Electric dust collector

A vacuum cleaner and electric technology, which is applied in the direction of vacuum cleaners, electrical components, electromechanical devices, etc., can solve the problems of inability to realize commutator motor protection in the early stage, high price of thermal fuses, and high cost of electric vacuum cleaners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described below with reference to the drawings for understanding of the present invention. In addition, the following embodiment is an example which actualized this invention, and is not a characteristic which limits the technical scope of this invention.

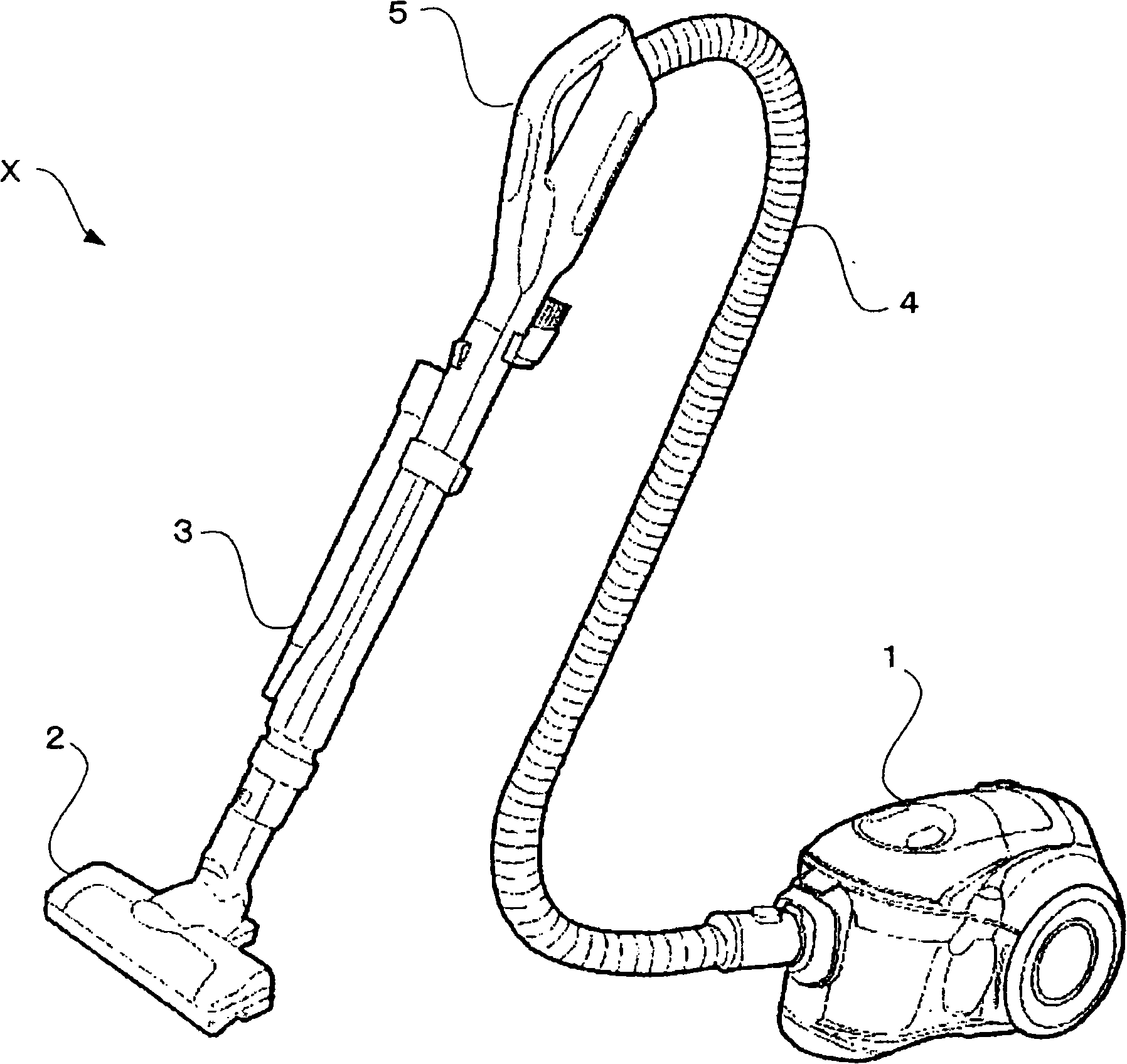

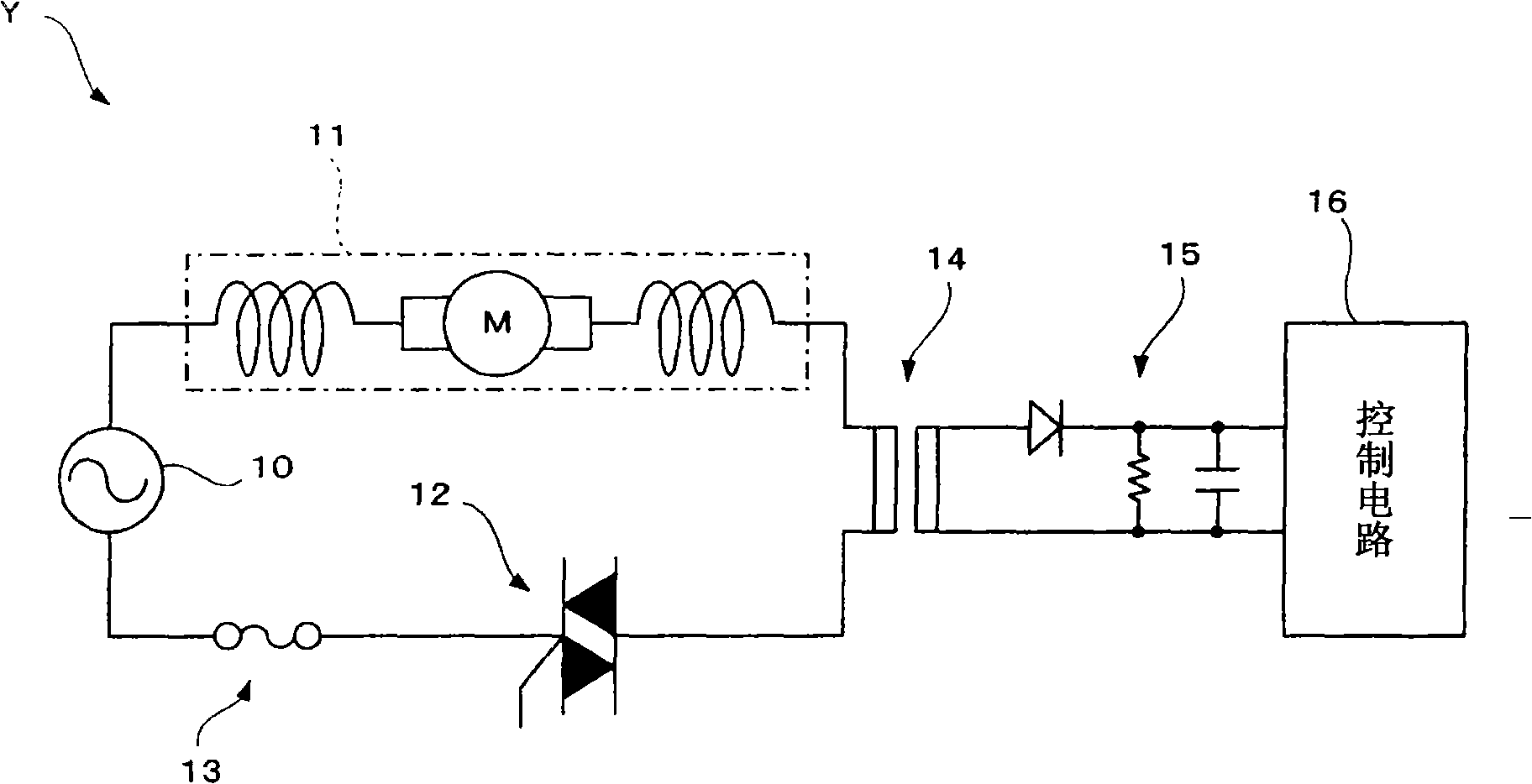

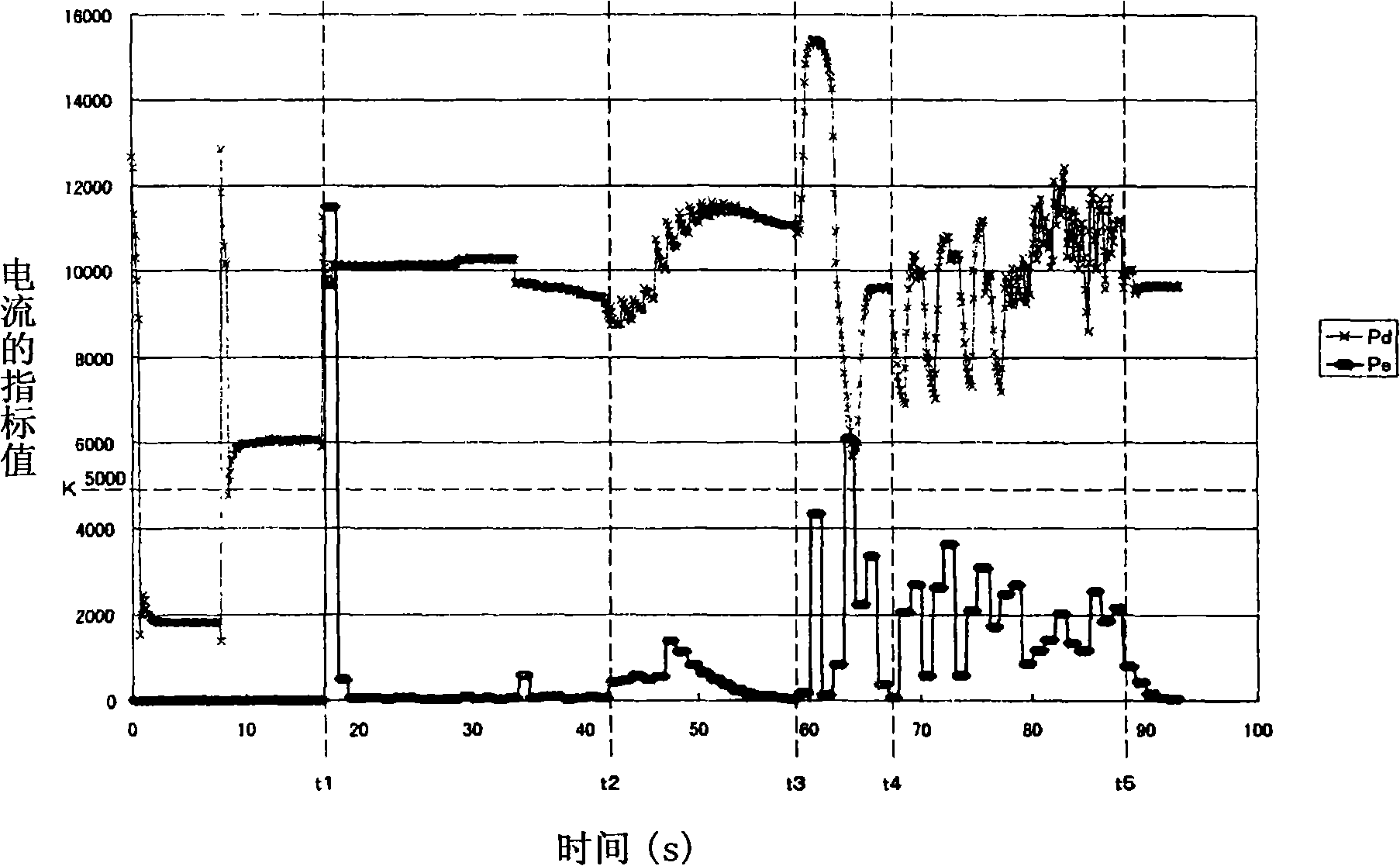

[0021] here, figure 1 It is an external view of an electric vacuum cleaner X according to an embodiment of the present invention, figure 2 It is a circuit diagram of a motor drive circuit Y to which a commutator motor 11 provided in an electric vacuum cleaner X according to an embodiment of the present invention is connected, image 3 and Figure 4 It is a figure which shows an example of the measurement result of the electric current value Pd of the commutator motor 11 in electric vacuum cleaner X concerning embodiment of this invention, and its change range Pe, Figure 5 It is a flowchart showing an example of the procedure of the abnormal spark prevention process ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com