Floor board edge sealing strip

A technology of edge banding and flooring, which is applied in the direction of floors, buildings, building structures, etc., can solve the problems of separate profiles of edge banding and keel, high installation cost and labor-intensive, etc., so as to save installation man-hours, easy processing, and save The effect of installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

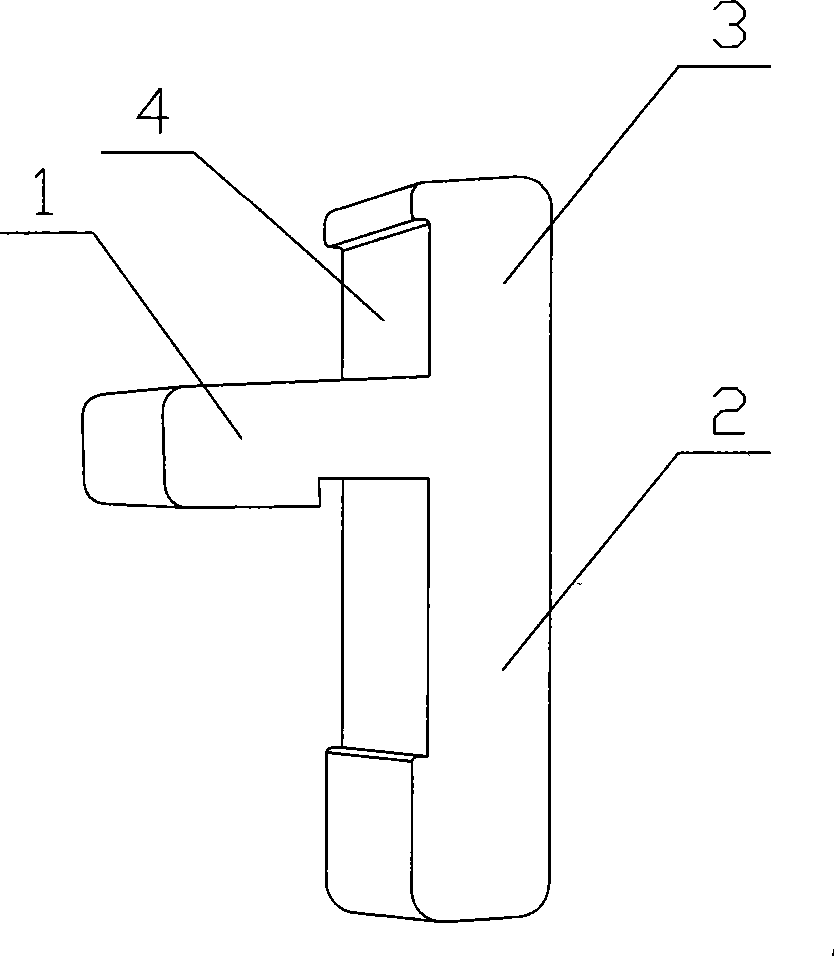

[0010] Such as figure 1 As shown, it is a floor edge banding strip according to the present invention, which includes horizontal edge banding 11 and vertical edge banding 2 which form corners with each other. The vertical edge banding 2 extends upwards to form an upper edge banding 3. Card slot 4, card slot 4 can clamp the floor, and the floor edge banding is " ” shape, the height of the upper edge band 3 is less than the height of the vertical edge band 2, the vertical edge band 2 of the edge band is supported on the ground, and the horizontal edge band 1 supports the floor, which is equivalent to the role of a keel, and the floor is supported on the horizontal The upper edge banding 1 and the upper edge banding 3 play the role of edge banding on the floor. The invention combines the keel and the edge banding strips into one, which not only saves installation cost but also saves installation man-hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com