Zoom lens system and image pickup device containing above system

一种变焦透镜、负透镜的技术,应用在电视系统的零部件、图像通信、彩色电视的零部件等方向,能够解决紧凑性高光学性能困难等问题,达到满意光学性能、实现光学性能的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-5

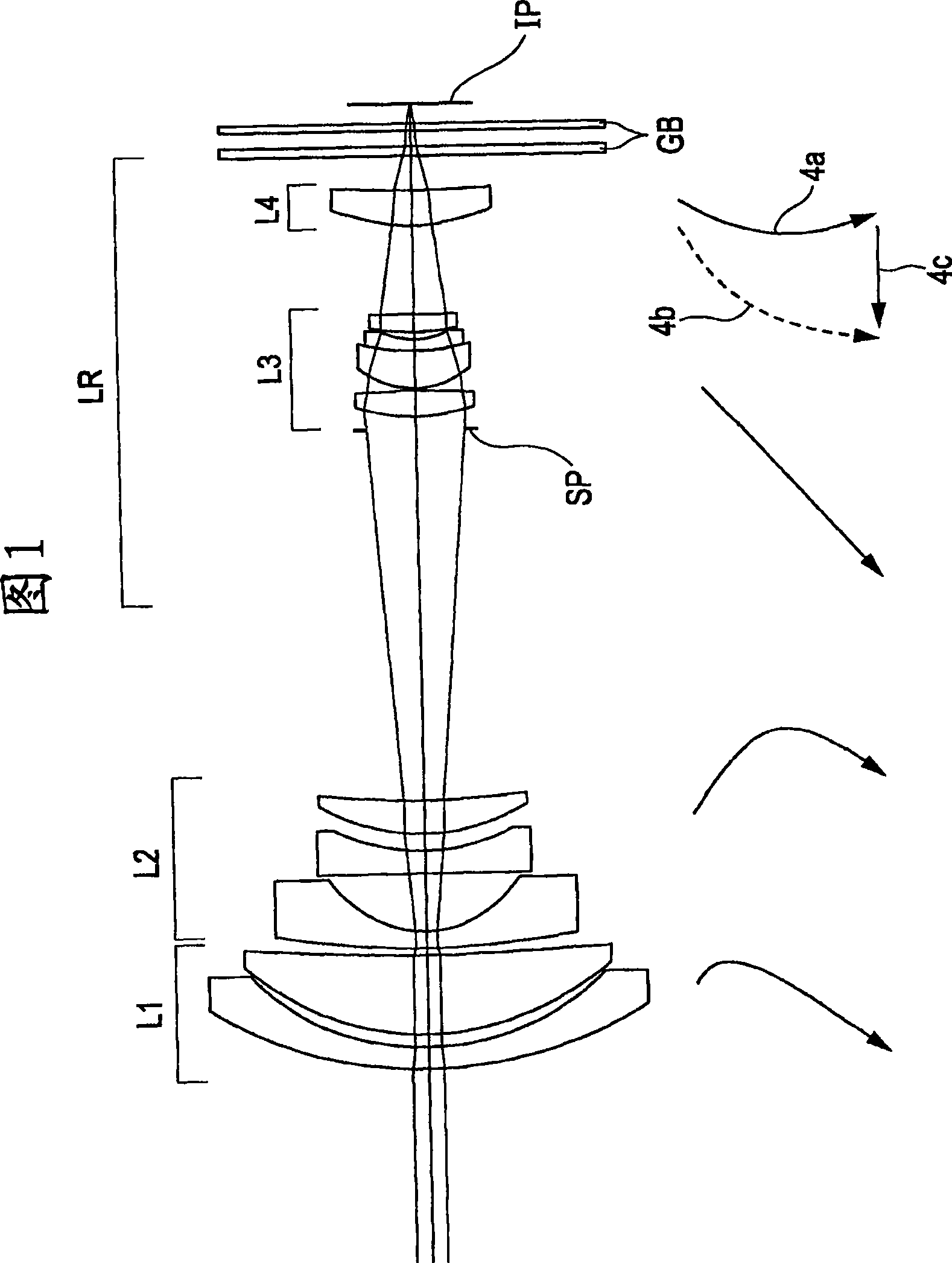

[0166] Numerical examples 1 to 5 corresponding to the first to fifth exemplary embodiments will be given below.

