Vacuum fluorescent display device life-span prediction method

A technology for life prediction and display, which is used in optical instrument testing, machine/structural component testing, instruments, etc., to save life test time and reduce life prediction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Under the condition that the acceleration parameter β of the vacuum fluorescent display (VFD) has been determined, if the average life expectancy is predicted, it is only necessary to make a filament temperature stress of T (700℃≤T≤850℃, it is recommended that the filament temperature is close to the maximum temperature stress) Compared with the conventional VFD life test and accelerated life test, the accelerated life test can be used to predict its average life, which can shorten the test time and save the manpower, material and financial resources required for the test.

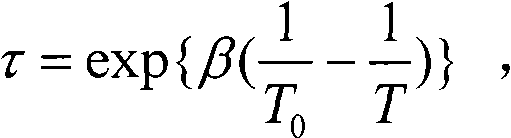

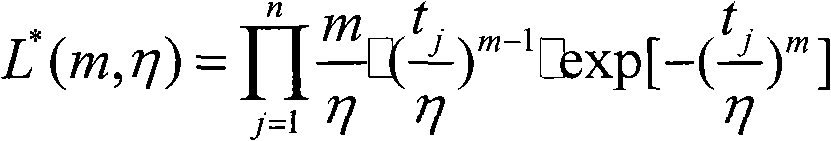

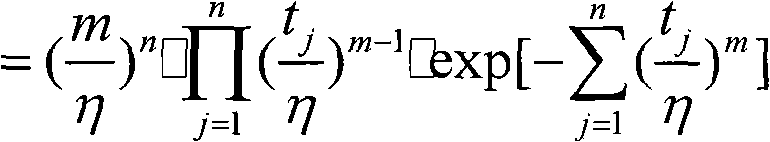

[0011] If there are n test sample tubes under a filament acceleration temperature stress T, the acceleration coefficient is:

[0012] τ = exp { β ( 1 T 0 - 1 T ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com