Fan frame fixing structure

A technology for fixing structures and fans, applied in the direction of support structure installation, circuit layout on support structures, elastic/clamping devices, etc., which can solve the problem of reduced ability to absorb vibrations, increased time to assemble or disassemble fan frames, elastic gaskets Easy to elastic fatigue and other problems, to achieve the effect of quick assembly and disassembly, and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

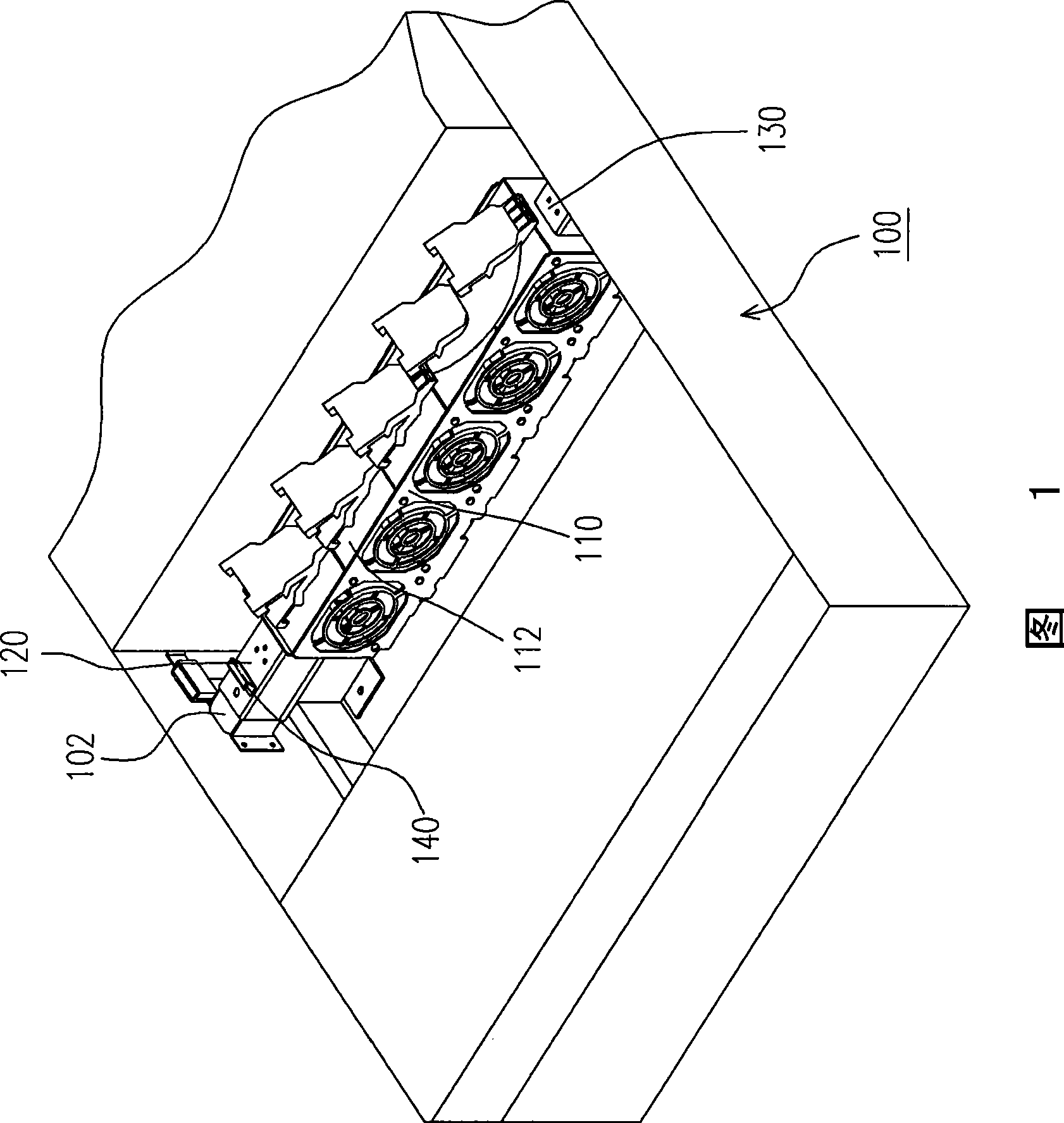

