Valve actuating mechanism for internal-combustion engine capable of automatic phase conversion

A technology of gas distribution mechanism and internal combustion engine, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc. It can solve the problems of complex structure and inability to change the gas distribution phase, and achieve the effect of increasing or decreasing the exhaust phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

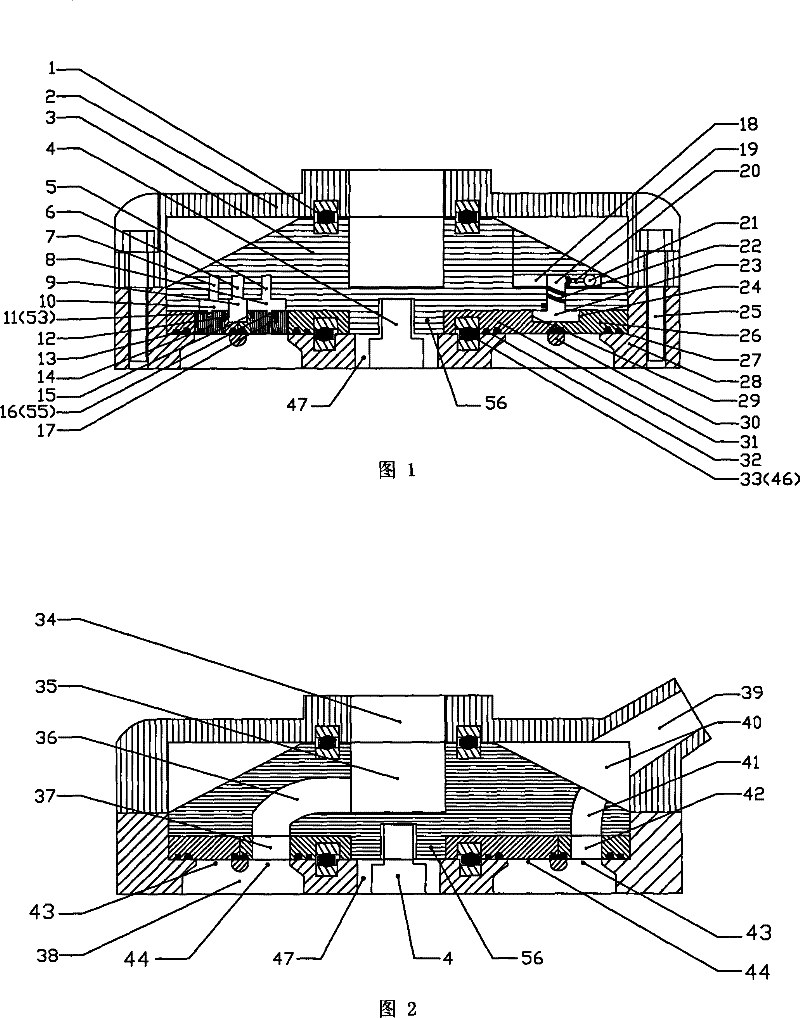

[0022] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

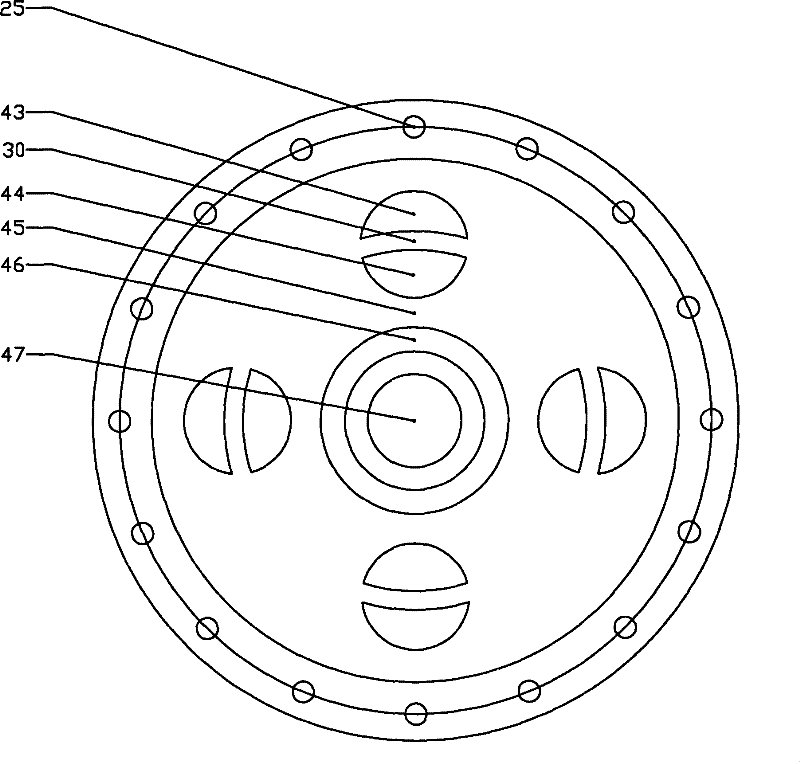

[0023] An automatic phase-changing internal-combustion engine gas distribution mechanism includes a combined turntable device, a phase-changing device and an air hole device. refer to Figure 1 to Figure 3 , the air hole device comprises an air inlet 44 and an exhaust hole 43 corresponding to each cylinder 38 on the upper end surface of the cylinder body 28, each air inlet 44 and each exhaust hole 43 are respectively arranged on a circle, each air inlet 44 and a vent hole 43 are correspondingly distributed radially from inside to outside. Each air inlet 44 and a corresponding air outlet 43 together form a circle, and the two are separated by an arc-shaped spacer bar 30 .

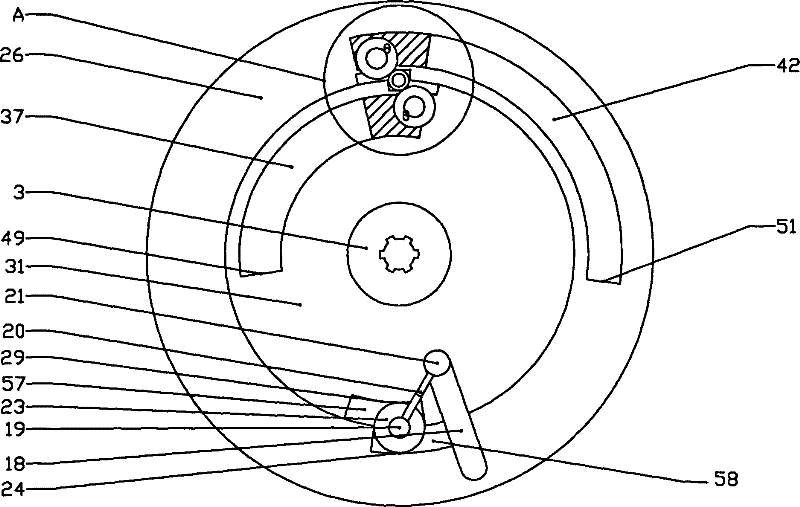

[0024] refer to figure 1 As shown in FIG. 2 , the combined turntable device includes a main turntable 3 , an intake disk 31 , and an exhaust disk 26 . The main turntable 3 is rotata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com