Capacitive load driving circuit, capacitive load driving method, and driving circuit for liquid crystal display device

A capacitive load and drive circuit technology, applied to static indicators, instruments, etc., can solve problems such as charge pump failure, achieve the effects of saving power consumption, improving drive characteristics, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

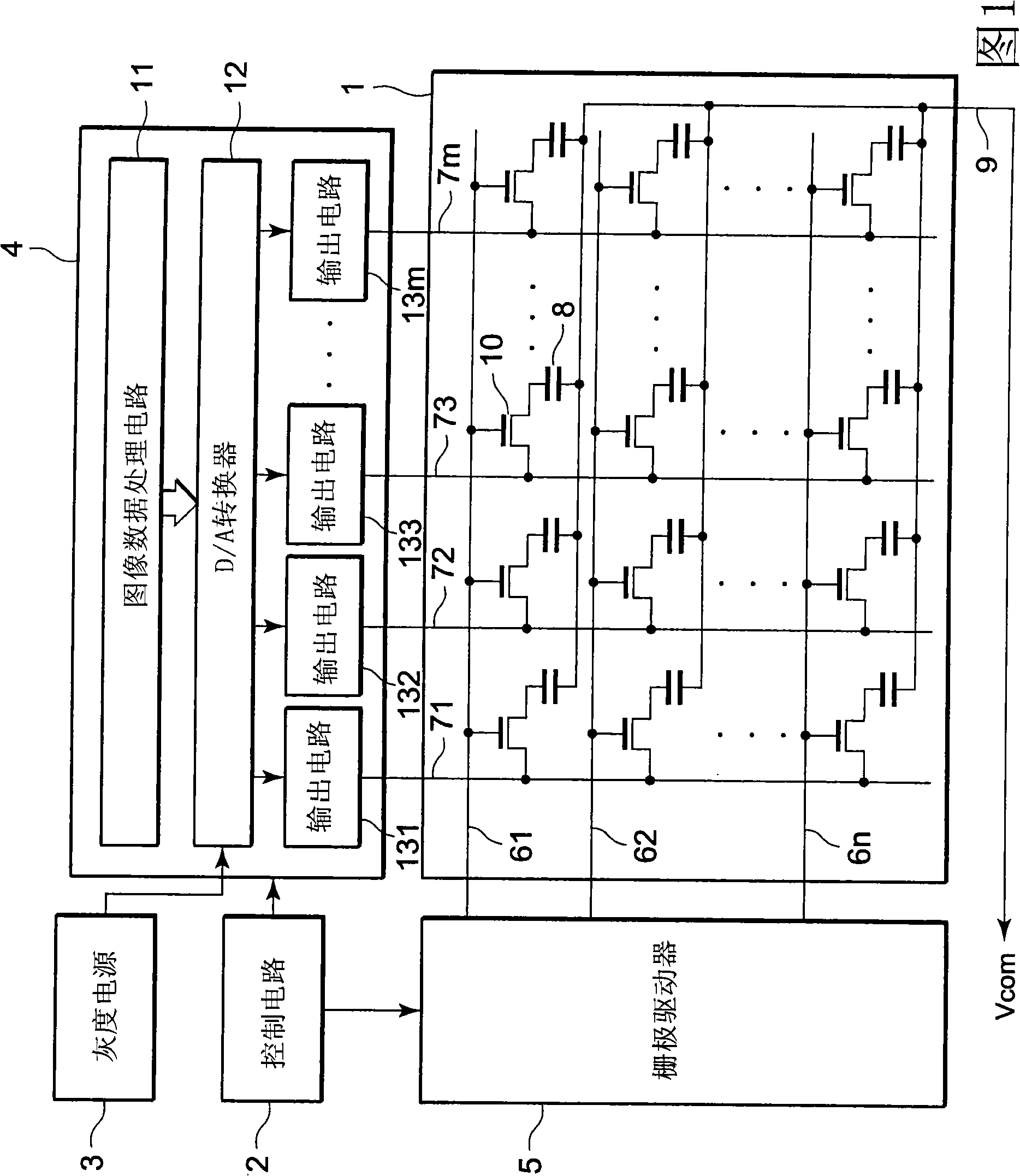

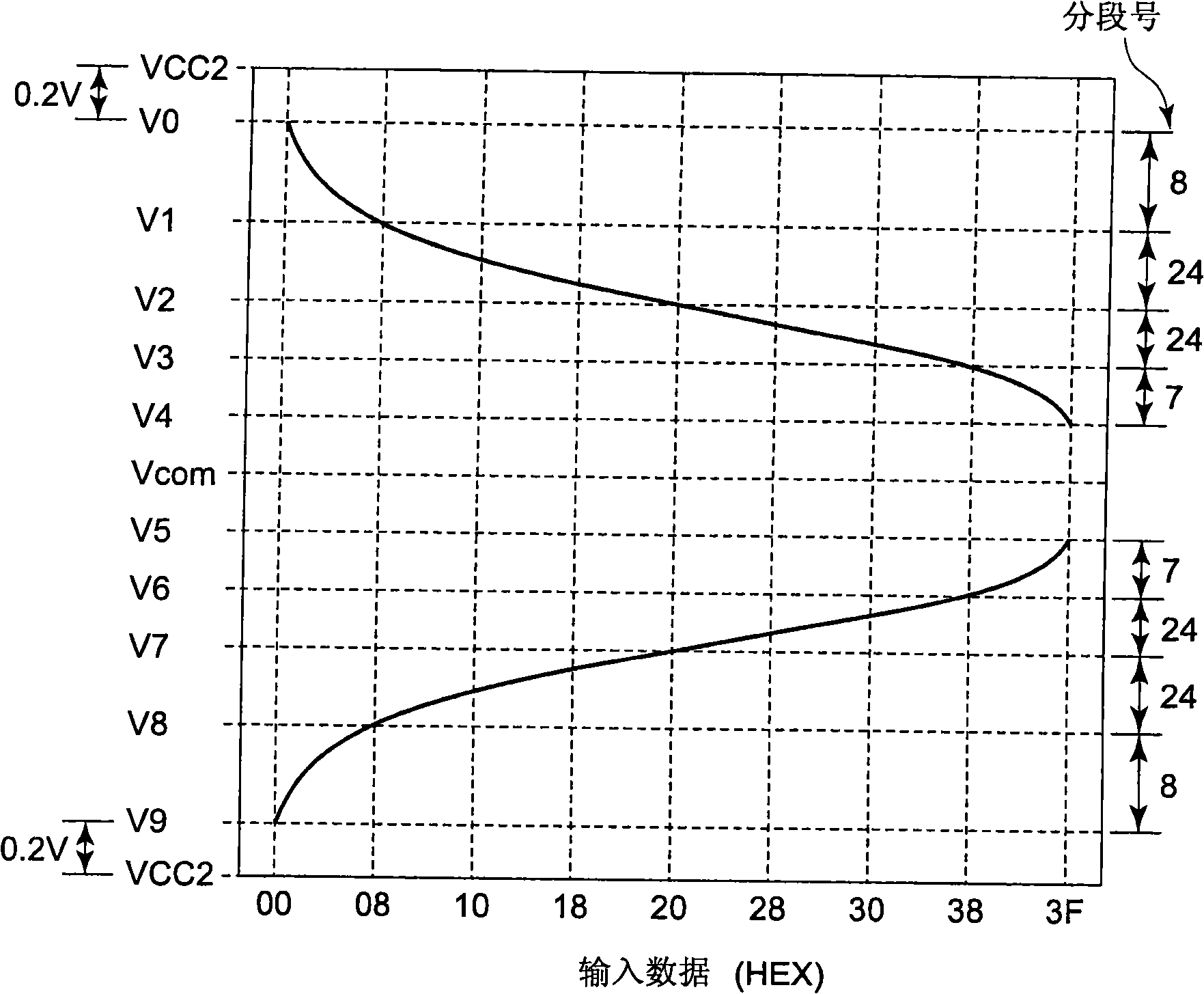

[0052] FIG. 1 is a block diagram showing the configuration of a liquid crystal display device according to a first embodiment of the present invention. The configuration of this liquid crystal display device is the same as that of the liquid crystal display device described in the section describing the prior art, but will be described again below. The liquid crystal display device according to the first embodiment has a system for applying an analog image data signal generated based on digital image data to a liquid crystal panel. The liquid crystal display device includes a liquid crystal panel 1 , a control circuit 2 , a grayscale power supply circuit 3 , a data electrode drive circuit (source driver) 4 and a scan electrode drive circuit (gate driver) 5 .

