Depolarized reflector

A mirror and depolarization technology, applied in condensers, optics, instruments, etc., can solve the problems of depolarization effect, narrow spectral band, and inability to adjust the incident angle of light at will.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

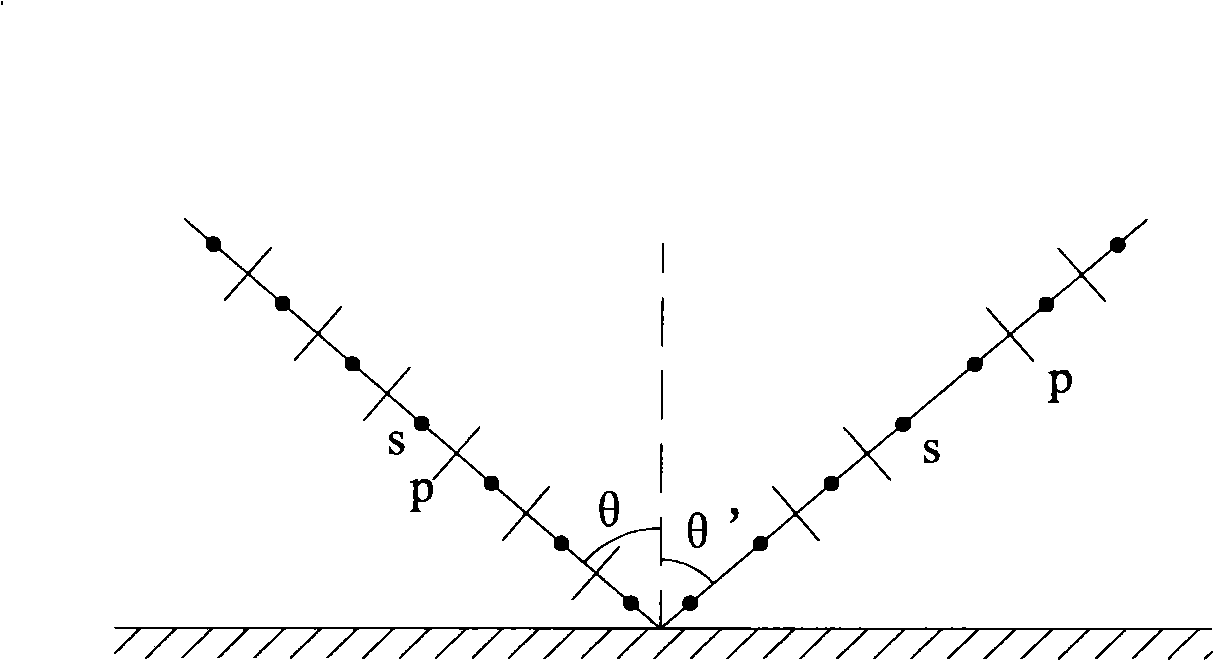

[0083] Such as image 3 A schematic diagram of an embodiment of the depolarizing reflector of the present invention is shown. The depolarizing reflector in this embodiment is only composed of one group of mirrors, that is, a polarizing reflector 1 and a compensating reflector 2 . The compensating reflector 2 directly receives the reflected light beam from the polarizing reflector 1 . The polarizing reflector 1 has the same optical performance as the compensating reflector 2, and the plane formed by the incident light 5 of the polarizing reflector 1 and the normal 6 of the polarizing reflector 1 is the polarizing incident plane, so that the compensating reflector 2 The plane formed by the incident light 7 and the normal line 8 of the compensating mirror 2 is the compensating incident plane, and the incident angle θ of the polarizing mirror 1 1 After the polarized incident plane and the polarized incident plane are determined, the orientation of the compensation mirror can be u...

Embodiment 2

[0085] Such as Figure 4 The schematic diagram of another embodiment of the shown depolarizing mirror group of the present invention, this embodiment is similar to the embodiment shown in Figure 2, in this embodiment, the light incident angle is θ 1 is 45°. After the incident light 5 enters the polarizing reflector 1 set at 45° between the normal line 6 and the horizontal plane in the vertical downward direction, the reflected light becomes incident on the compensating reflector 2 in the horizontal direction, and the compensating reflector 2 is perpendicular to the horizontal plane, and the compensation reflector The projection of the normal 8 of the mirror and the normal 6 of the polarizing mirror on the horizontal plane forms an angle of 45°, and the reflected light of the compensating mirror 2 and the reflected light of the polarizing mirror 1 are emitted in a horizontal direction at an angle of 90°. At this time, in order to meet the conditions of the depolarizing mirror ...

Embodiment 3

[0087] Such as Figure 5 The schematic diagram of the third embodiment of the depolarizing mirror assembly of the present invention is shown. The optical path of the depolarizing reflector of the present invention only includes one set of mirror groups, which consists of two polarizing reflectors 1 and 3 and one compensating reflector 2 . The reflected light of the first polarizing reflector 1 is the incident light of the second polarizing reflector 2 , and the light passing through the second polarizing reflector 2 is reflected into the compensating reflector 2 . The incident light 5 of the first polarizing reflector 1 and the first polarized incident plane formed by the normal line 6 are the same as the second polarized incident plane formed by the incident light 9 of the second polarized reflector 2 and the normal line 10. The incident plane is perpendicular to the compensating incident plane formed by the incident light 7 and the normal 8 of the first compensating mirror....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com