Rim for a bicycle wheel made from composite material with a wear indicator and wheel comprising such a rim

A wear indicator and composite material technology, which is applied to wheels, bicycles, two-wheeled bicycles, etc. made of non-metallic materials, can solve the problems of unsatisfactory rim wear and weakened rims.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

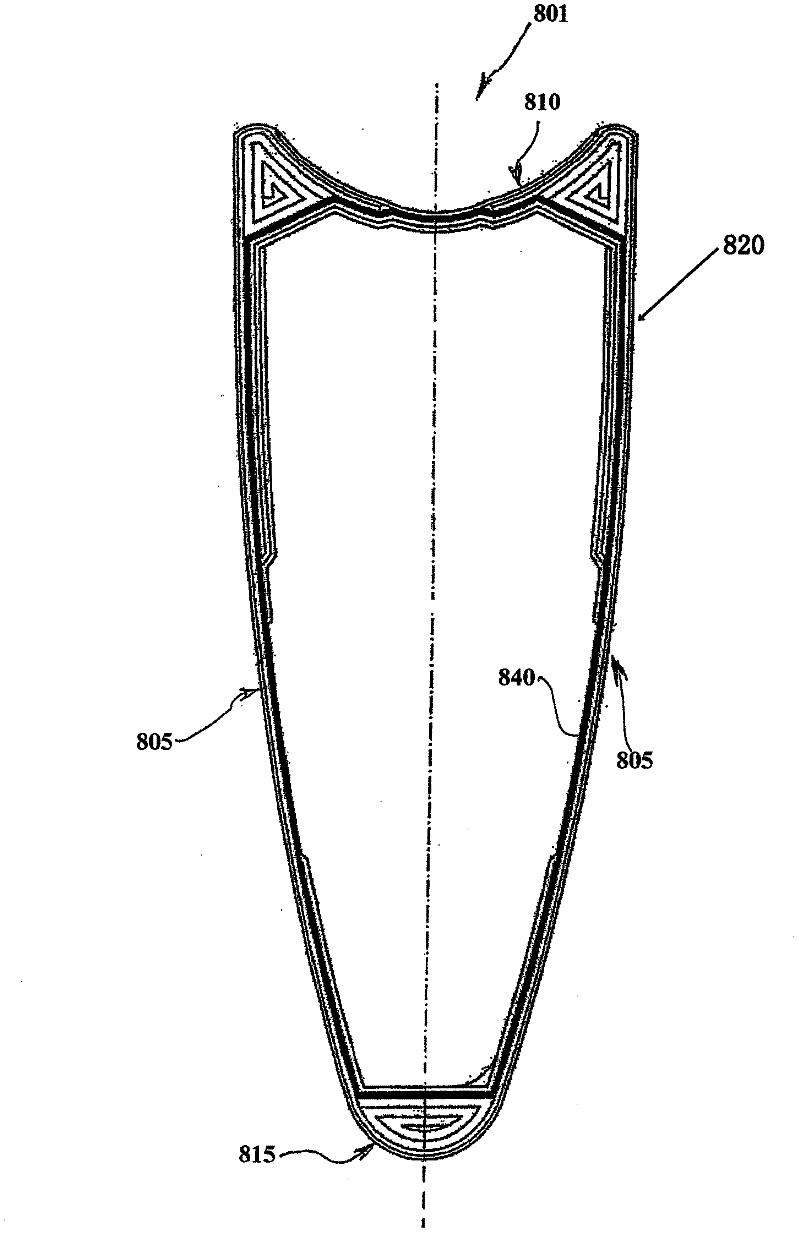

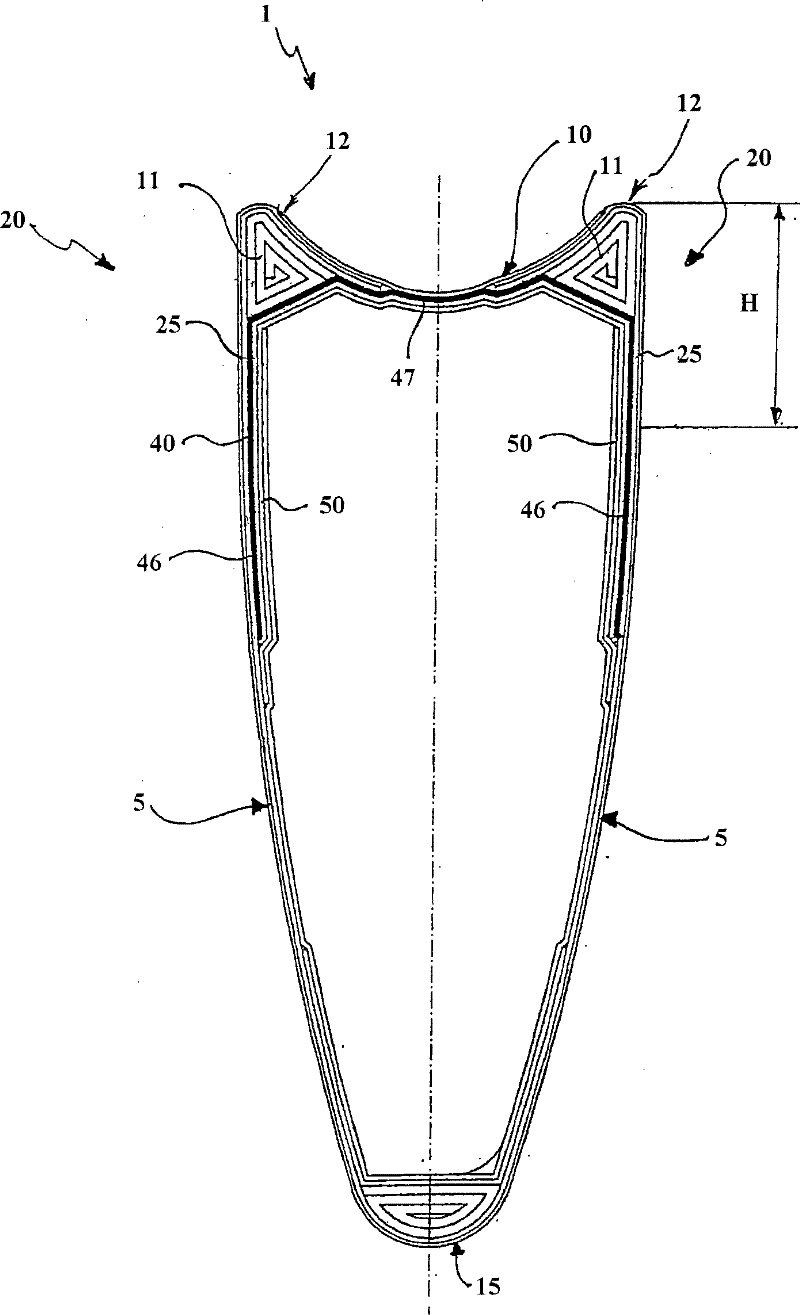

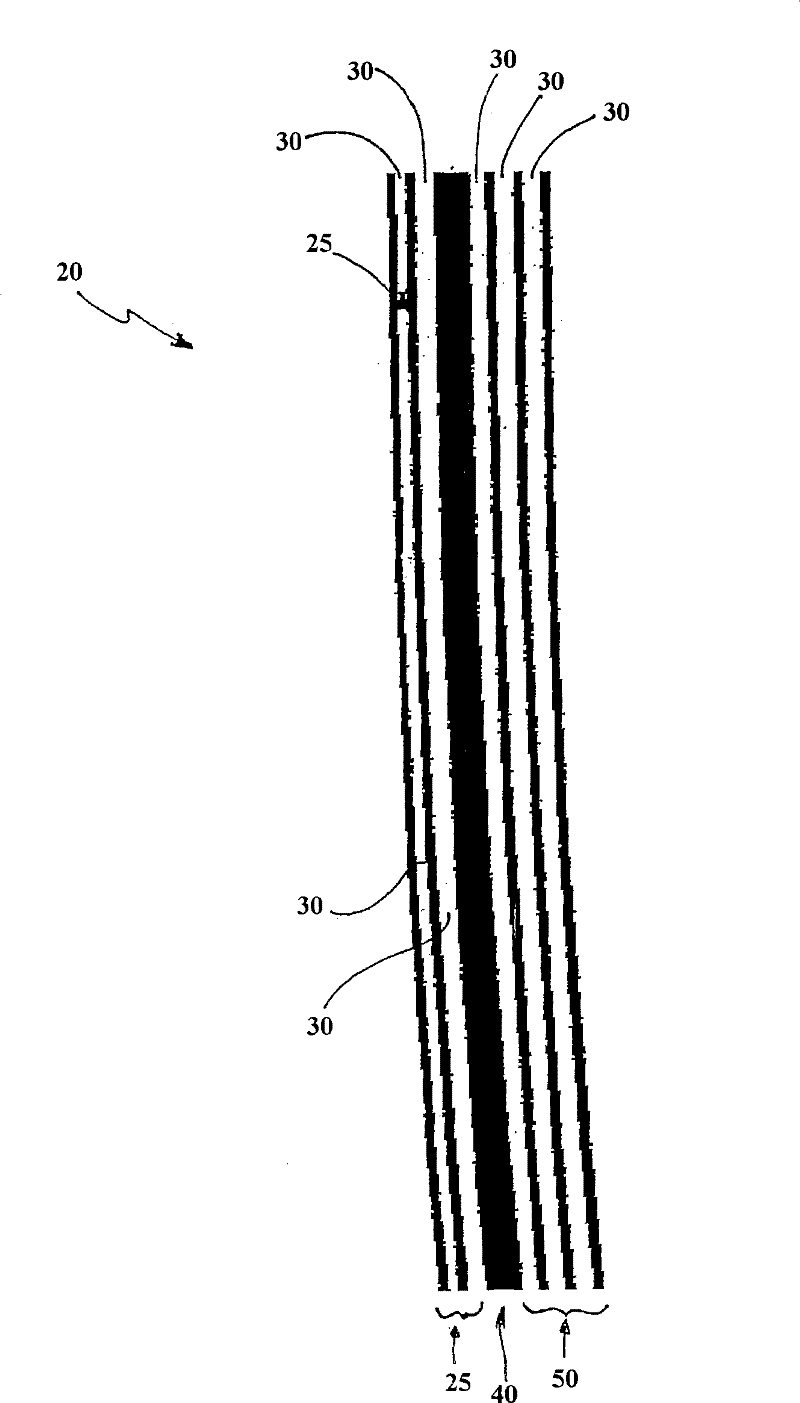

[0043] specific reference Figures 1 to 4 According to the invention, the rim 1 made of composite material comprises two lateral sides 5 connected by an upper bridge 10 and a lower bridge 15 so as to form a tubular support structure.

[0044] Each side 5 comprises a brake raceway 20 , which refers to the area where the brake pads of the bicycle on which the wheel comprising the rim 1 is mounted can act during braking. The rim 1 is of the so-called high profile type, ie has a pronounced extension in radial direction. The brake race 20 has a greater width than is used to accommodate the brake pads to allow for an acceptable range of positions. Typically, it can be considered that the brake race is the radially outermost part of the side 5 equal to a height H of about 10-12 mm, but of course different dimensions are possible. In order to counteract the action of the brake pads on the brake track 20 , the side surface 5 has a greater thickness at this raceway 20 than in other re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com