Pivoting structure of tool receiving cabinet

A technology of tool storage and rotation device, applied in the field of pivot structure, can solve the problems of tool falling, less tool slot, large friction coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

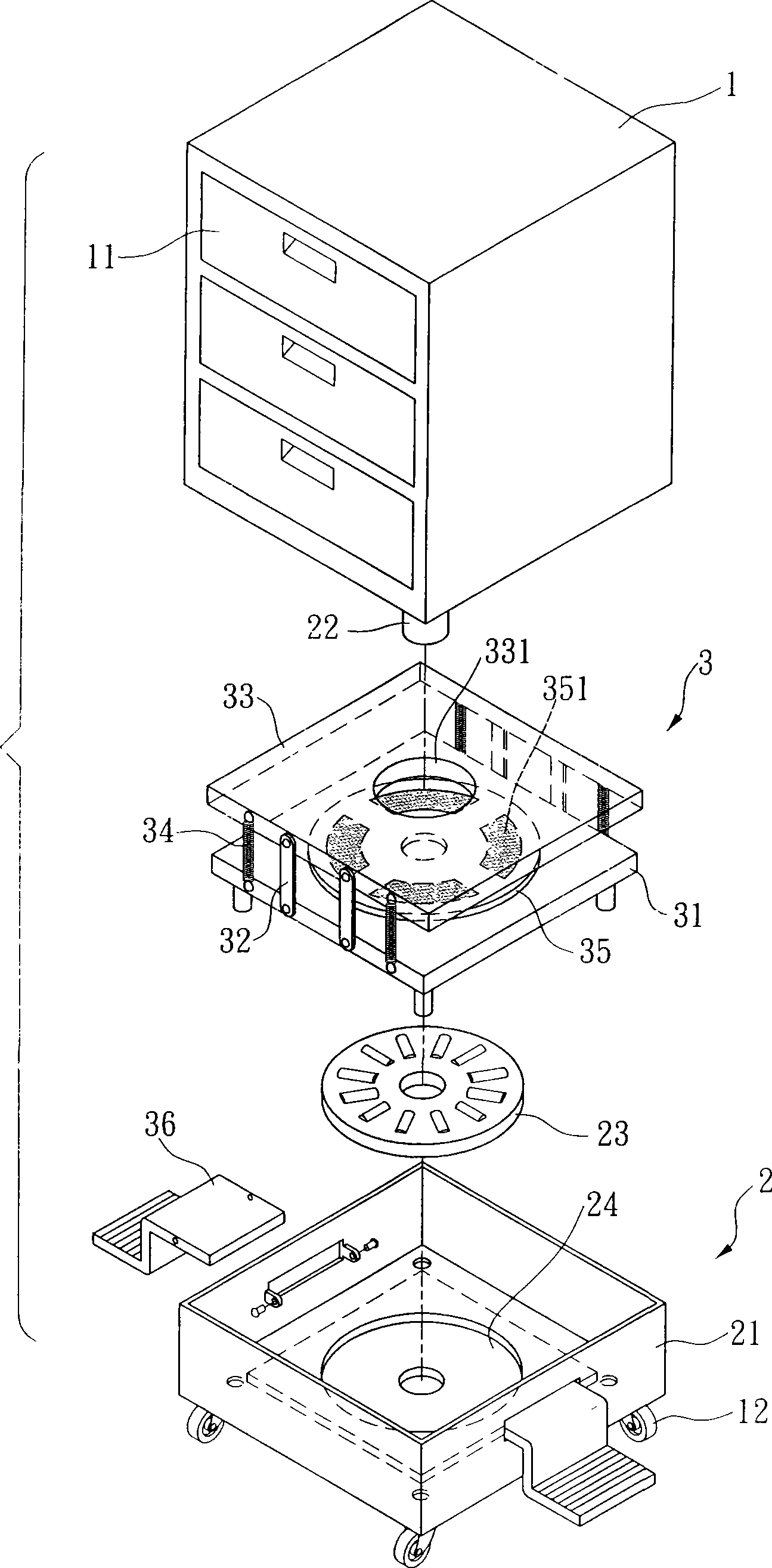

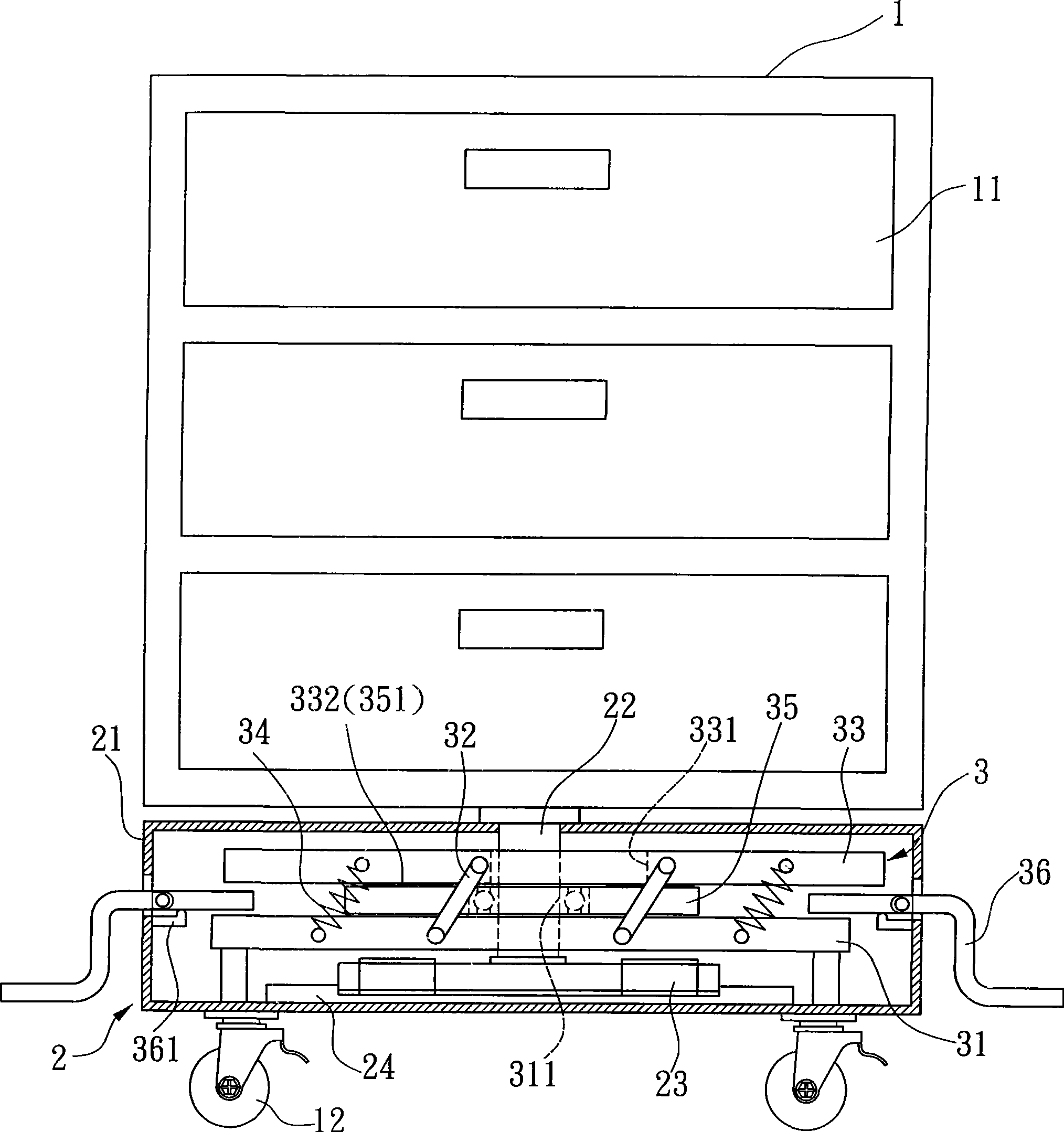

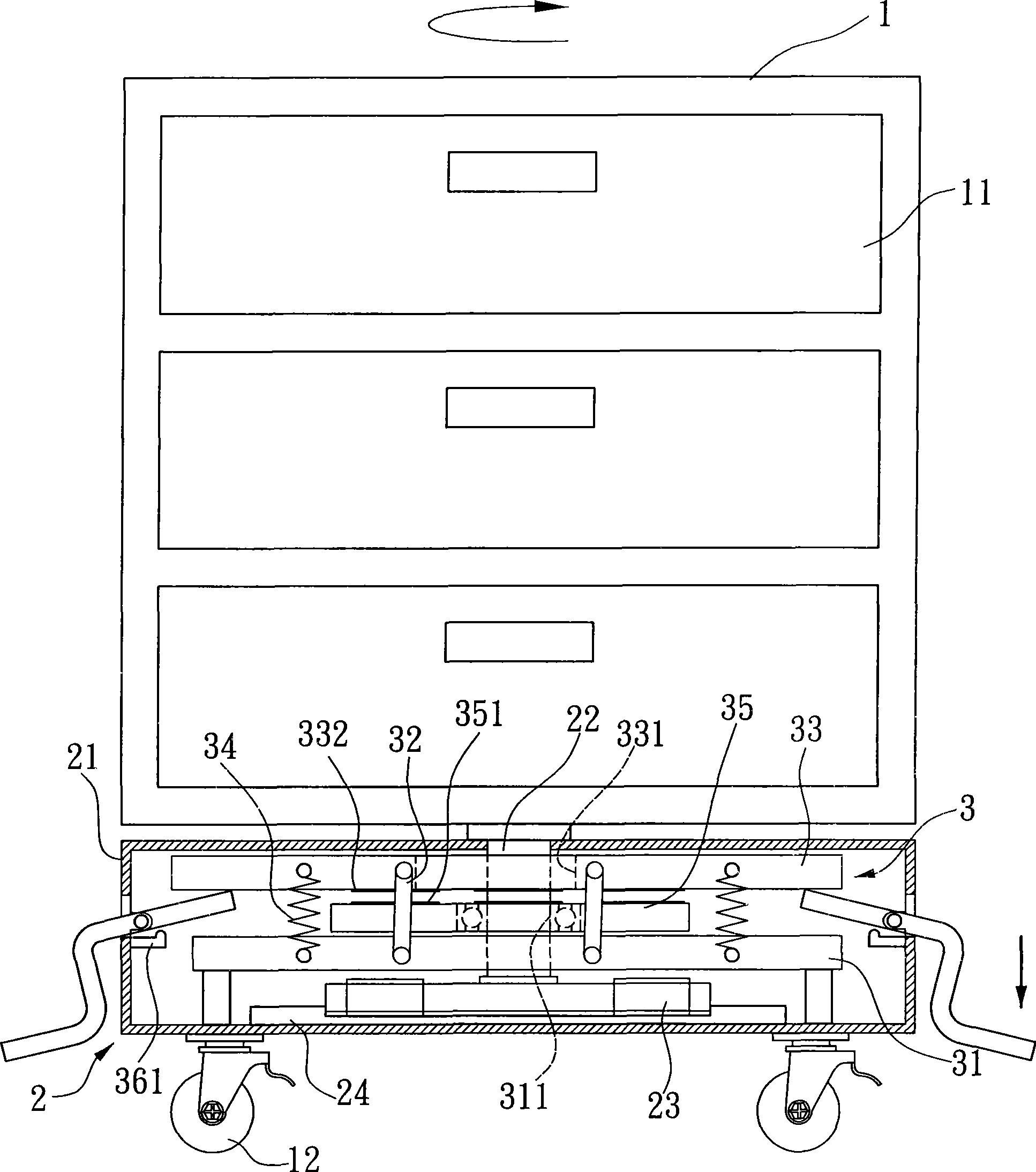

[0035] see Figure 1 to Figure 7 , shown in the figure is the selected embodiment structure of the present invention.

[0036] The present invention is a rotating device for a tool storage cabinet, which has more than two wheels that can be rolled along a circular track, or can be rotated at the joints, so that a tool storage cabinet can be rotated by external force. It can perform autorotation and reduce the radius of gyration required for rotation.

[0037] The tool storage cabinet is a box-shaped or cabinet-shaped body, which is designed to accommodate various hand tools or electric tools through the design of accommodating chambers or drawers, so that users can take them out and use them according to their needs.

[0038] The above-mentioned rotating device is a controllable wheel set, which has more than one wheel body, and each wheel body can be adjusted to roll forward, backward or turn, or be adjusted to roll along a circular track. Driven by an external force, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com