Internal waverider hypersonic inlet and design method based on random shock form

A technology of hypersonic speed and design method, which is applied to the air inlet of turbine/propulsion device, combustion air/combustion-air treatment, engine components, etc. It can solve the problems of the shape restriction of the inlet and outlet of the inlet and improve the aerodynamic force of the outlet. performance, improving low Mach number starting performance, and reducing windward external resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

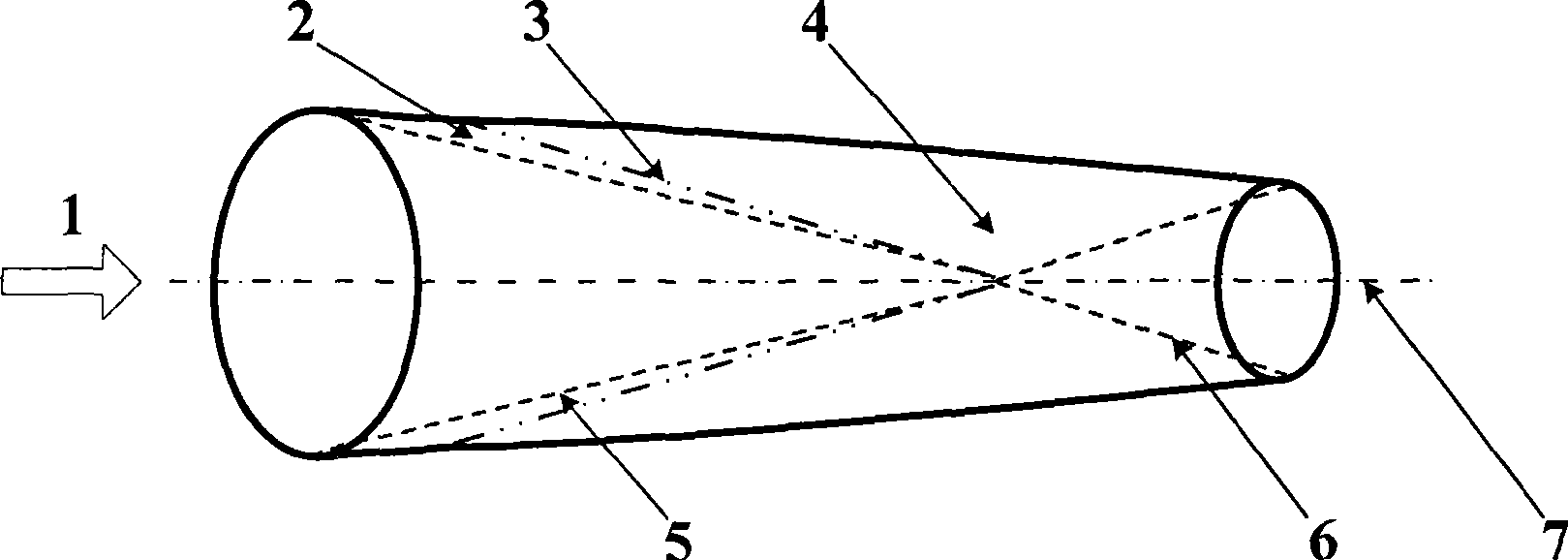

[0036] At the flow Mach number 6.0, the design is as follows figure 1 The axisymmetric internal contraction basic flow field is shown. The internal contraction rotary wall is composed of ICFA flow field and part of Busemann flow field. The flow field exit Mach number is designed to be 3.0, the area contraction ratio is 10.65, and the corresponding side length contraction ratio is 3.26.

