Automatic package clamping device for civil explosive automatic packaging assembly line

A technology for automatic packaging and civilian explosives, which is used in the storage of ammunition, ammunition, weapon accessories, etc. It can solve the problems of inability to meet the middle-package production line, backward automatic card loading devices, and many operation and maintenance personnel, and achieve effective automatic card loading operations. , Reasonable and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

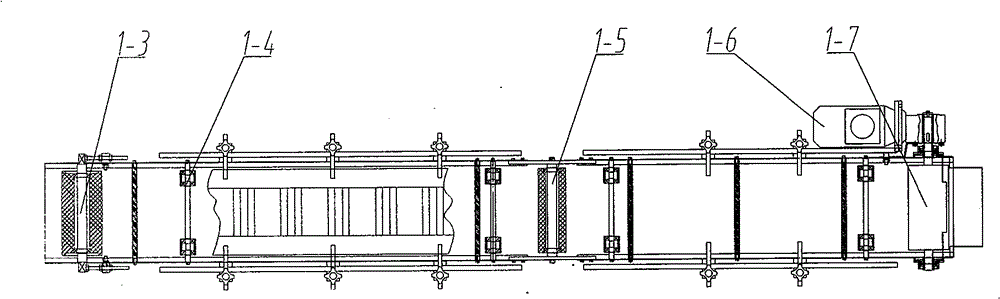

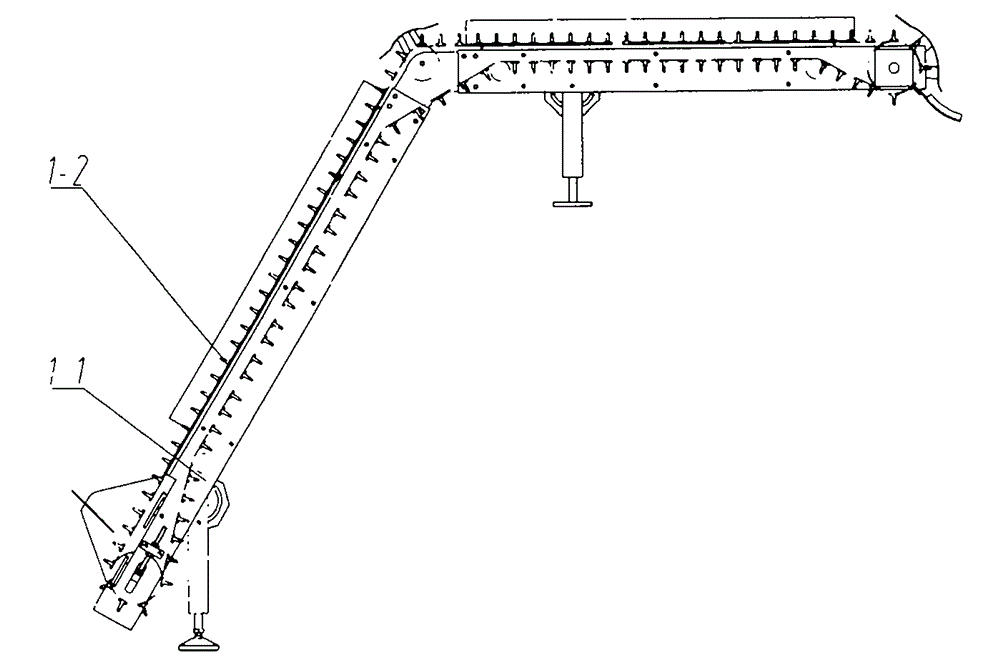

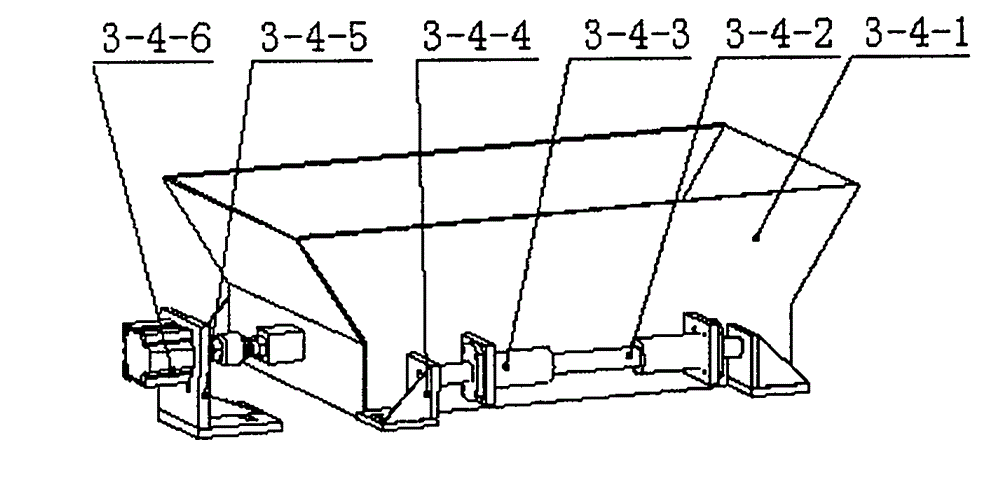

[0034] The present invention is mainly made up of four parts, as figure 1 As shown, that is: the oblique lifting belt conveyor 1 at the front end, the telescopic belt conveyor device 2 in the middle, and the vertical code card device 3. The inclined lifting belt conveyor 1 is composed of a horizontal part where the conveyor belt is arranged horizontally and an inclined part where the conveying belt is arranged obliquely. 2, the top of the conveying belt can transport the medicine roll to the conveying belt 2-2 in the middle telescopic belt conveying device 2. The inclined part of the inclined lifting belt conveyor 1 and the middle telescopic belt conveying device 2 are respectively fixed on the installation frame 2-5. The middle telescopic belt conveying device 2 is composed of a belt transmission mechanism and a telescopic cylinder 2-1. The belt transmission mechanism is composed of a conveyor belt 2-2 that is sleeved on the conveyor roller and a frame 2-3 that fixes the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com