Testing method for badness of LCD critical point

A technology of liquid crystal display and testing method, which is applied in the directions of instruments, measuring electricity, measuring devices, etc., can solve the problems of poor deflection of liquid crystal molecules, poor electrical characteristics of thin film transistors, and difficult processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

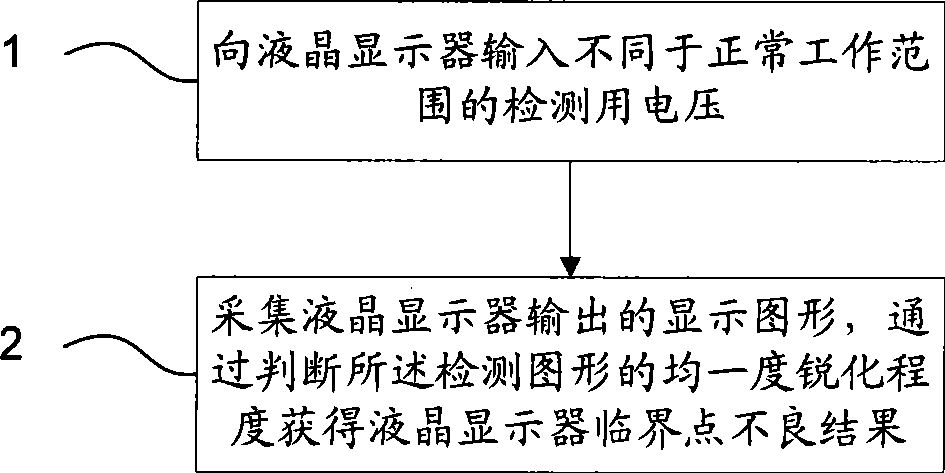

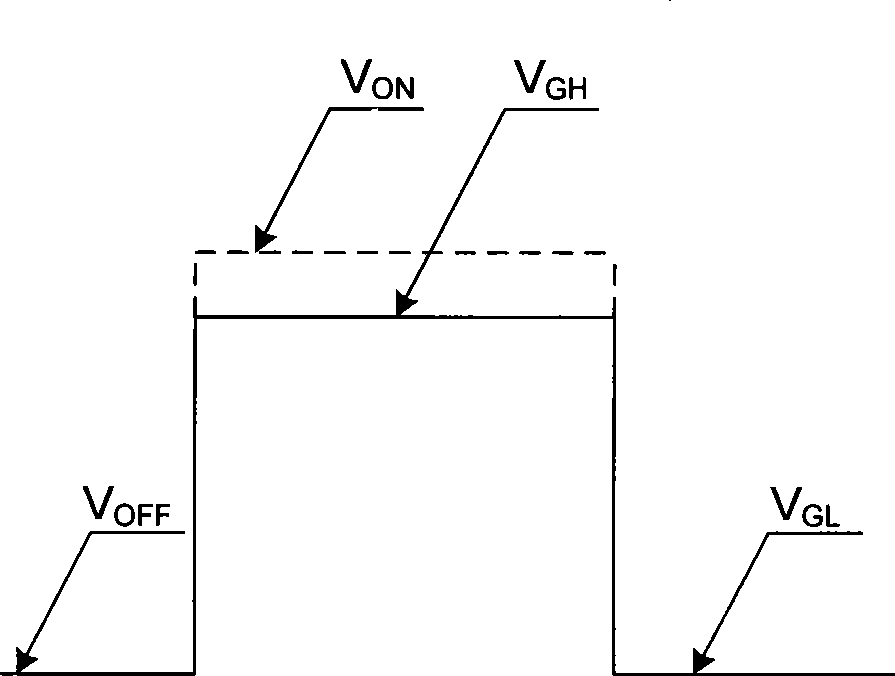

[0023] figure 2 It is a schematic diagram of the first embodiment of the present invention. The liquid crystal display critical point bad test method of this embodiment is specifically: to the liquid crystal display input detection grid forward open voltage V GH and sense the gate negative turn-off voltage V GL , where the detection gate forward turn-on voltage V GH Compared with the working gate positive full turn-on voltage V ON 20% to 50% lower, the gate negative turn-off voltage V for detection GL Equal to the full negative turn-off voltage of the working gate V OFF ; Gather the display graphics output by the liquid crystal display, and obtain the bad result of the critical point of the liquid crystal display by judging the uniformity sharpening degree of the detection graphics.

