Vertical code clamping machine

A code card machine and code card rack technology, applied in the field of packaging machinery, can solve the problems of low degree of automation, backward code card device, large floor space, etc., and achieve the effects of reliable performance, reasonable structure and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

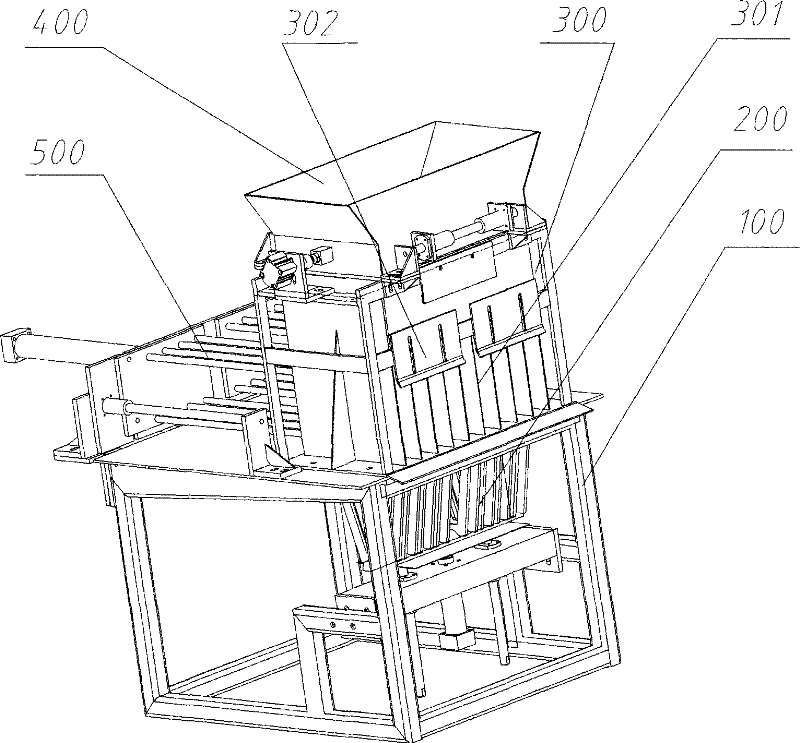

[0023] The present invention is mainly composed of a code card frame 100 , a drug ejecting rod assembly 200 , a vertical storage bin 300 , a vibrating hopper assembly 400 and a drug pushing rod assembly 500 . Such as figure 1 shown.

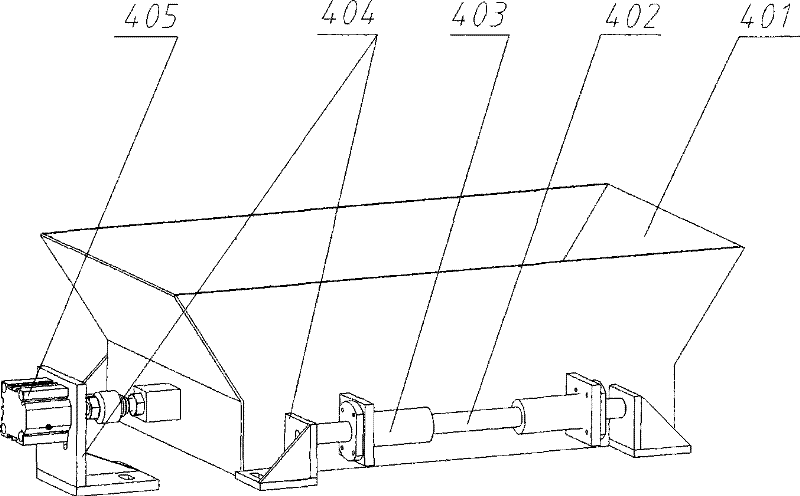

[0024] Wherein the vibration hopper assembly 400 is made up of a hopper 401 and a vibrator, the vibrator can be made up of a guide rod 402, a linear bearing 403, a mounting support 404 and an ultra-thin cylinder 405, the guide rod 402 is fixed on the mounting support 404, and the linear bearing 403 It is connected with the hopper 401, the guide rod 402 cooperates with the linear bearing 403, the cylinder body of the ultra-thin cylinder 405 is fixed on the installation support 404, the piston rod of the ultra-thin cylinder 405 is connected with the hopper 401, and is parallel to the guide rod 402, and the installation support The seat 404 is fixed on the vertical storage bin 300 , and the lower end of the hopper 401 is connected to the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com