Life prediction method and system for rubber and plastic shaft seals based on finite element wear degradation analysis

A technology of life prediction and finite element, which is applied in design optimization/simulation, instrumentation, calculation, etc., can solve the problems of high cost and low accuracy, and achieve the goal of reducing prediction cost, improving accuracy, and saving manpower and material resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

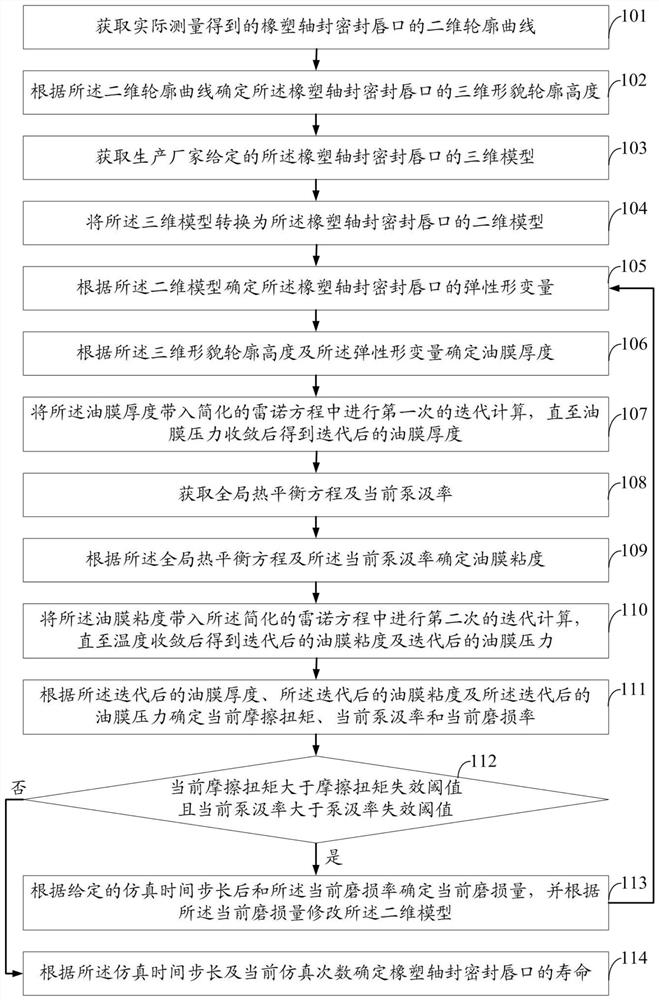

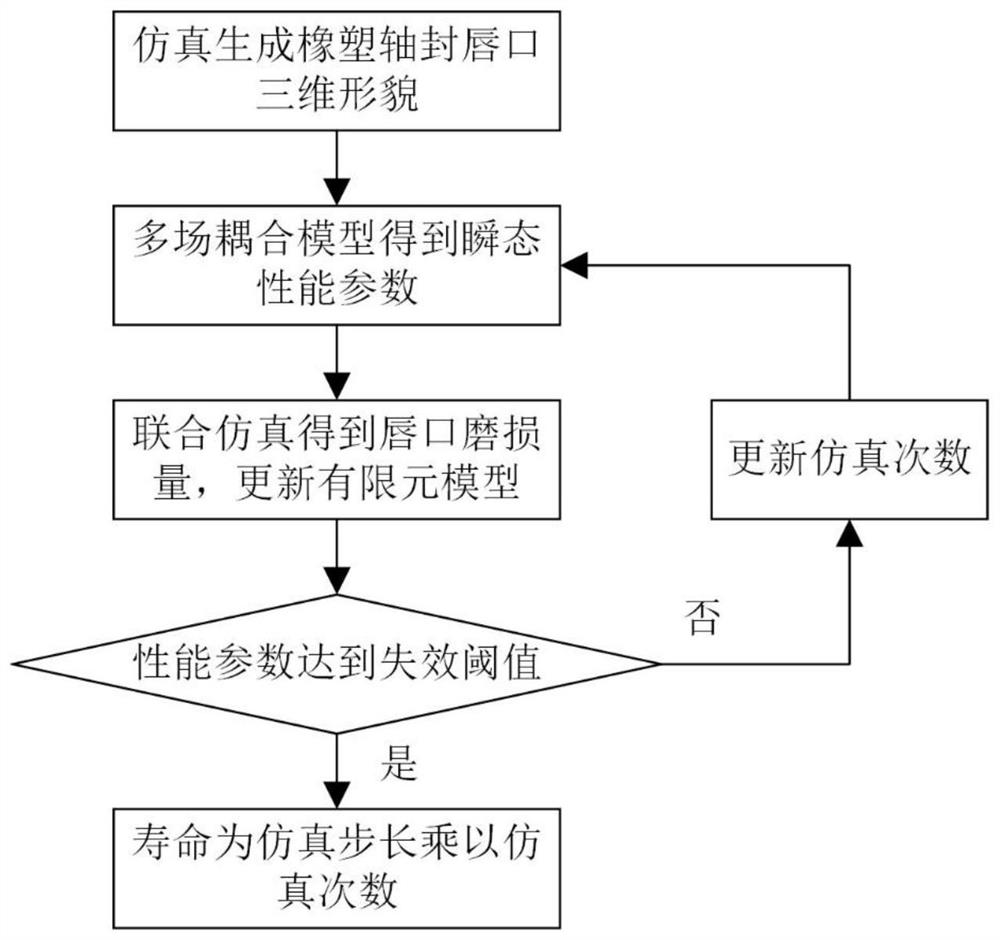

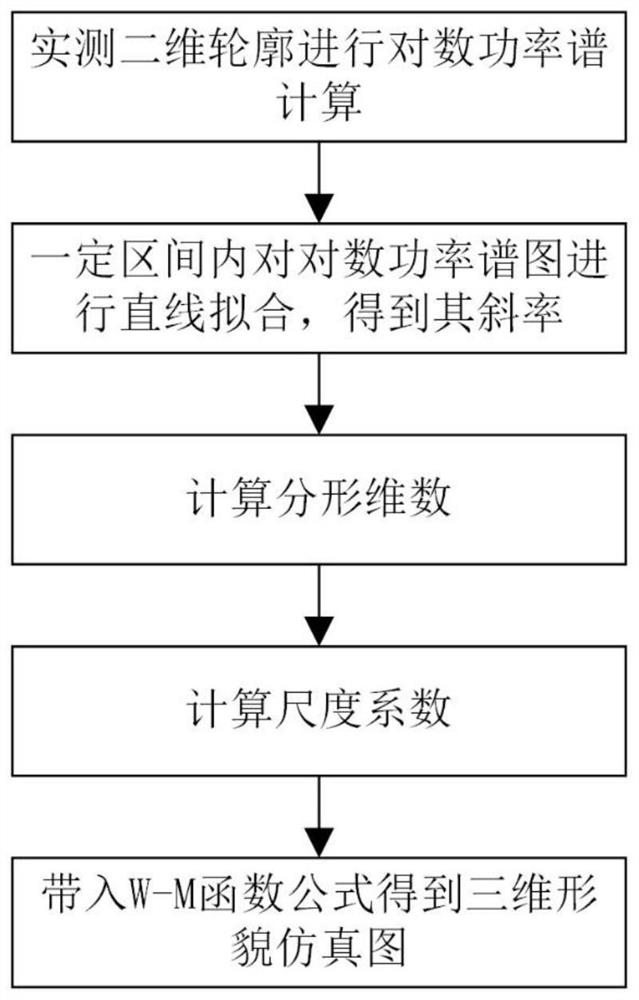

Method used

Image

Examples

Embodiment

[0184] In the embodiment of the present invention, a three-dimensional modeling of a certain type of rubber and plastic shaft seal is carried out, and the appearance of the three-dimensional model is as follows Figure 8 shown. At the same time, the two-dimensional profile of the actual surface was measured by a roughness profiler. The two-dimensional profile curve is as follows: Figure 9 As shown, the abscissa is the axial sampling length, and the ordinate is the height of the two-dimensional profile. And based on previous tests and expert experience, the relevant failure thresholds of friction torque and pumping rate under specific working conditions were obtained. The working conditions and failure thresholds are shown in Table 1:

[0185] Table 1 Test profile and failure threshold under this profile

[0186]

[0187]

[0188] According to the method of the present invention, the simulation time step is set to be 1 hour, and finally the degradation curve of its pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com