field, reducing electromagnetic stirring force, etc., so as to solve the electromagnetic stirring force Insufficiency and inefficiency, solving low magnetic field efficiency, increasing the effect of electromagnetic stirring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

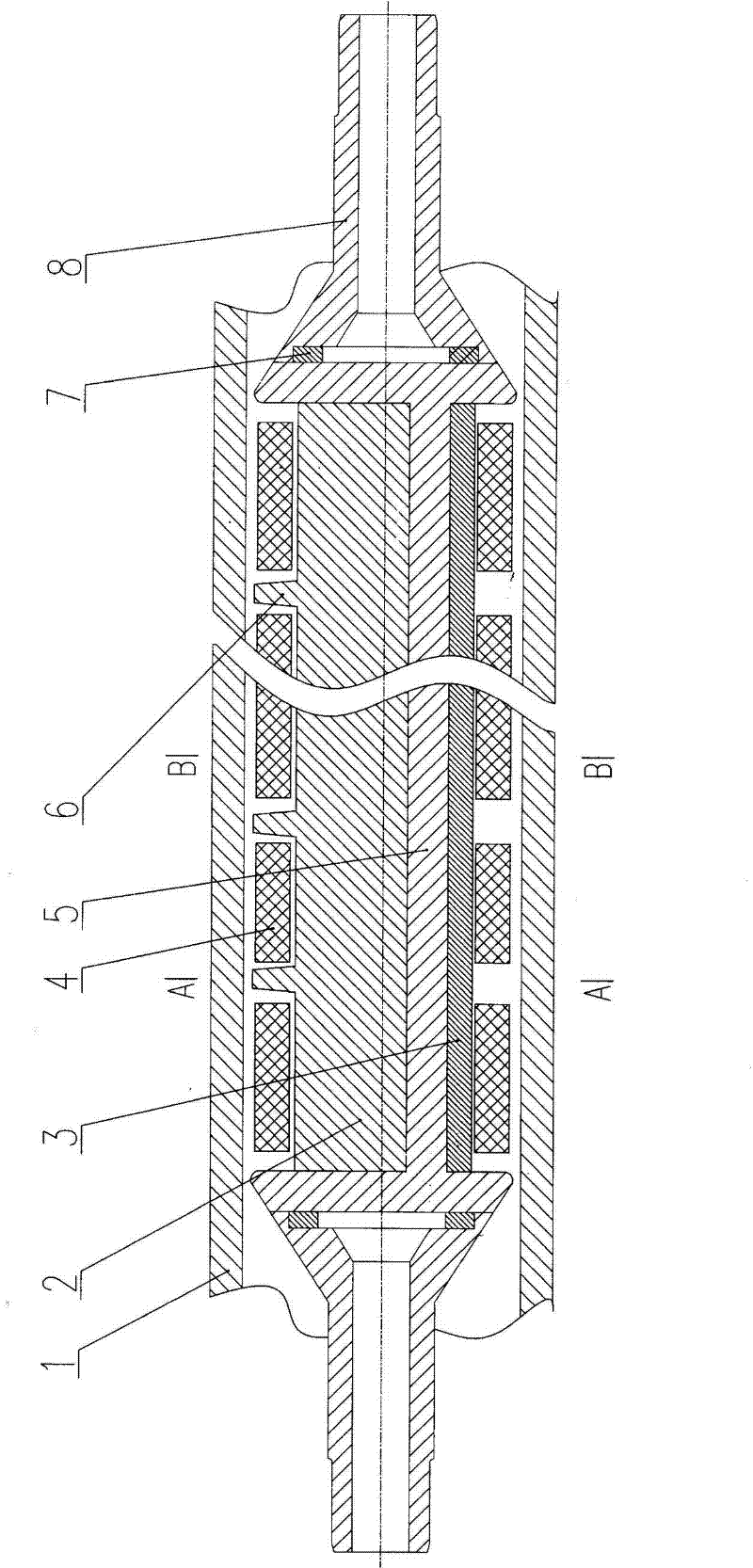

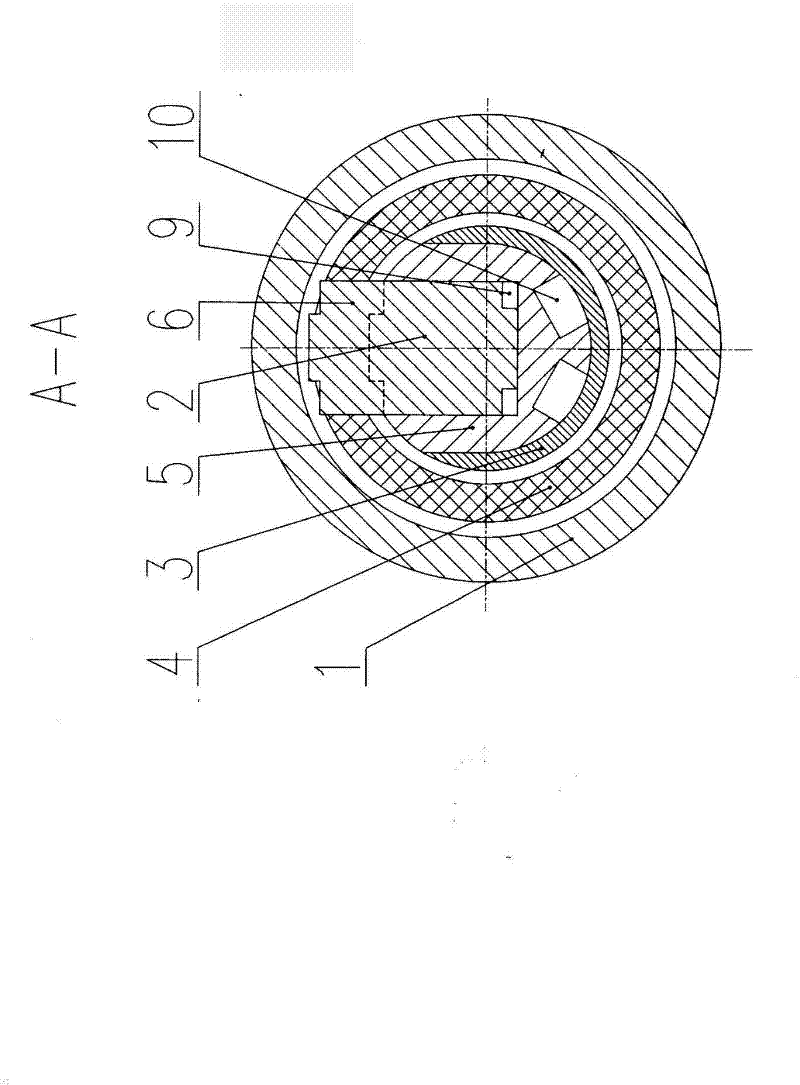

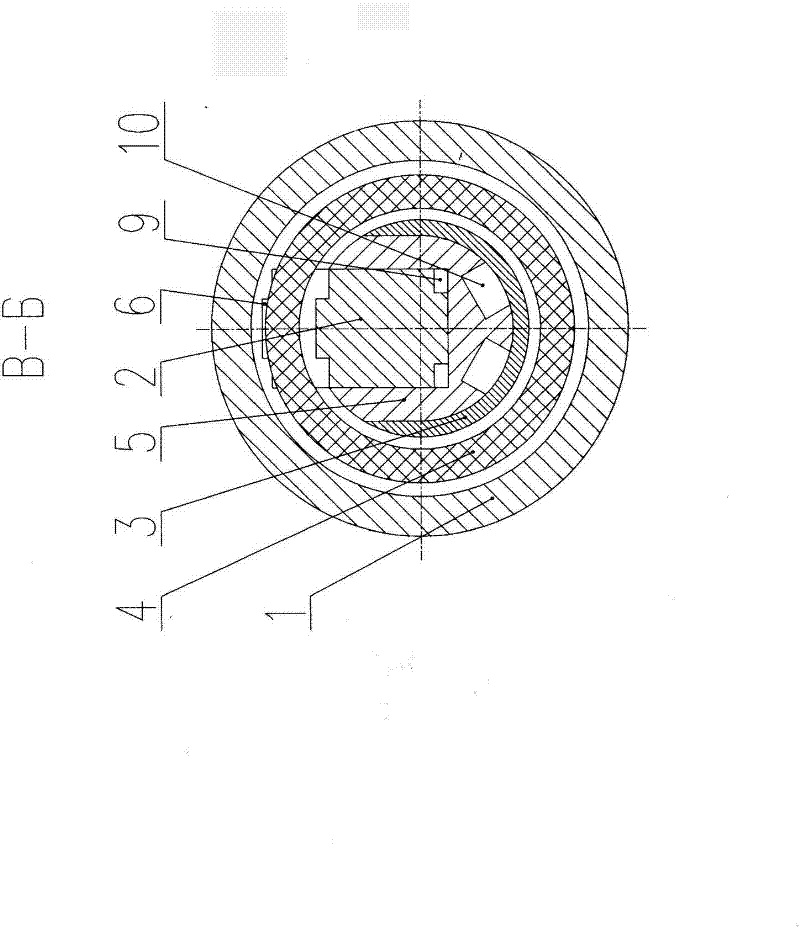

[0012] Depend on Figures 1 to 3 It can be seen that the present invention includes an iron core and a coil winding, wherein:

[0013] The iron core is a combined iron core, and the outer surface of the combined iron core is wound with a coil winding 4 in segmental gaps. The combined iron core and the coil winding 4 are arranged in the hollow roller 1 with gaps, and are fixed by the iron core shaft ends 8 provided at both ends. Combined iron core and coil winding 4 and hollow roller 1 rotate relative to each other;

[0014] The combined iron core includes an iron core composed of a main iron core 2 and a secondary iron core 5, a U-shaped shielding ring 3 wrapped around the outside of the secondary iron core 5 and the inside of the coil winding 4, and a shielding ring 3 arranged on the iron core and the coil winding 4 O-shaped shielding rings 7 at both ends, wherein the magnetic poles 6 are arranged between the coil windings 4 wound on the main core 2.

[0015] The U-shaped s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com