[0167] In each numerical example, i represents the order of lens surfaces counted from the object side, Ri represents the radius of curvature of the lens surface, Di represents the lens thickness and air gap between the i-th surface and the (i+1)-th surface, and Ni Represents the refractive index of the d-line, vi represents the Abbe number, and θgf represents the partial dispersion ratio.

[0168] The four surfaces closest to the image side correspond to, for example, an optical block GB or a color synthesis prism.

[0169] Denote the focal length, f-number, and half angle of view as f, FNO, and ω, respectively.

[0170] Denote the aspheric coefficients as k, A, B, C, D and E.

[0171] When the displacement of the surface vertex at the height h from the optical axis in the direction of the optical axis is expressed as x, the shape of the aspheric surface is expr...

example 1

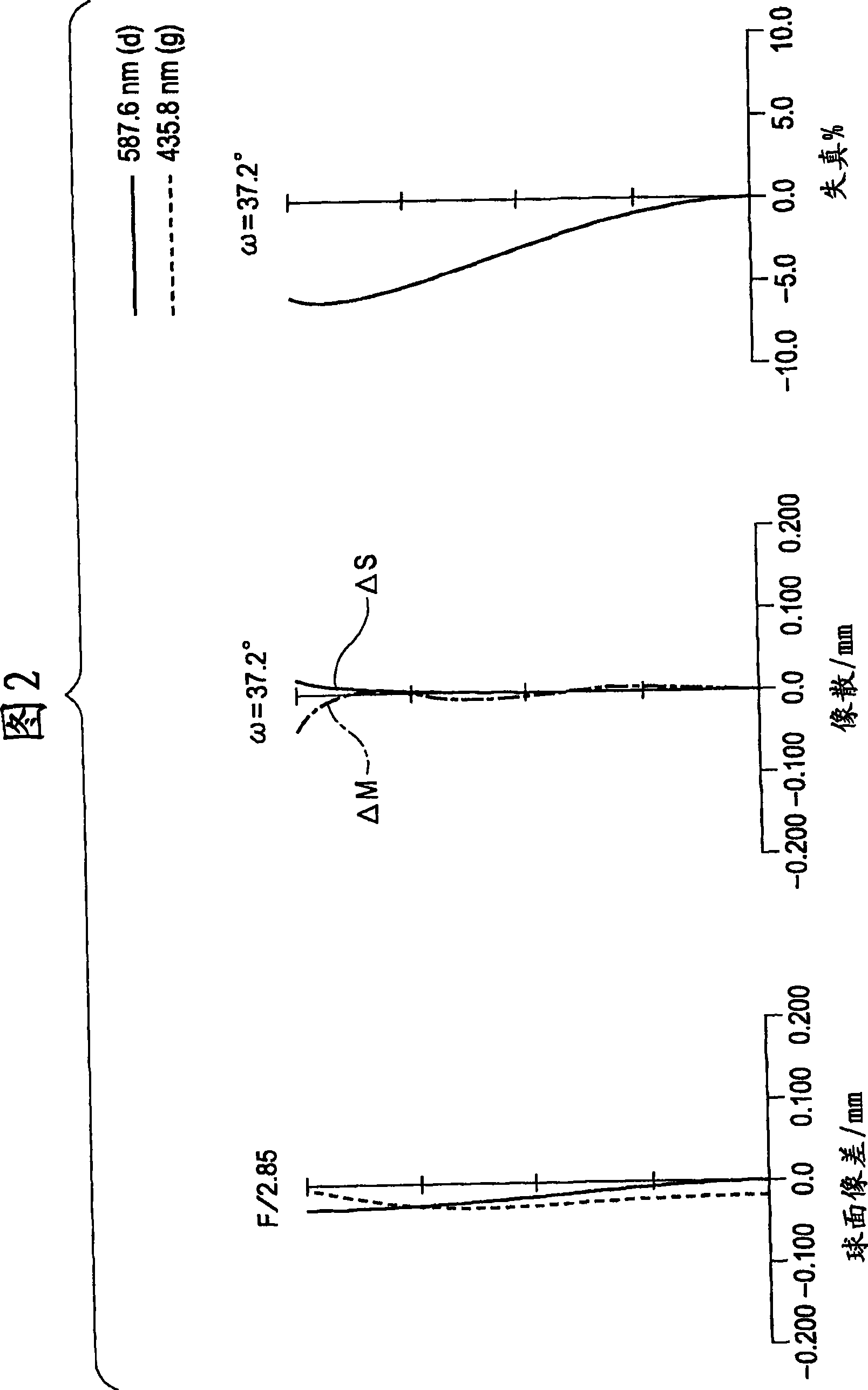

