Punched sheet, iron core and motor

A punching and iron core technology, which is applied in the field of motors, can solve the problems of poor versatility and achieve the effects of simple and reasonable structure, cost reduction, and enhanced insulation structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

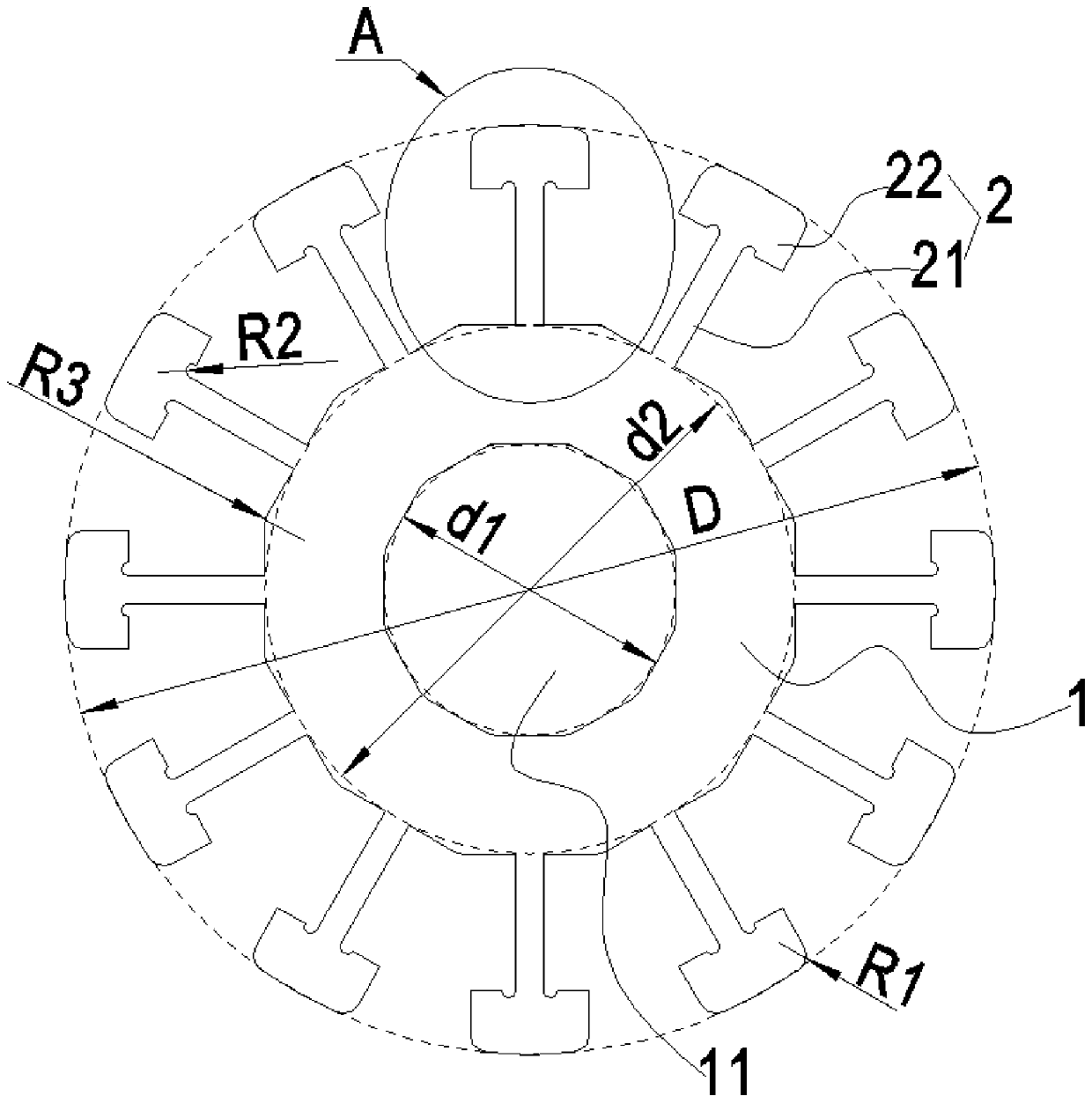

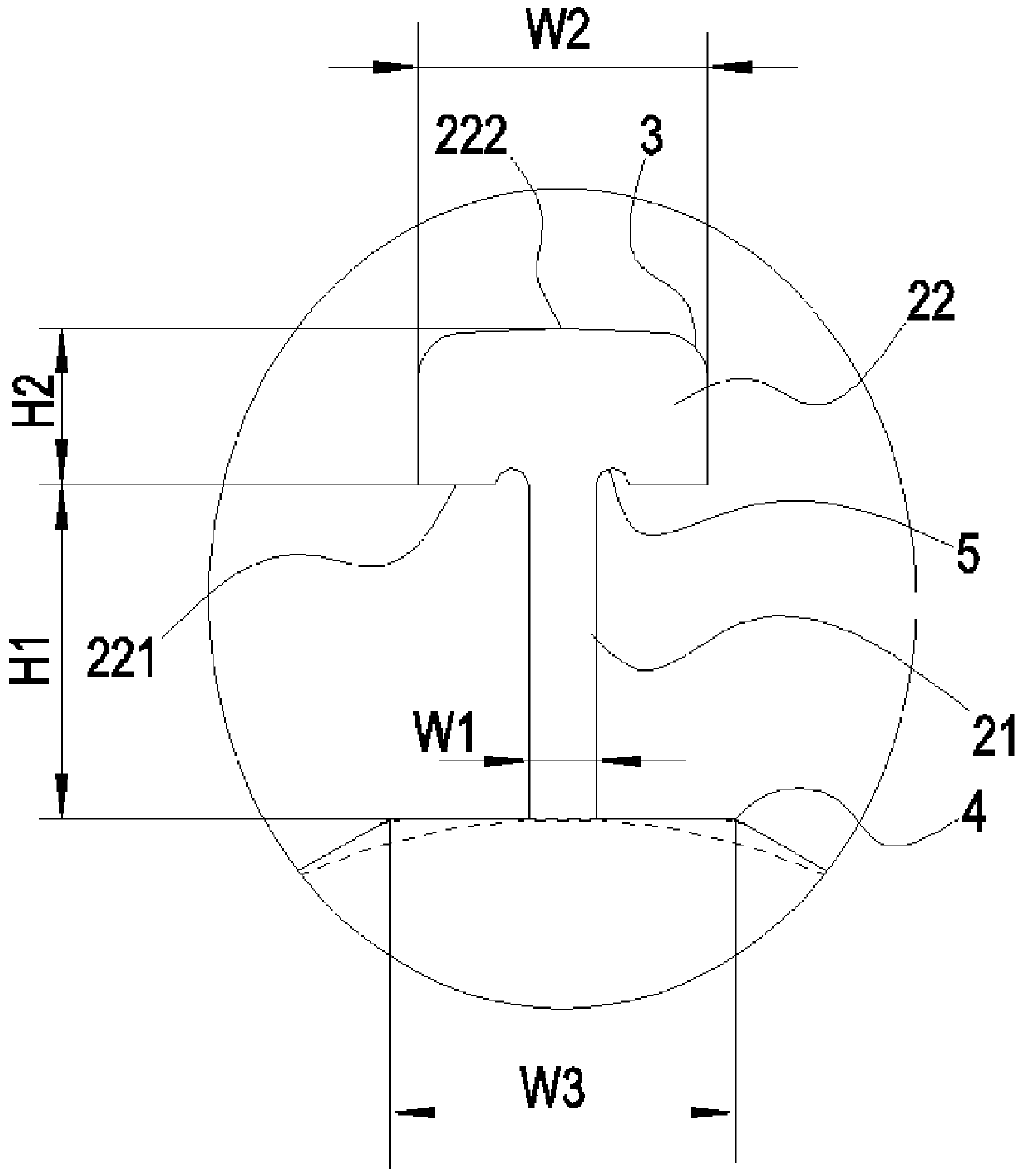

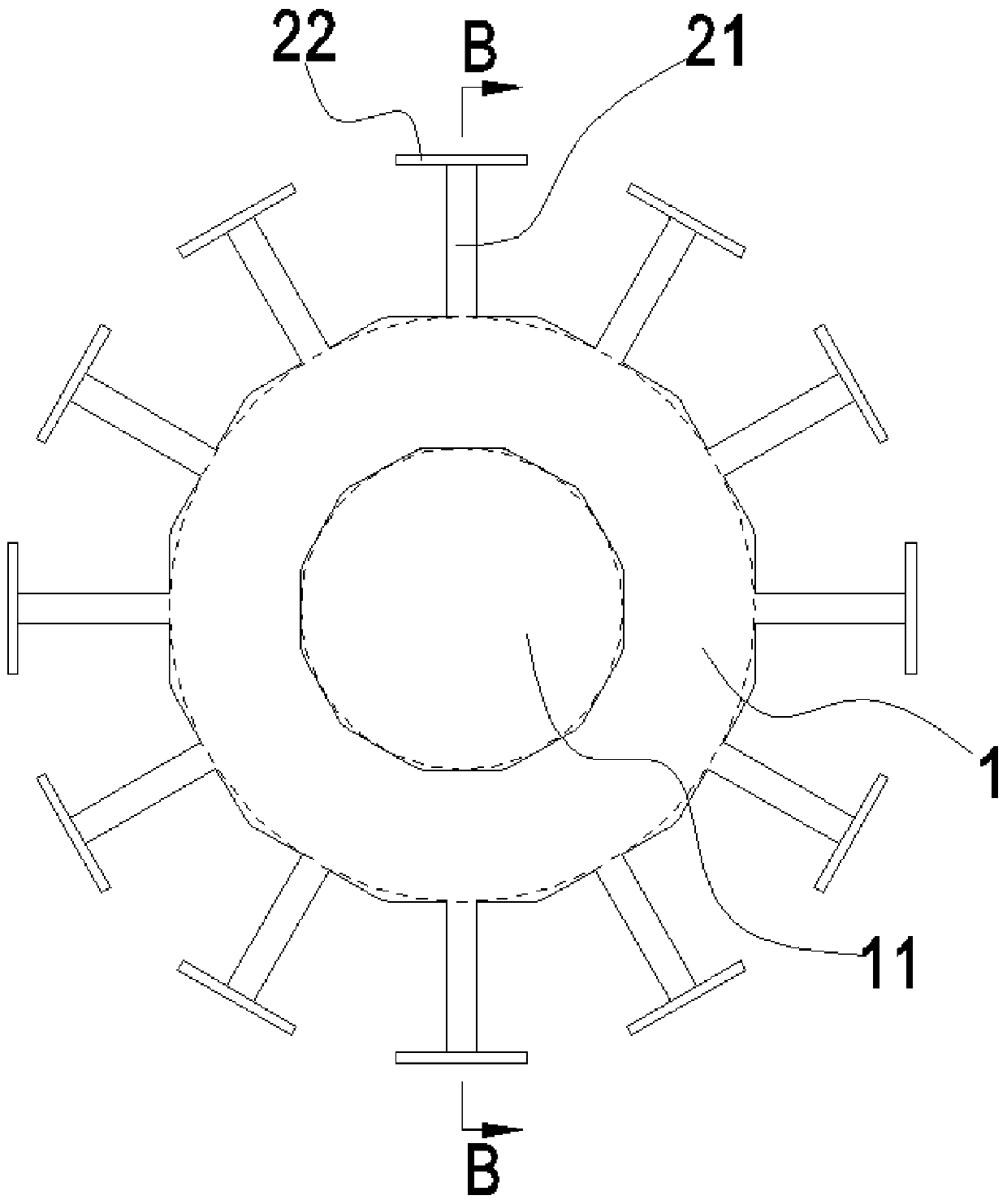

[0038] The present invention provides a punching sheet, which includes a punching sheet main body 1 and a plurality of tooth yoke bodies 2 uniformly distributed on the outer circumference of the punching sheet main body 1. It is worth noting that the punching sheet main body 1 and the tooth yoke main body 2 are integrally formed. . The tooth yoke main body 2 includes a tooth body part 21 connected to the punch body 1 and a tooth end part 22 connected to the end of the tooth body part 21, and the tooth yoke main body 2 is composed of a tooth body part 21 and a tooth end part 22. , the tooth body portion 21 is connected to the middle position of the tooth end portion 22 , that is, the sections of the tooth end portion 22 located on both sides of the tooth body portion 21 are symmetrical.