[0053] The liquid crystal display panel has an active matrix driving system using thin film transistors (TFTs) as switching elements. In the liquid crystal panel 1, the pixels are respectively composed of n (n is a natu...

no. 2 approach

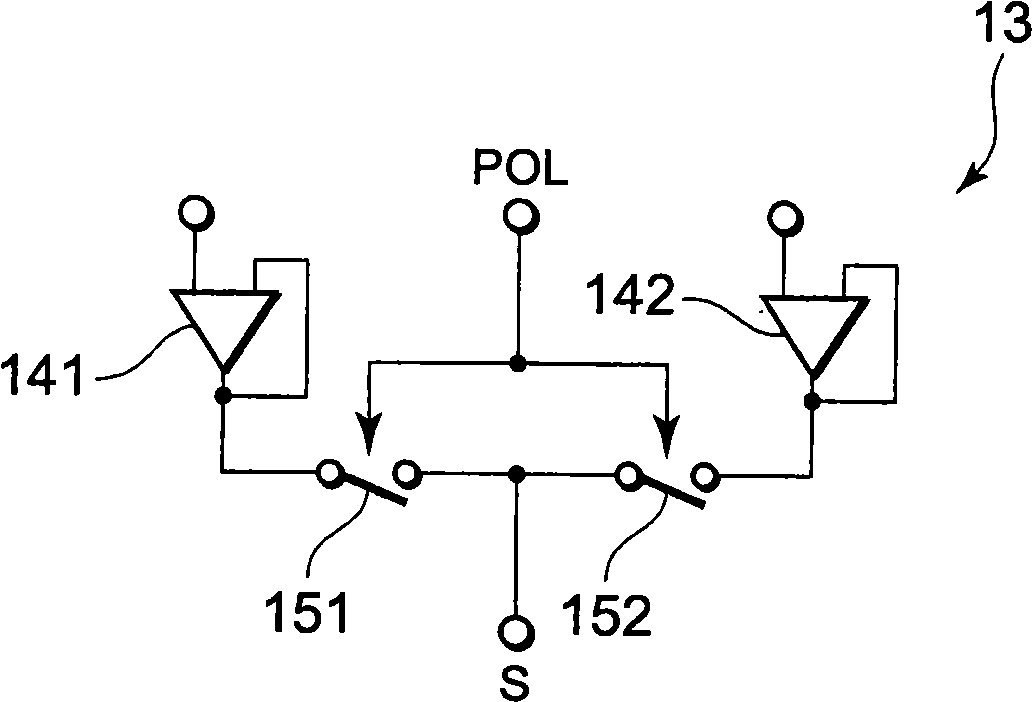

[0104] In the first embodiment as described above, the voltage used for the precharge of the arithmetic amplifier having the precharge (overdrive) function is determined as the positive power supply voltage (VDD) or the negative power supply voltage (VSS), and by changing the precharge Charging time is optimized for this drive. In the second embodiment, the precharge time is constant, and the driving is optimized by varying the precharge voltage (ie, a voltage different from the desired voltage). Since the difference from the first embodiment is only the output circuit 13, description of the liquid crystal display device as a whole will be omitted below.

[0105] Figure 17 One circuit of each of the digital-to-analog converter 12 and the output circuit 13 of the source driver 4 is shown. The output circuit 13 includes a most significant bit determination circuit 27 , a switch control circuit 30 , a precharge voltage control circuit 31 and an LCD drive amplifier circuit 60 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com