Elevator guide rail manufacture method and adjusting device

A technology for adjusting equipment and elevators, applied to the manufacturing method of elevator guide rails and adjusting equipment, and improving the adjustment method before processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

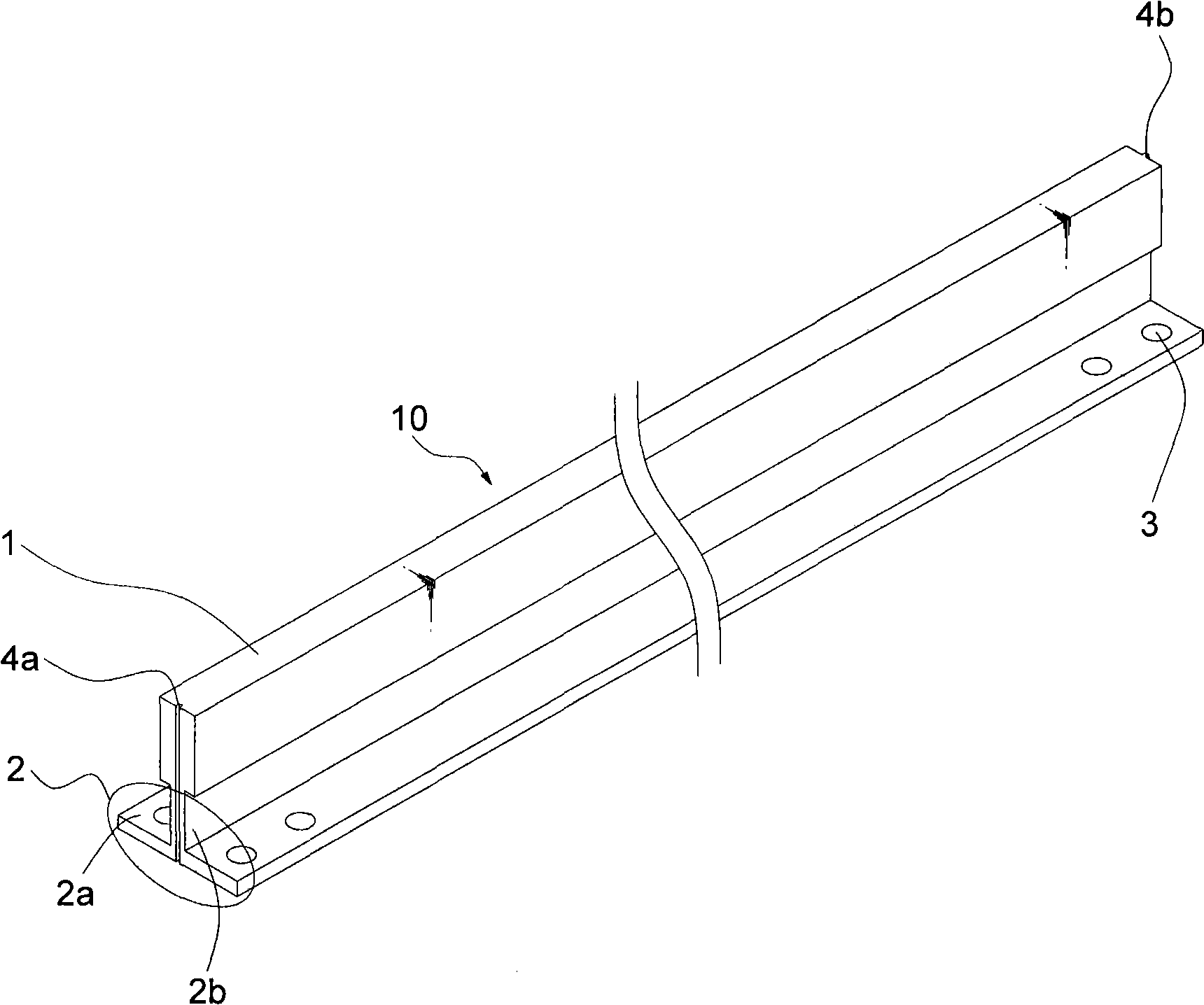

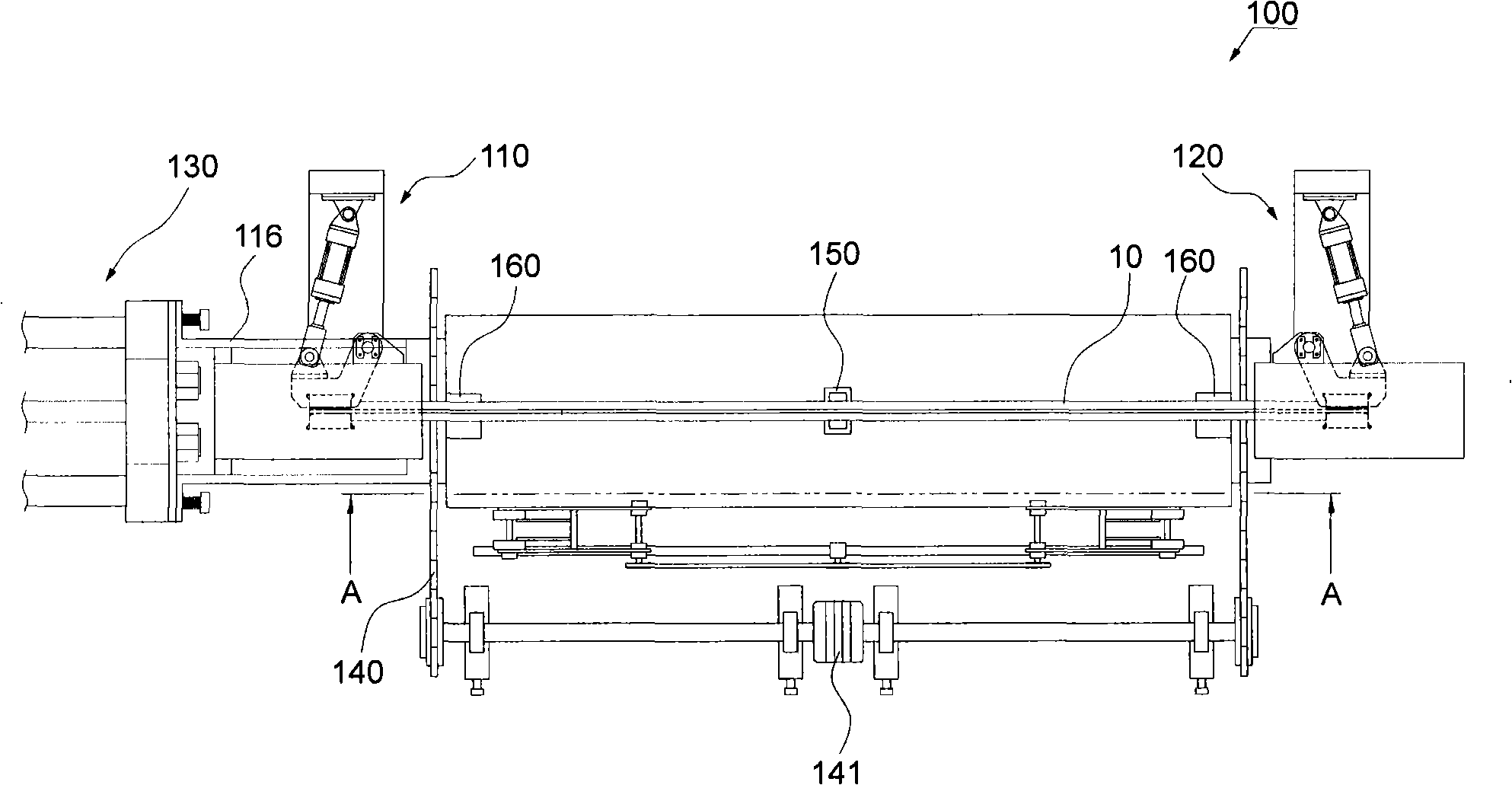

[0032] Next, the method for processing the elevator guide rail of the present invention will be described in further detail.

[0033] For reference, after finishing each process, the track manufactured according to the embodiment of the present invention is transported to the next process by common devices such as conveying rollers, conveyor belts, and hoists.

