Belt-type magnetic separator

A technology of magnetic separator and frame, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of complex structure of magnetic separator, poor magnetic selection effect, low magnetic selection efficiency, etc., and achieve magnetic separation effect Good, low manufacturing cost, high magnetic selection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

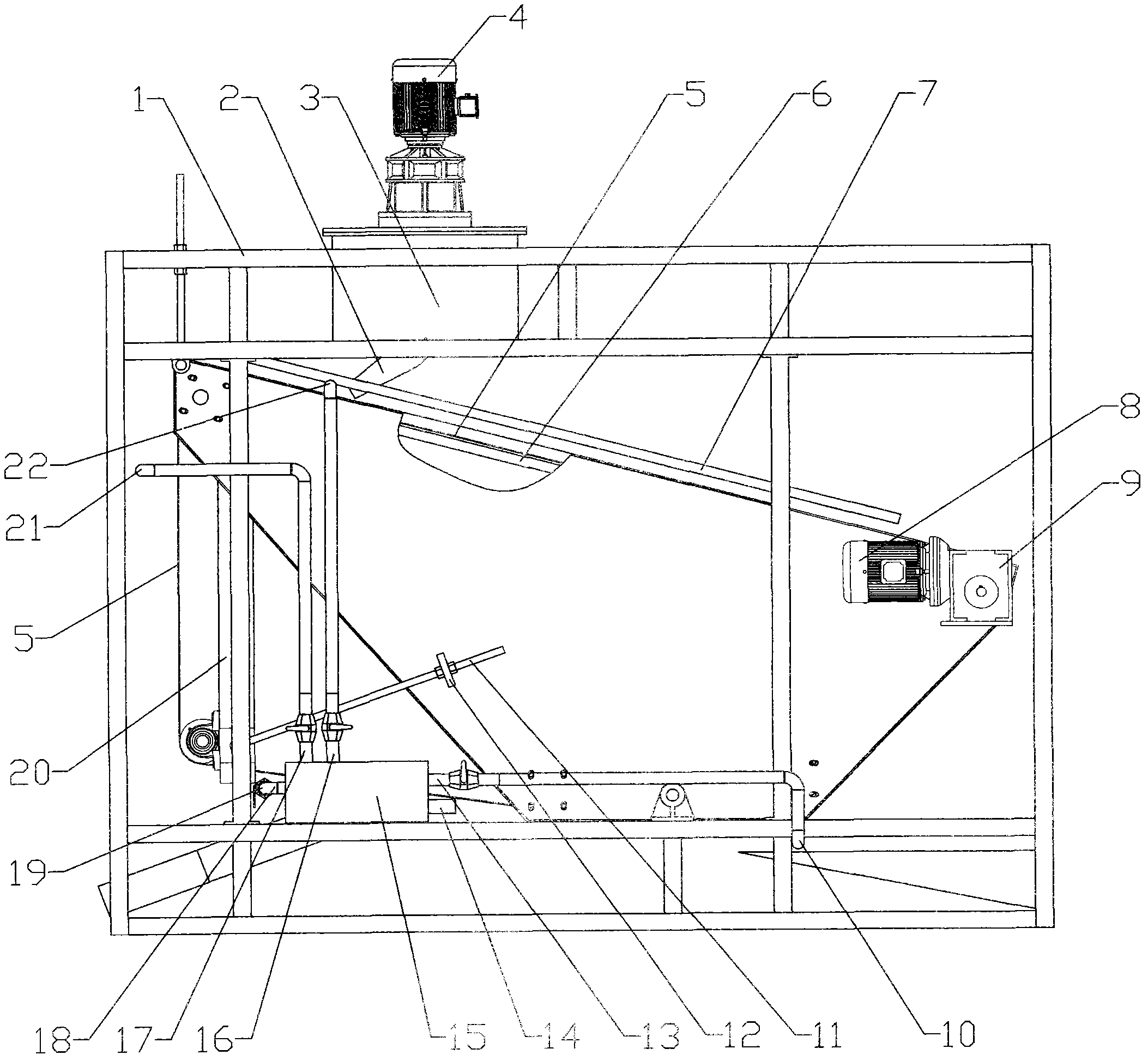

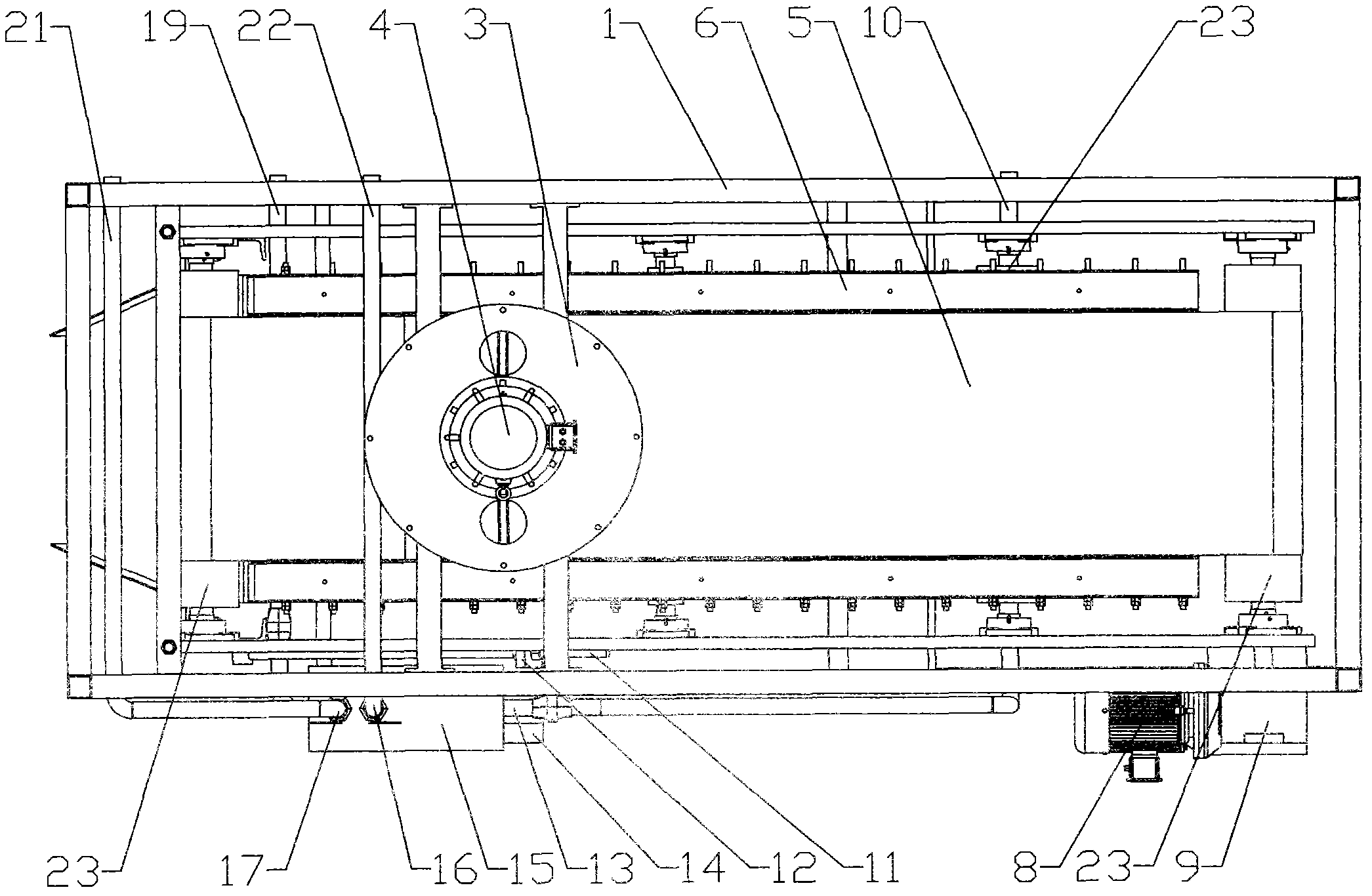

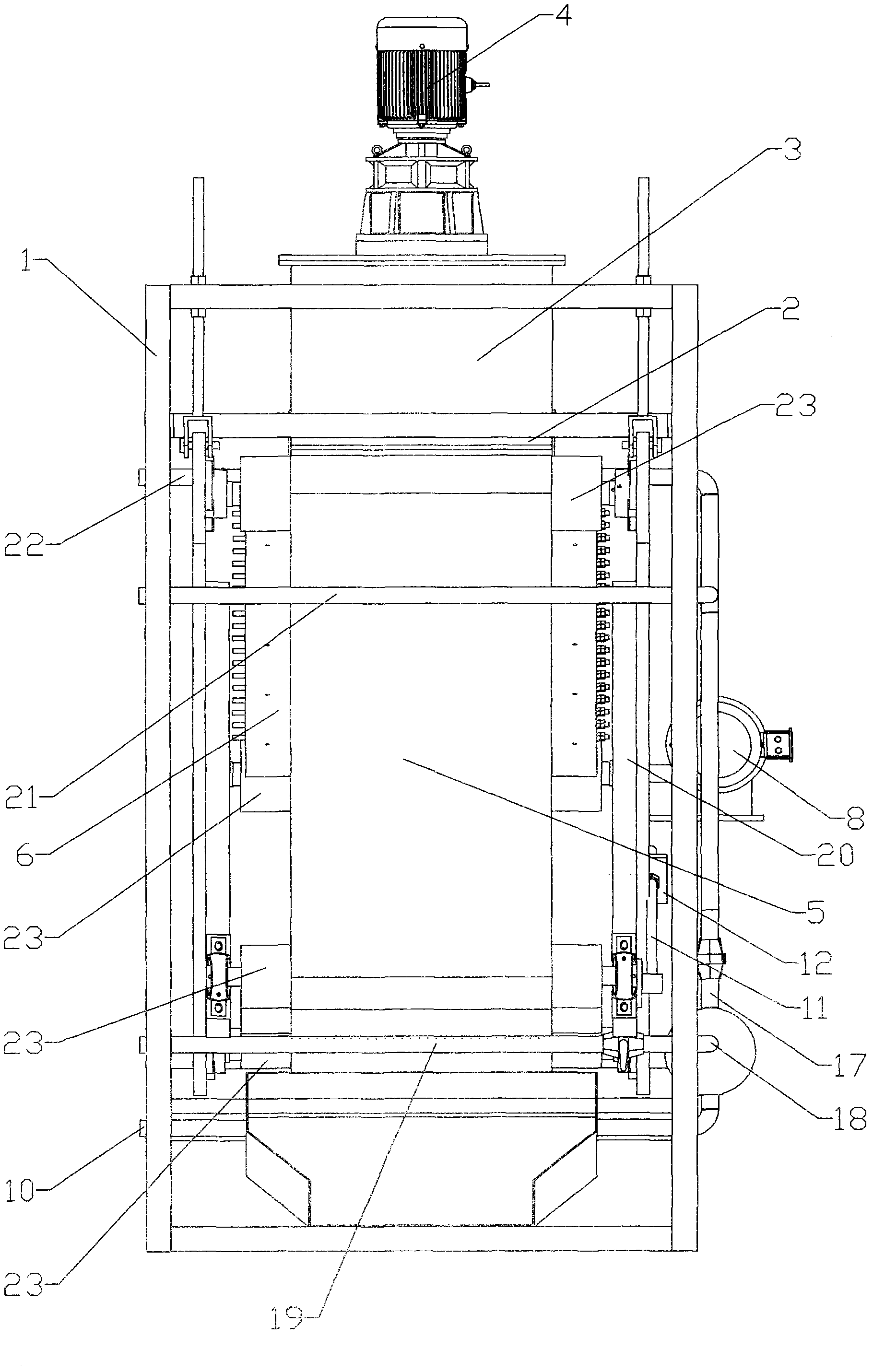

[0024] Example: as attached figure 1 , attached figure 2 And attached image 3 As shown, the belt type magnetic separator comprises a frame 1, a conveyor belt 5 is arranged on the frame 1, a feeding device is arranged on the top of the conveyor belt 5, a first magnetic system 6 is provided on the bottom of the conveyor belt 5, and the frame 1 is provided with a water spray device matched with the conveyor belt 5.

[0025] Conveyor belt 5 is positioned at the part inclined at feeding device place, and first magnetic system 6 is positioned at the bottom of conveyer belt 5 inclined part and is arranged along the length direction of conveyer belt 5, and feeding device is positioned at the higher end of conveyer belt 5, and conveyer belt The bottom of 5 is also obliquely arranged, and its inclination direction is identical with the inclination direction of top conveyor belt 5.

[0026] The unloading part of conveyor belt 5 is positioned at one end of frame 1 and is set up and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com