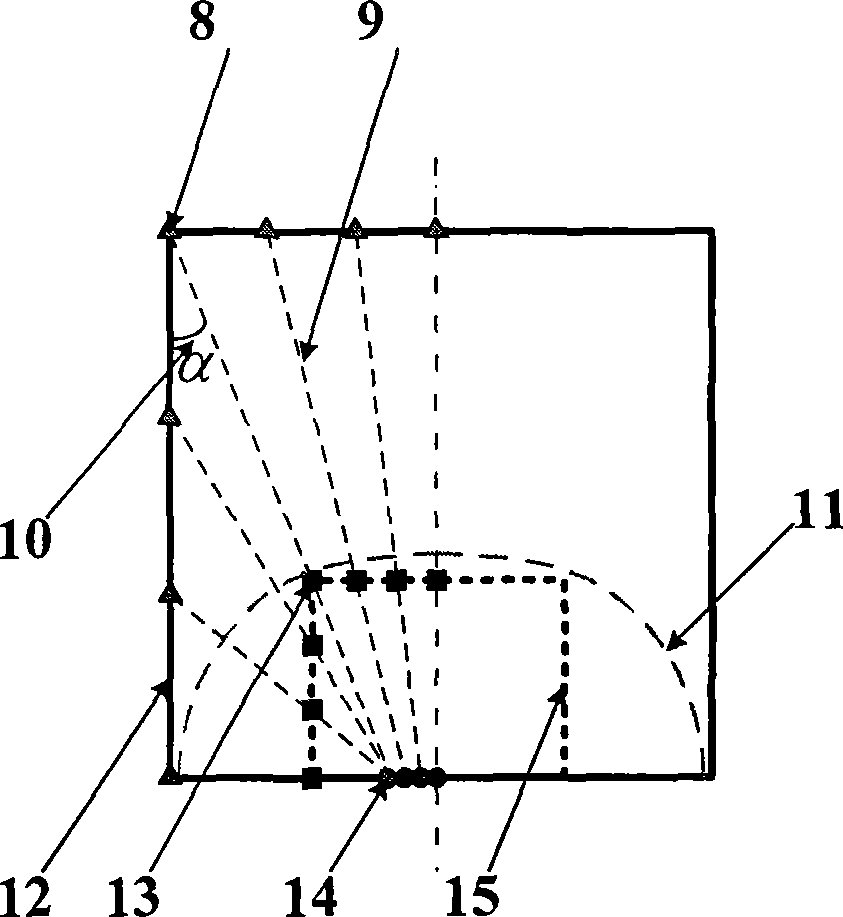

[0037] The design requirements for the shape of the air inlet are: the inlet of the air inlet is a square (such as figure 2 ), each center of curvature of the shock wave is located on the lower base of the square, and the two sides are required to shrink toward the same center of curvature, while the upper wall shrinks toward a series of centers of curvature evenly distributed in the direction of curvature. Therefore, the shape of the shock wave and even the shrinkage ratio of the intake port are uniquely determined by the shrinkage ratio control angle α. When the contraction ratio control a...

Embodiment 2

[0040] At the flow Mach number 6.0, the design is as follows figure 1 The axisymmetric internal contraction basic flow field is shown. The internal contraction rotary wall is composed of ICFA flow field and part of Busemann flow field. The flow field exit Mach number is designed to be 3.0, the area contraction ratio is 10.65, and the corresponding side length contraction ratio is 3.26.

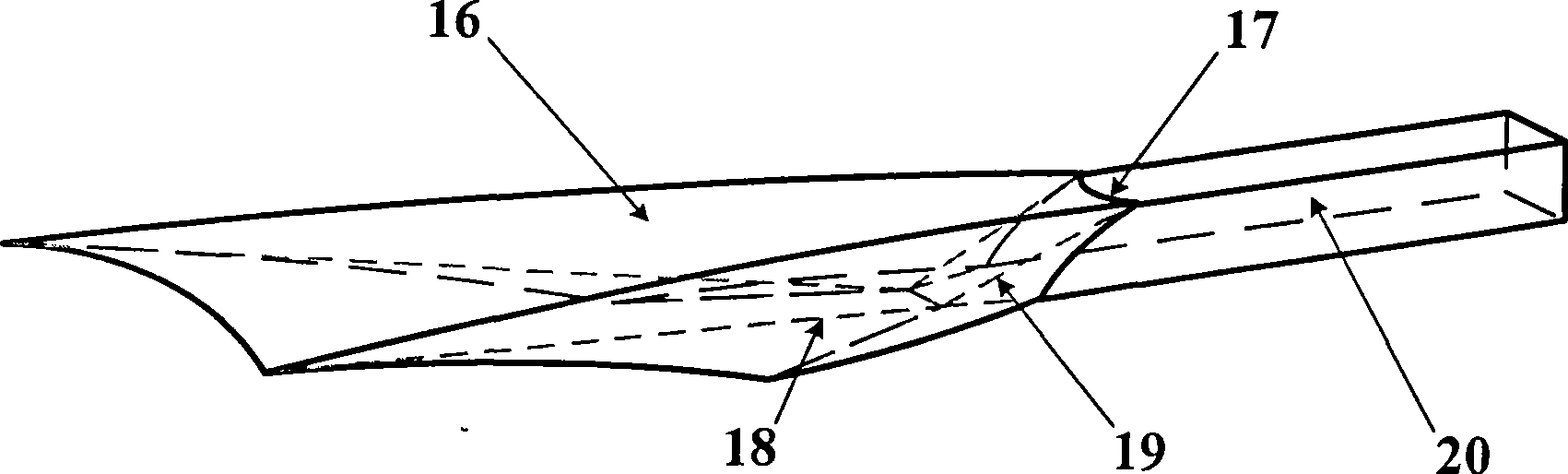

[0041] The design requirements for the shape of the air inlet are: the inlet of the air inlet is semicircular (such as Figure 4 ), each center of curvature of the shock wave is located on the outer circumference of the circle, requiring that the diameter of the semicircle shrinks toward the same center of curvature, while the circumferences on both sides shrink toward a series of centers of curvature evenly distributed in the direction of curvature. At this time, the shape of the shock wave and even the shrinkage ratio of the inlet port are controlled by the direction angle of the curvature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com