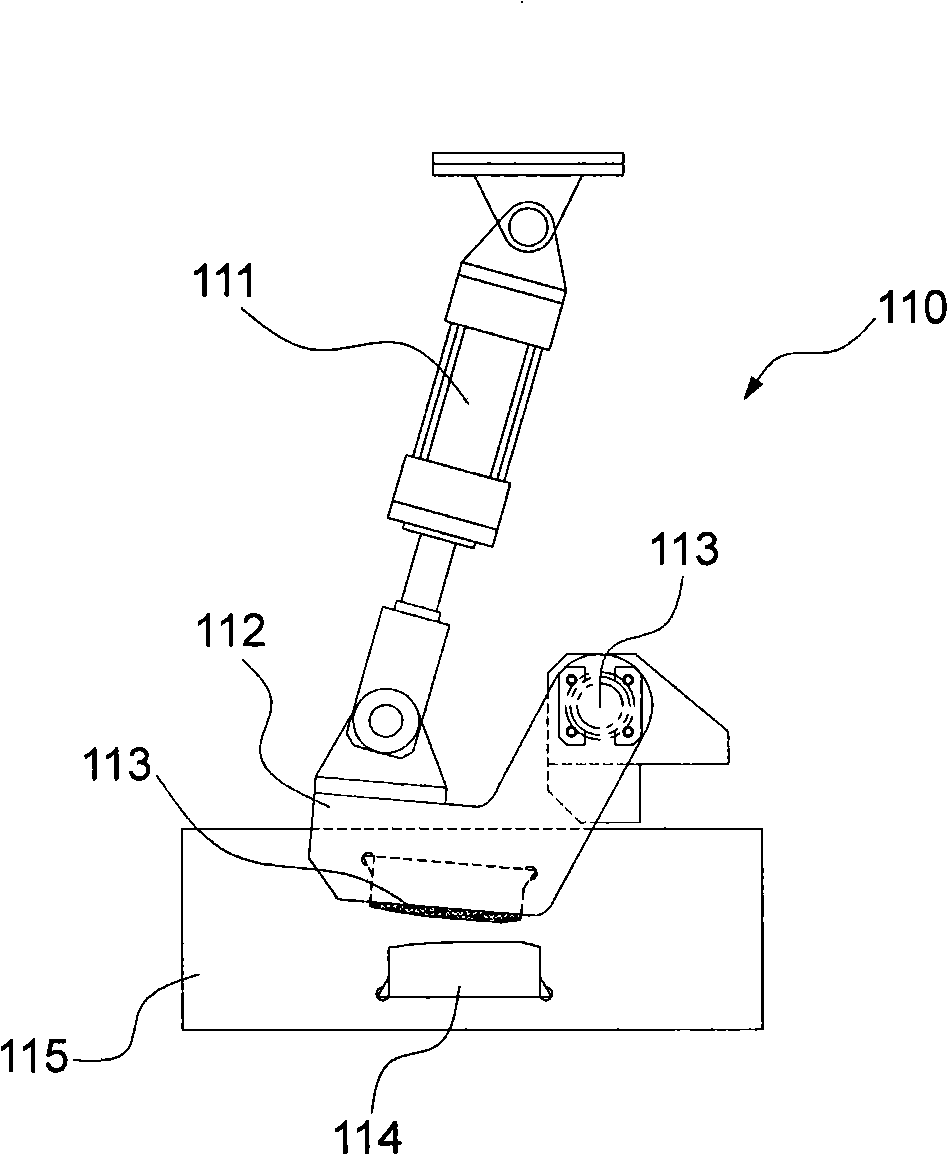

[0034] As the first step of post-processing, the track is adjusted for the first time to increase the verticality of the track. The track is obtained by pre-processing the billet and cut to a specified specification. The first adjustment is a stretch adjustment that fixes both ends of the track and pulls one end (traction). At this point, both ends, preferably one end, can be pulled to avoid applying unnecessary mechanical pressure to the rail and to simply remove the applied pressure (stretching adjustment step S1 ). Through the above adjustment, the track has a verticality of 0 to 3.5 [mm / 5m].

[0035] After the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com