[0039] The total width and total length of the tooth end portion 22 are respectively W2 and H2, the tooth body portion 21 is a square sheet structure and the length and width of the tooth body...

Embodiment 2

[0042] This embodiment is a best implementation mode of Embodiment 1. The punching body 1 in this embodiment is a regular polygonal structure, and the center position of each side of the facing structure is respectively provided with the above-mentioned tooth yoke main body 2, In this way, the side connecting the tooth yoke main body 2 is straight. In this embodiment, the side of the tooth end portion 22 close to the punch body 1 is a plane 221 , and the plane 221 is parallel to the side corresponding to the regular polygonal structure. With this structure, a rectangular winding chamber is formed between the tooth end portion 22 and the corresponding side of the regular polygonal structure, so that the coils wound in the chamber can be more evenly placed in each position of the chamber.

[0043] Certainly, the above punching body 1 may also have a circular structure.

[0044] More preferably, in this embodiment, the side length of the punching body 1 is defined as W3, W3≥(4 / 5...

Embodiment 3

[0046] This embodiment is a more optimal implementation mode of Embodiment 2. The center of the punching body 1 in this embodiment is provided with a through hole 11. The through hole 11 can be a circular hole or a regular polygonal hole, and the through hole 11 is limited. The diameter of the hole 11 is d1, and the diameter of the inscribed circle that limits the punching body 1 is d2, the diameter of the entire punching sheet is D (also the diameter of the circumscribed circle of the entire punching sheet is D), d2>(1 / 2)× D, d1>(1 / 2)×d2.

[0047] As another implementation of this embodiment, the center of the punching body 1 is solid, that is, the through hole 11 is not provided.

[0048]It should be noted that a specific implementation of this embodiment is as follows: the surface of the side of the tooth end portion 22 away from the punch body 1 is parallel to the plane 221 . As a preferred implementation of this embodiment, the surface of the tooth end portion 22 away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com