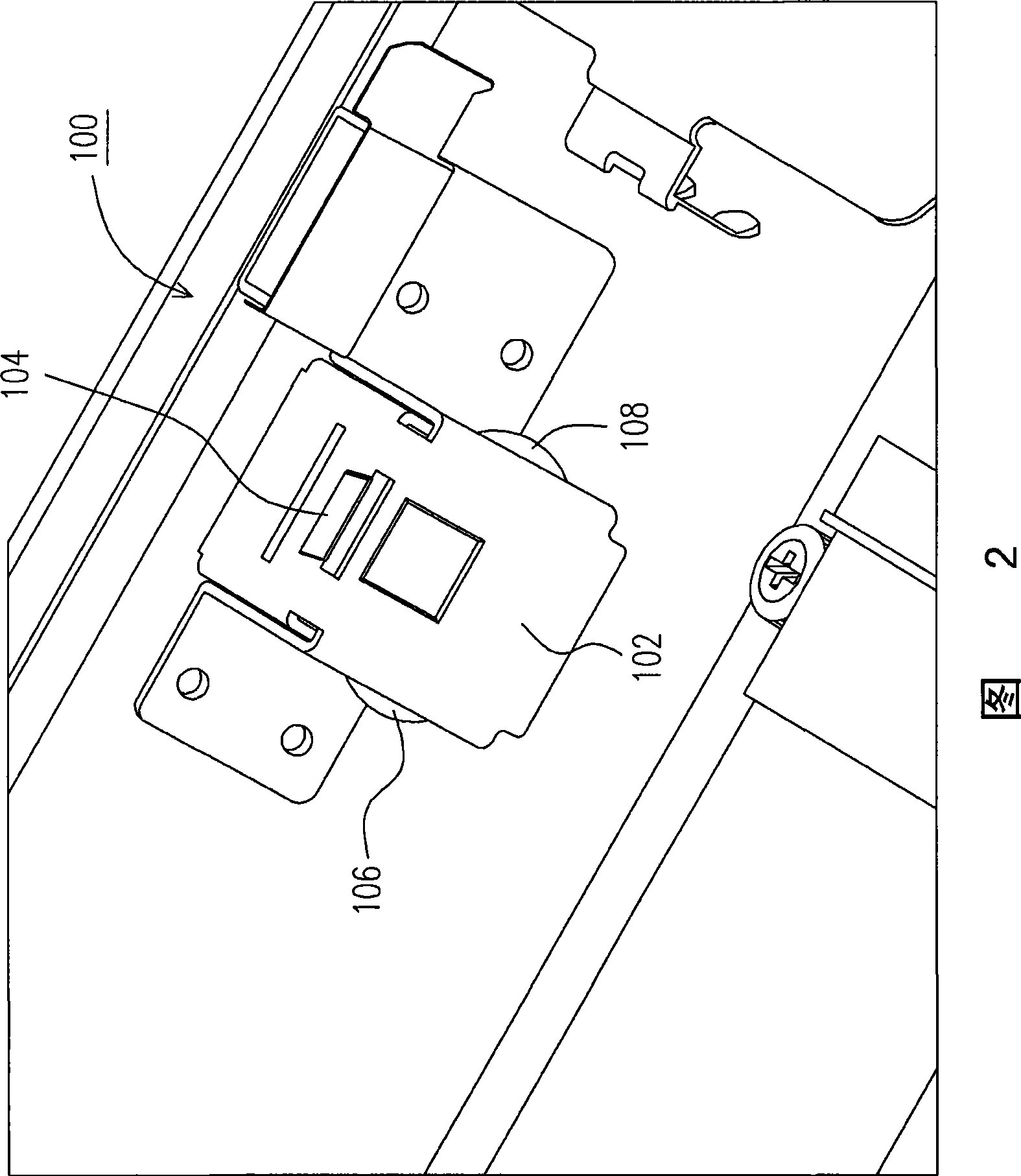

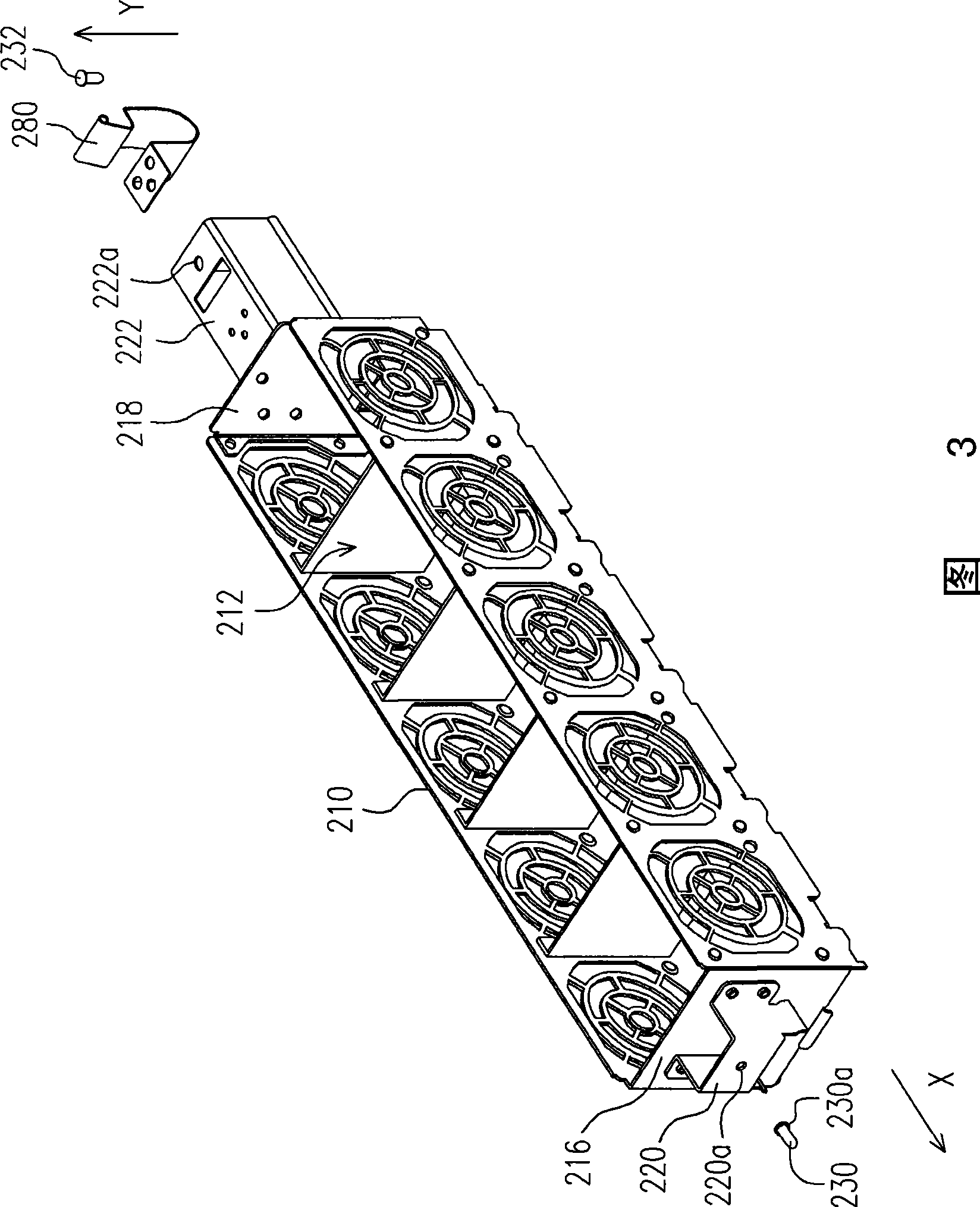

[0023] FIG. 3 is an exploded schematic diagram of a fan frame fixing structure according to an embodiment of the present invention. FIG. 4 is an exploded schematic view of the first fan seat and the first elastic washer on the casing, and FIG. 5 is a cross-sectional schematic view of the assembly of the fan frame fixing structure in FIG. 3 and the first fan seat in FIG. 4 .

[0024] Please refer to FIG. 3 first. The fan frame 210 has, for example, a plurality of accommodating spaces 212 for fixing a plurality of fans (not shown) in the fan frame 210, and the fans can provide a powerful cooling airflow to the inside of the server or the host. The heating element (not shown) dissipates heat. In this embodiment, the fan frame 210 has a fixed axis X and two sidewalls 216 , 218 , and the fans are arranged between the two sidewalls 216 , 218 of the fan frame 210 along the fixed axis. In addition, the fan frame 210 has, for example, two fixing frames 220 , 222 and two bolts 230 , 23...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap