Wrench suitable for T-shaped groove of cast iron platform

A technology of cast iron platform and wrench, which is applied in the field of wrenches, which can solve the problems of wrench hurting hands and hexagonal bolts unable to reach the tightening torque, so as to avoid time-consuming problems, improve operation safety, and automatically adjust the tightening torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

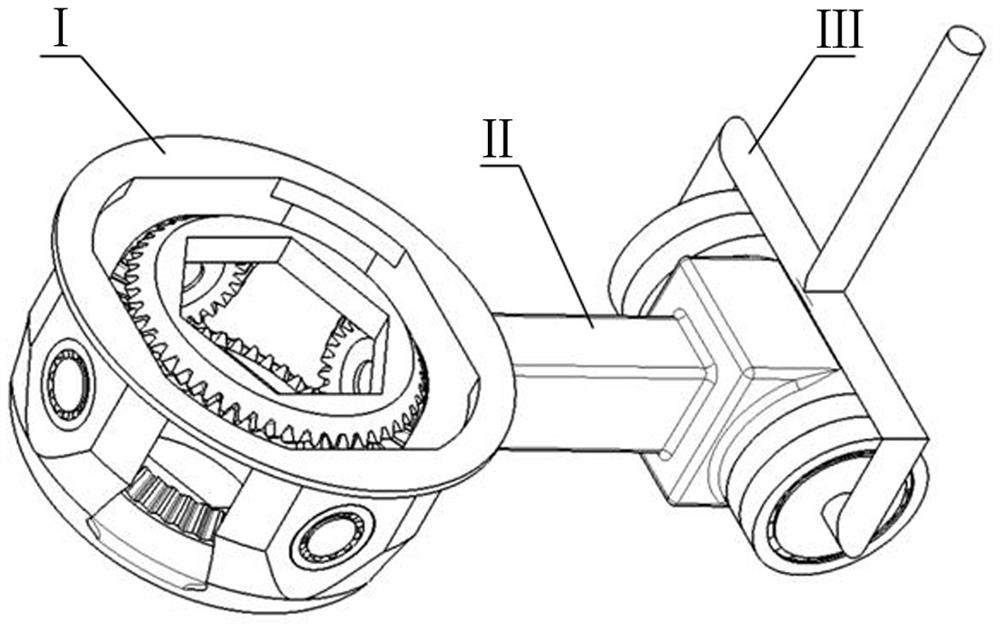

[0034] Embodiment 1: In this embodiment, the rotation axis of the clamping mechanism and the rotation axis of the power part are vertical in the space, that is, when the clamping mechanism is screwing the bolt, the rotation axis of the clamping mechanism is a vertical axis, perpendicular to the cast iron The surface of the platform, at this time, the axis of rotation of the power part is horizontal and parallel to the surface of the cast iron platform.

