Combined service brake and stored-energy brake cylinder with internal ventilation

一种弹簧蓄能、制动缸的技术,应用在制动器、制动分泵、制动组件等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

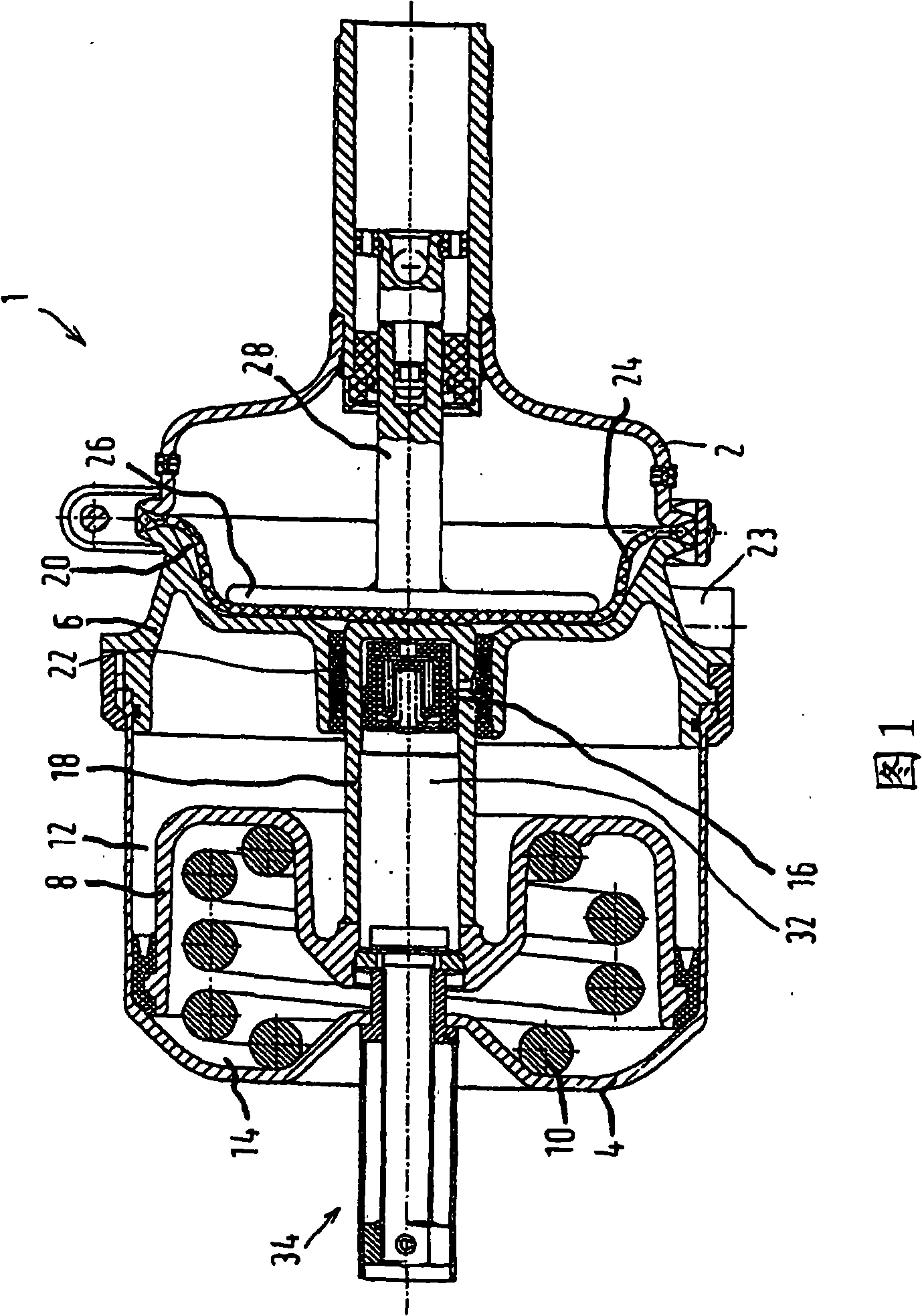

[0020] In order to explain the invention by way of example, FIG. 1 shows a combined service brake and spring-loaded brake cylinder 1 , referred to below as a combination cylinder. The combined cylinder comprises a working brake cylinder 2 and a spring-loaded brake cylinder 4 structurally and functionally associated with the working brake cylinder. Service brake cylinder 2 and spring-loaded brake cylinder 4 are separated from one another by an intermediate wall 6 . A spring-charged brake piston 8 is displaceably arranged in the spring-charged brake cylinder 4 , wherein a stored-charge spring 10 bears against one side of the spring-charged brake piston 8 . On the opposite side thereof, the energy storage spring 10 is supported on the bottom of the spring energy storage brake cylinder 4 . A spring-charged brake chamber 12 is formed between the spring-charged brake piston 8 and the intermediate wall 6 , which is connected to a pressure regulation module, not shown for reasons of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com