[0176] f: 4.8~46.0mm FNO: 2.85~5.87 ω: 37.21~4.52°

[0177] R D N v θgF

[0178] 1 24.037 1.20 1.847 23.8

[0179] 2 14.388 0.80 1.633 23.0 0.6747

[0180] 3 15.748 4.60 1.772 49.6

[0181] 4 151.929 (variable)

[0182] 5 52.003 0.95 1.883 40.8

[0183] 6 6.627 3.28

[0184] 7 (Aspherical) 1.35 1.860 40.3

[0185] 8 12.158 0.99

[0186] 9 12.279 1.91 1.923 18.9

[0187] 10 49.360 (variable)

[0188] 11 (aspherical) 1.50 1.678 55.3

[0189] 12 -80.221 0.10

[0190] 13 4.838 2.19 1.487 70.2

[0191] 14 12.070 0.60 2.003 28.3

[0192] 15 4.221 0.40

[0193] 16 16.466 1.18 1.487 70.2

[0194] 17 -34.172 (variable)

[0195] 18 (aspherical) 2.00 1.487 70.2

[0196] 19 36.606 (variable)

[0197] 20 inf. 0.60 1.516 64.1

[0198] 21 inf. 0.90

[0199] 22 inf. 0.40 1.516 64.1

[0200] 23 inf.

[0201] interval data

[0202] W T

[0203] d4 0.40 17.57

[0204] d10 21.91 2.41

[0205] d17 4.96 22.39

[0206] d19 1.98 1.26

[0207] Aspheric ...