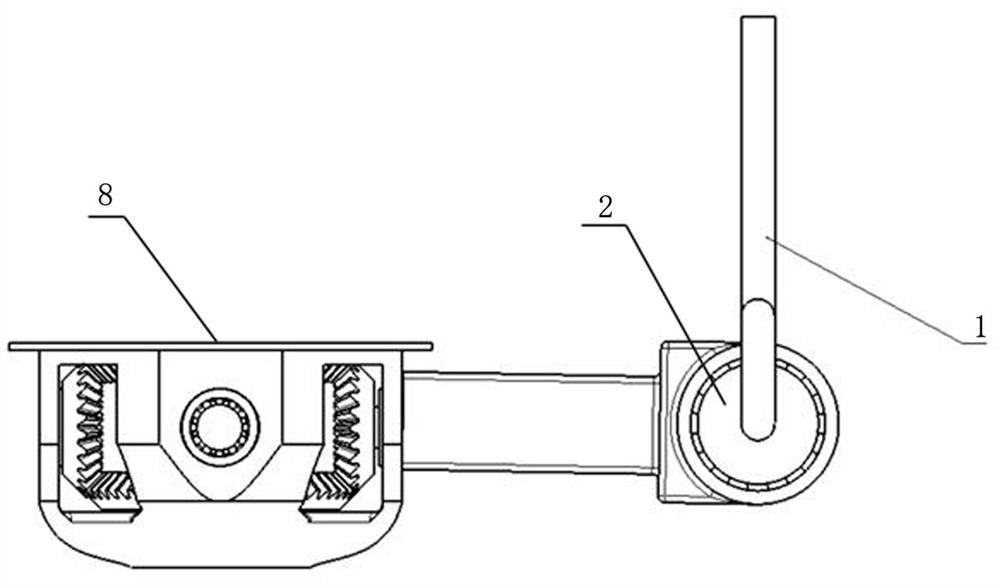

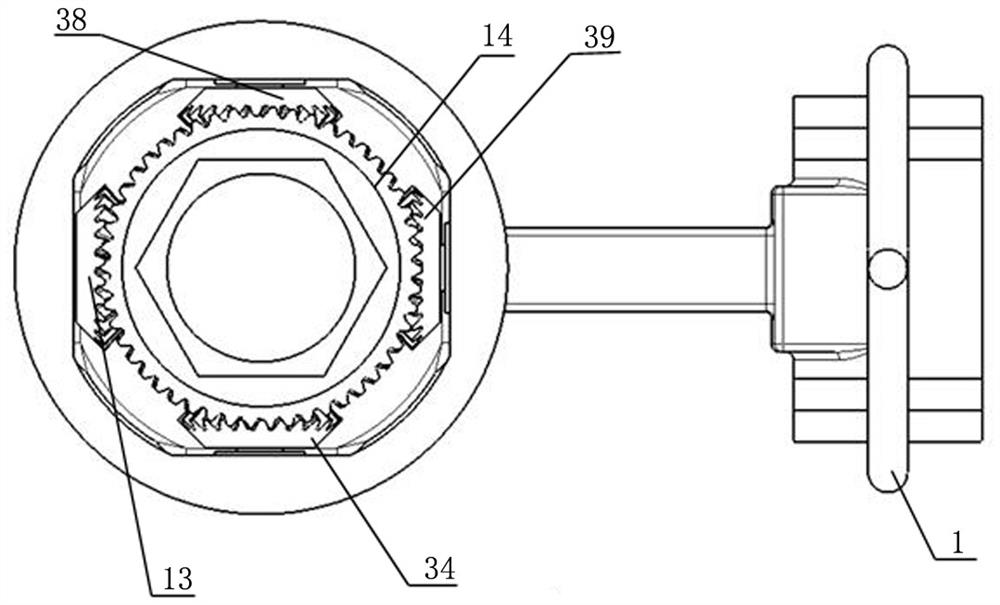

[0035] For the structure of the wrench in this embodiment, please refer to the attached Figure 2-7 , the working part is provided with a hollow clamping shell 8 for accommodating the clamping mechanism, and the upper and lower end surfaces of the clamping shell 8 are respectively provided with through holes for bolts to pass through. The clamping mechanism includes a second fixed helical gear 14 located at the upper end of the clamping housing 8 and a first fixed helical gear 9 located at the lower end of the clamping housing...

Embodiment 2

[0051] Embodiment 2: as Figure 8-11 , in this embodiment, the rotation axis of the clamping mechanism and the rotation axis of the power part are parallel in space, that is, when the clamping mechanism is screwing the bolt, the rotation axis of the clamping mechanism is a vertical axis, perpendicular to the surface of the cast iron platform, At this time, the rotation axis of the power part is also perpendicular to the surface of the cast iron platform. However, due to the setting of the second transmission shaft, the rotation axis of the power part is away from the cast iron platform.

[0052] At this time, the handle 1 can be set in an L-shape, one end is connected to the inner ring of the reversing bearing at one end of the reversing housing, and the other end is used as a handle, so that the handle is higher than the surface of the cast iron platform, and it can be avoided during work. Open cast iron platform, thereby improving the safety of wrench use.

[0053] In this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com