Automatic packaging production line for industrial explosive

A technology for automatic packaging and industrial explosives, applied in ammunition, ammunition storage, weapon accessories, etc., can solve the problems of unstable floor space, low production capacity, high price, etc., and achieve the effect of reliable performance, reasonable structure, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

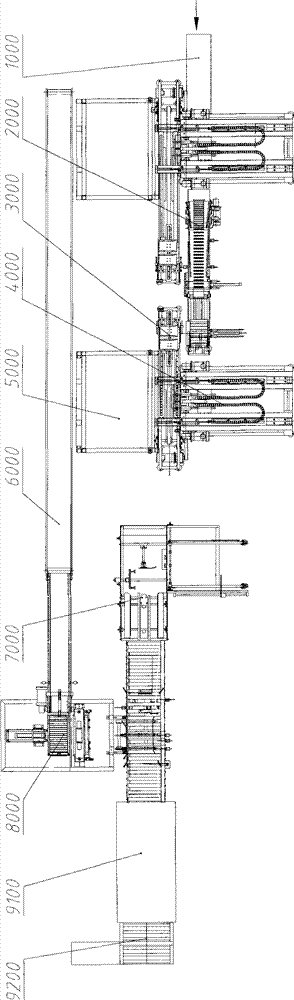

[0045] Such as Figure 1a and Figure 1b As shown, the present invention mainly consists of a medicine roll belt conveyor 1000, an automatic counting card loading device 2000, a track-type deck conveyor 3000 (one long and one short), a long push bag device 4000, a middle packaging bag sealing device 5000, and an intermediate chain plate Conveyor 6000, unpacking and bottom sealing machine 7000, side push type packing device 8000, folding cover and sealing device 9100, strapping device 9200, etc.

[0046] General technological process of the present invention sees Figure 10 .

[0047] 1. Introduction of stand-alone equipment structure:

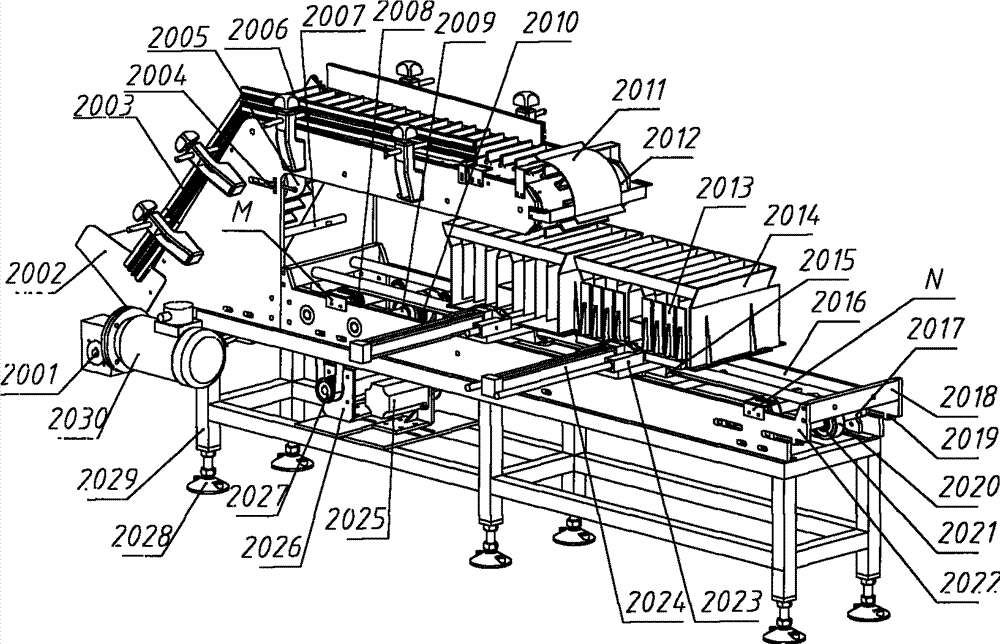

[0048] 1.1 as Figure 2a As shown, the automatic counting card loading device 2000, the explosion-proof motor 2030 is directly connected with the driving roller 2001 through the torque arm, the hopper 2002 and the sidewall 2003 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com