example 2

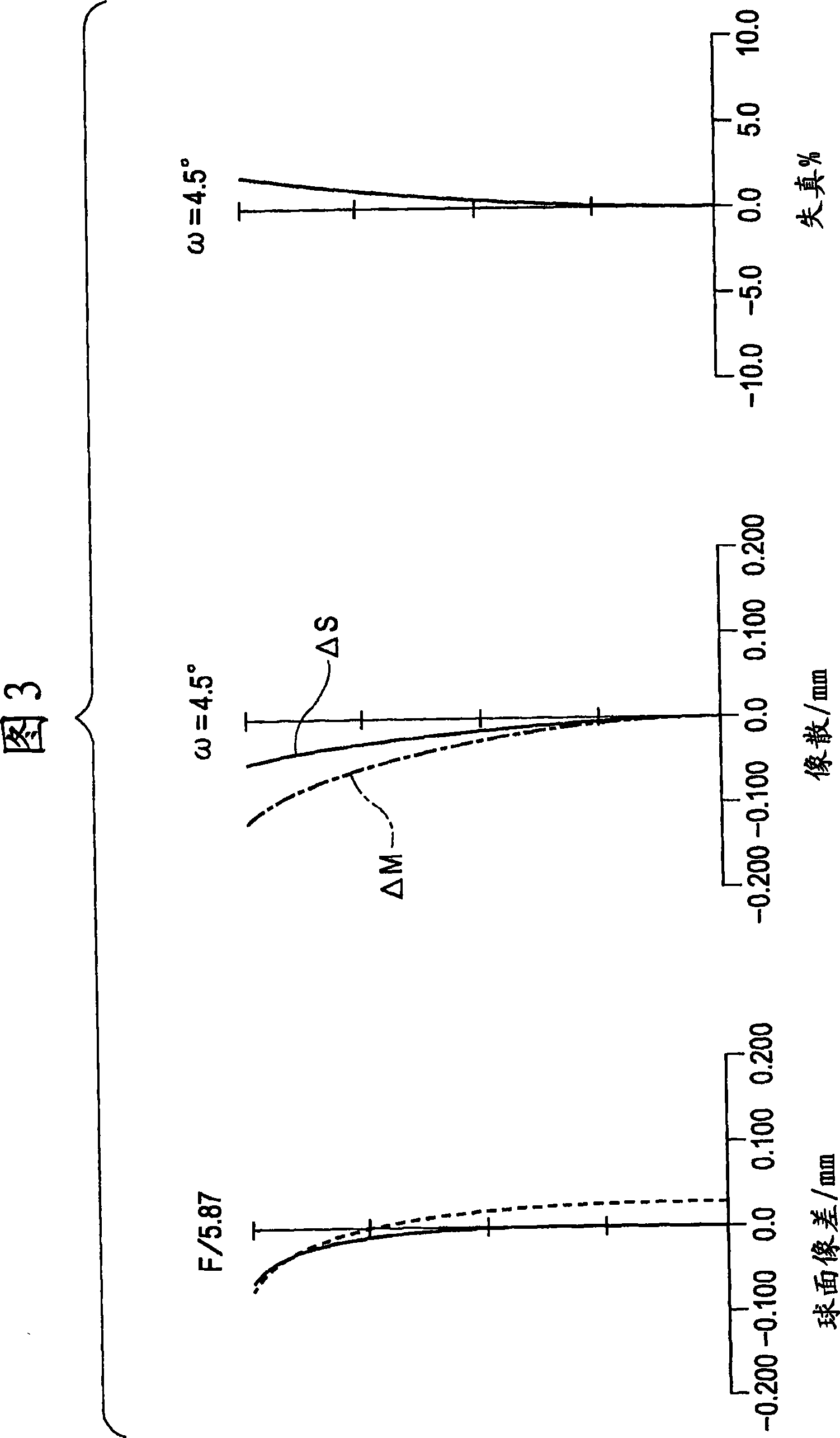

[0215] f: 4.7~31.6mm FNO: 2.88~5.67 ω: 37.17~6.44°

[0216] R D N v θgF

[0217] 1 (aspherical) 0.50 1.633 23.0 0.6747

[0218] 2 26.434 4.67 1.678 55.3

[0219] 3 -79.835 1.00 1.847 23.8

[0220] 4 332.271 (variable)

[0221] 5 44.219 1.00 1.772 49.6

[0222] 6 6.788 2.87

[0223] 7 (Aspherical) 1.40 1.860 40.3

[0224] 8 9.980 1.38

[0225] 9 11.273 1.81 1.923 18.9

[0226] 10 30.555 (variable)

[0227] 11 (aspherical) 1.50 1.589 61.1

[0228] 12 -24.353 0.10

[0229] 13 4.734 1.90 1.589 61.1

[0230] 14 13.243 0.60 2.003 28.3

[0231] 15 4.119 0.71

[0232] 16 -65.346 1.15 1.487 70.2

[0233] 17 -13.219 (variable)

[0234] 18 11.706 2.36 1.516 64.1

[0235] 19 -718.292 (variable)

[0236] 20 inf. 0.60 1.516 64.1

[0237] 21 inf. 0.90

[0238] 22 inf. 0.40 1.516 64.1

[0239] 23 inf.

[0240] interval data

[0241] W T

[0242] d4 0.48 12.66

[0243] d10 19.50 2.41

[0244] d17 4.44 24.55

[0245] d19 1.90 3.23

[0246] Aspheric Shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com