[0024] Specifically, before the test of this embodiment, it is necessary to modify the printed circuit board (PCB) of the signal input source of the liquid crystal display panel, and cut of...

no. 2 example

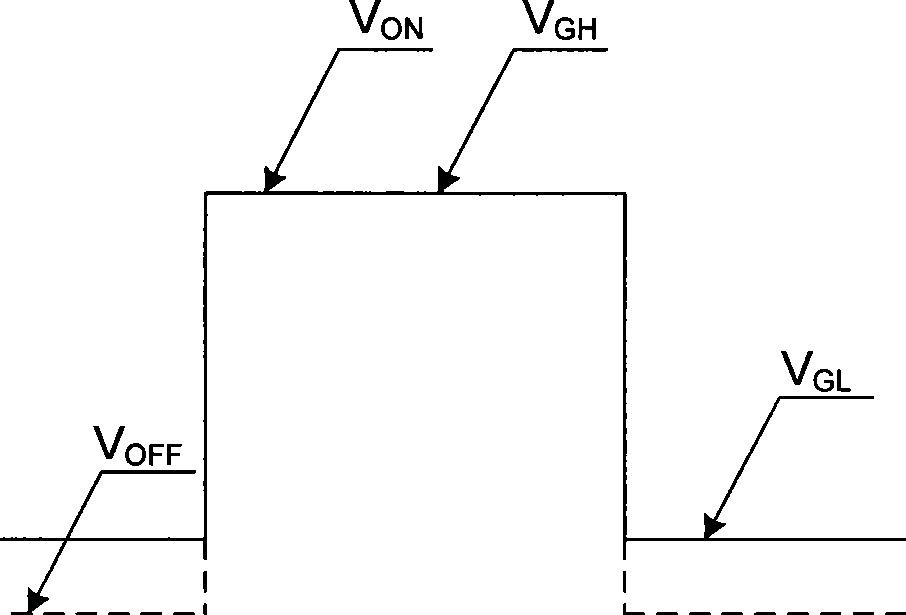

[0029] image 3 It is a schematic diagram of the second embodiment of the present invention. The liquid crystal display critical point bad test method of this embodiment is specifically: to the liquid crystal display input detection grid forward open voltage V GH and sense the gate negative turn-off voltage V GL , where the detection gate forward turn-on voltage V GH Equal to the working gate forward fully open voltage V ON , to detect the gate negative turn-off voltage V GL Compared with the working gate negative complete turn-off voltage V OFF 20% to 50% higher; collect the display graphics output by the liquid crystal display, and obtain the bad result of the critical point of the liquid crystal display by judging the uniformity sharpening degree of the detection graphics.

[0030] The specific process and working principle of the test in this embodiment are the same as those in the first embodiment. In this embodiment, the negative turn-off voltage V GL Compared with...

no. 3 example

[0033] Figure 4 It is a schematic diagram of the third embodiment of the present invention. The liquid crystal display critical point bad test method of this embodiment is specifically: to the liquid crystal display input detection grid forward open voltage V GH and sense the gate negative turn-off voltage V GL , where the detection gate forward turn-on voltage V CL Compared with the working gate positive full turn-on voltage V ON 20% to 50% lower, the gate negative turn-off voltage V for detection GL Compared with the working gate negative complete turn-off voltage V OFF 20% to 50% higher; collect the display graphics output by the liquid crystal display, and obtain the bad result of the critical point of the liquid crystal display by judging the uniformity sharpening degree of the detection graphics.

[0034] The specific testing process and working principle of this embodiment are the same as those of the first embodiment, and will not be repeated here. The gate forw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com