Last stage movable vane of air cooling steam turbine

A technology for steam turbines and moving blades, which is applied to machines/engines, supporting components of blades, mechanical equipment, etc., and can solve problems such as backward structure, poor unit economy, and high dynamic stress of blades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

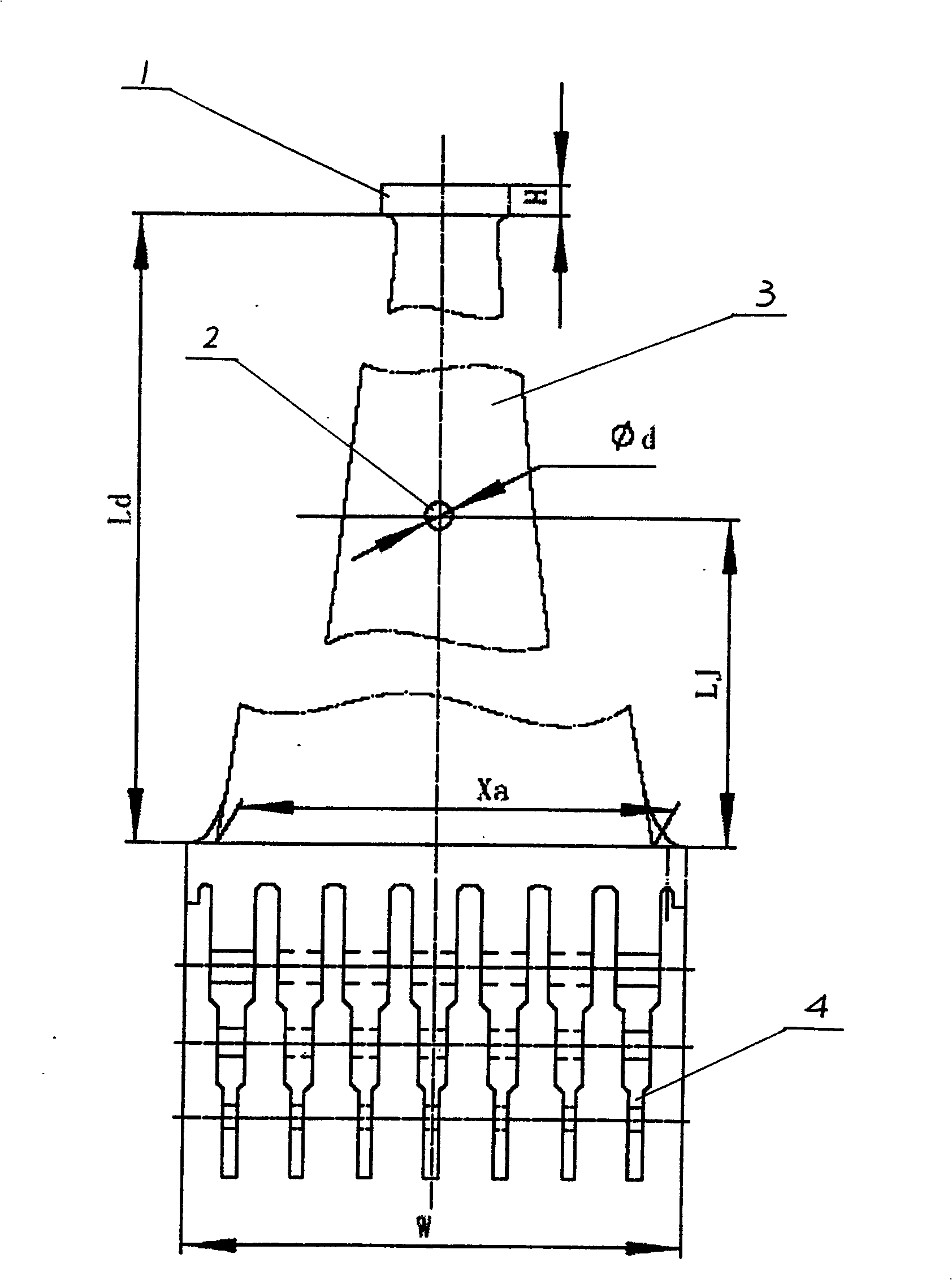

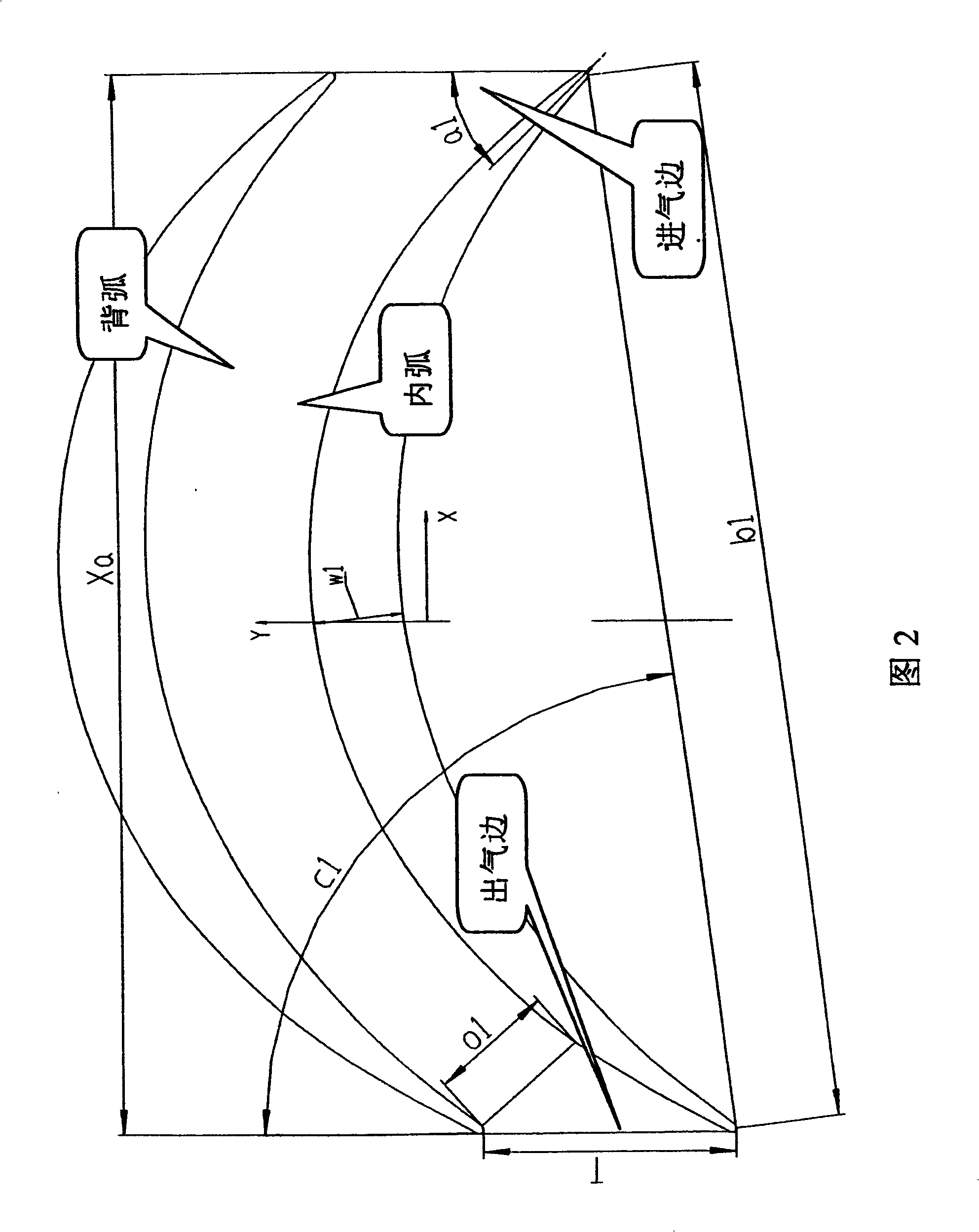

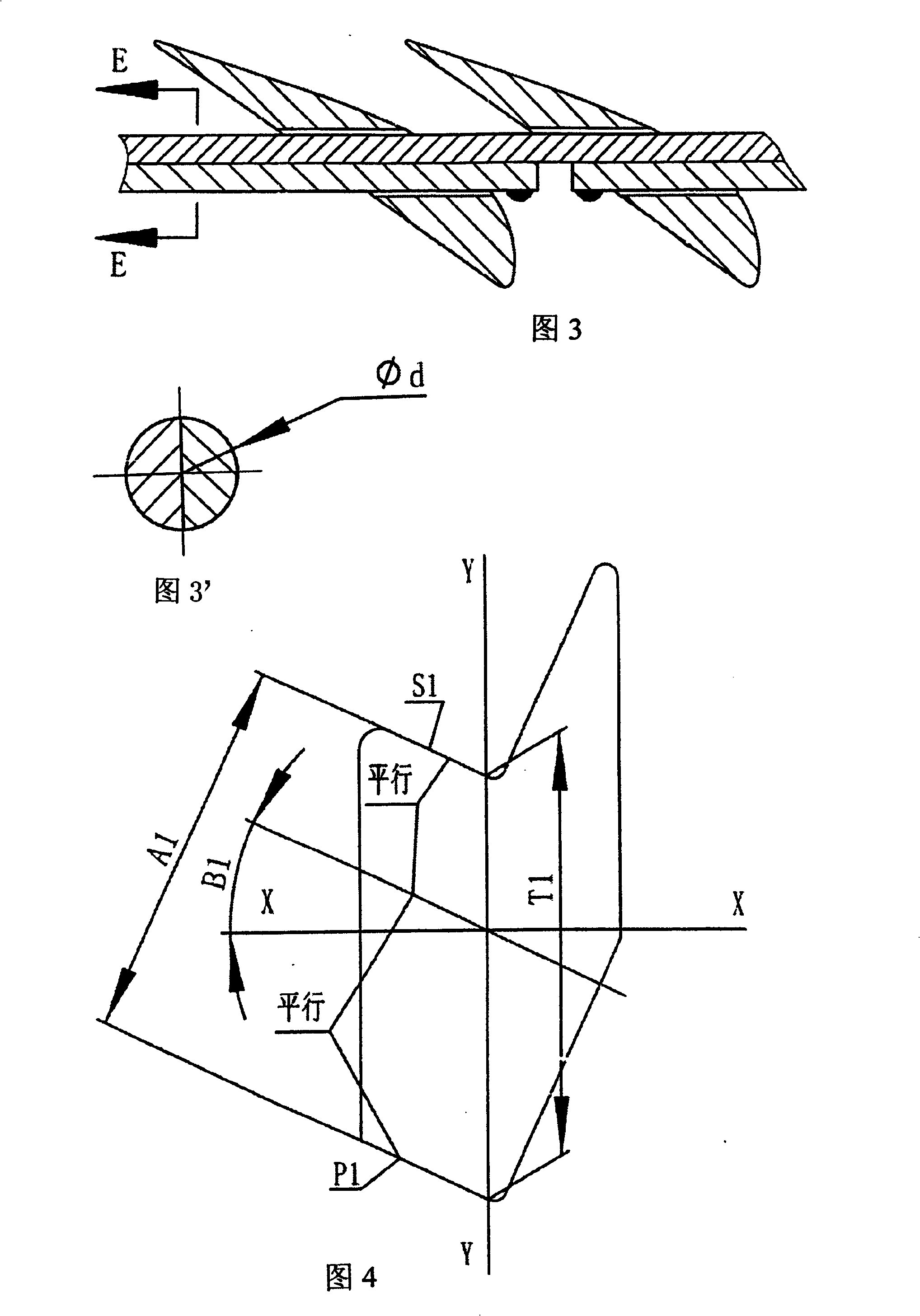

[0022] see figure 1 , Figure 2, Figure 4: Using suitable alloy steel blades and rotor materials, the moving blade manufactured according to the design drawing of this patent is composed of 4 parts, namely: shroud body 1, damping and tendon holes 2, blade body 3, Leaf root 4. All parts are integrally manufactured with the same high-strength alloy steel. The blades are installed in the impeller grooves on the outer circle of the rotating shaft through the 7 fork blade roots 4, and 94 blades are installed in each round of the grooves. When the blades are installed in the impeller grooves of the last week of the impeller, the final stage of the high-power steam turbine is formed. . For a 600MW air-cooled steam turbine, each unit needs four positive and negative stages (4 exhaust ports), and for a 300MW air-cooled steam turbine, each unit requires a total of two positive and negative stages (2 exhaust ports). A steam turbine with a large exhaust area can meet the requirements of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com