Motorcycle

A technology for motorcycles and car bodies, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of increased high-frequency components of exhaust sound and increased speed of sound.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Referring to the drawings, embodiments of the present invention will be described with reference to the drawings. In the following description, the upstream side and the downstream side are defined on the basis of the flow of exhaust gas.

[0039] (1) The structure of the motorcycle.

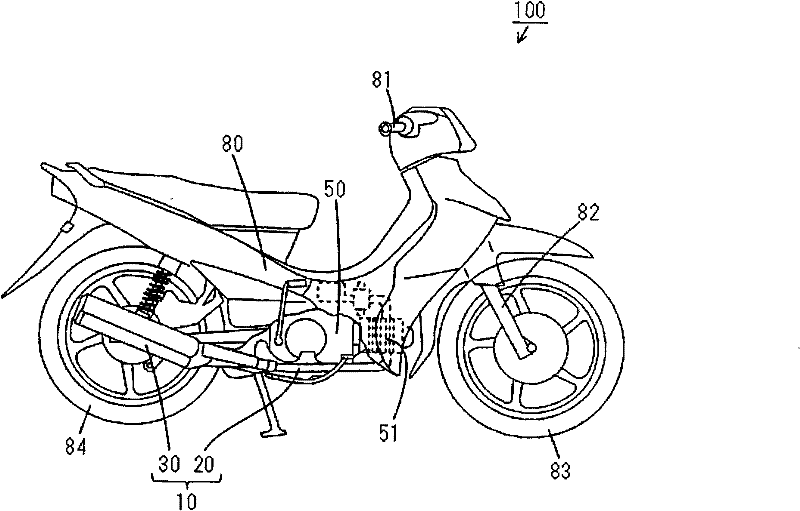

[0040] figure 1 is a side view of a motorcycle according to an embodiment of the present invention.

[0041] figure 1 The motorcycle 100 shown includes a body 80 comprised of a body frame and a frame cover. A head pipe (not shown) is provided at the front of the vehicle body 80, and a handlebar 81 is provided at the upper end of the head pipe. A front fork 82 is attached to the lower end of the head pipe. In this state, the front fork 82 is rotatable about the axis of the head pipe within a predetermined angle range. A front wheel 83 is rotatably supported on the lower end of the front fork 82 . Rear wheels 84 are rotatably supported at the rear of the vehicle body 80 . The single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com