Civil explosive middle package and boxing production line

A civilian explosive, production line technology, applied in the direction of ammunition, ammunition storage, weapon accessories, etc., can solve the problems of unstable floor space, high price, low production capacity, etc., and achieve the effects of reliable performance, simple operation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

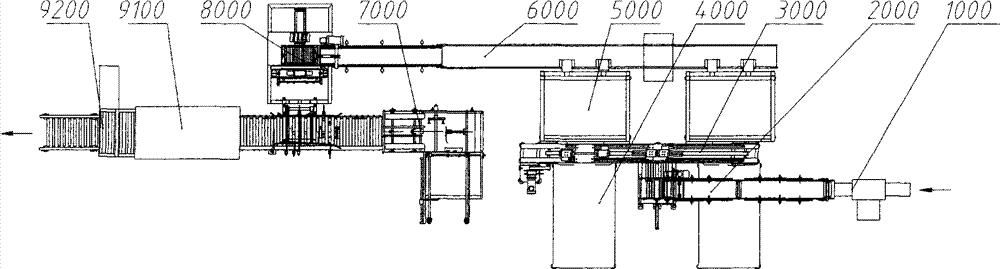

[0057] Such as figure 1 As shown, the present invention mainly consists of a single drug roll wax spraying device 1000, an automatic card code device 2000, a rail-type card seat conveyor 3000, a long push bag device 4000, a middle packaging bag sealing system 5000, an intermediate chain conveyor 6000, It is composed of 7000 unpacking and bottom sealing machines, 8000 side push box packing machines, 9100 folding cover sealing machines, and 9200 strapping machines.

[0058] General technological process of the present invention sees Figure 11 .

[0059] The layout of the production line of the present invention

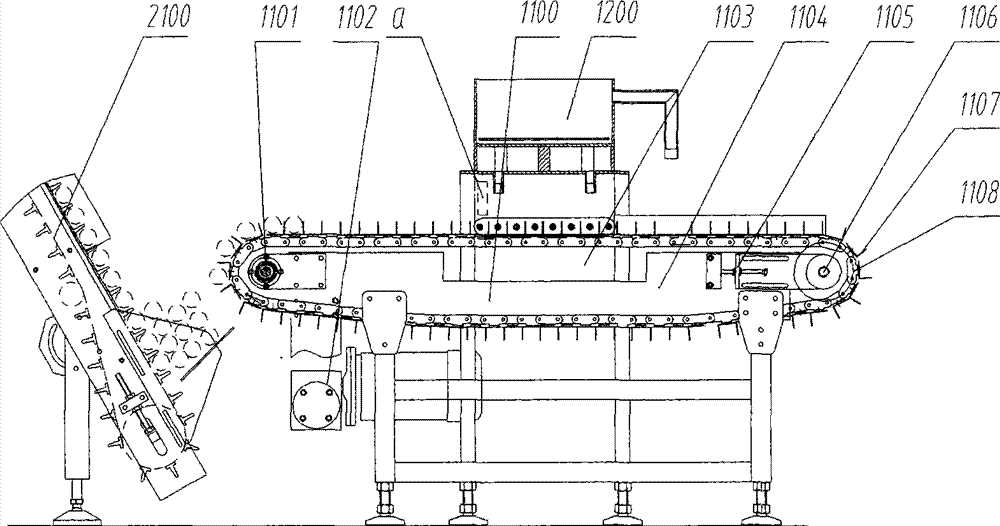

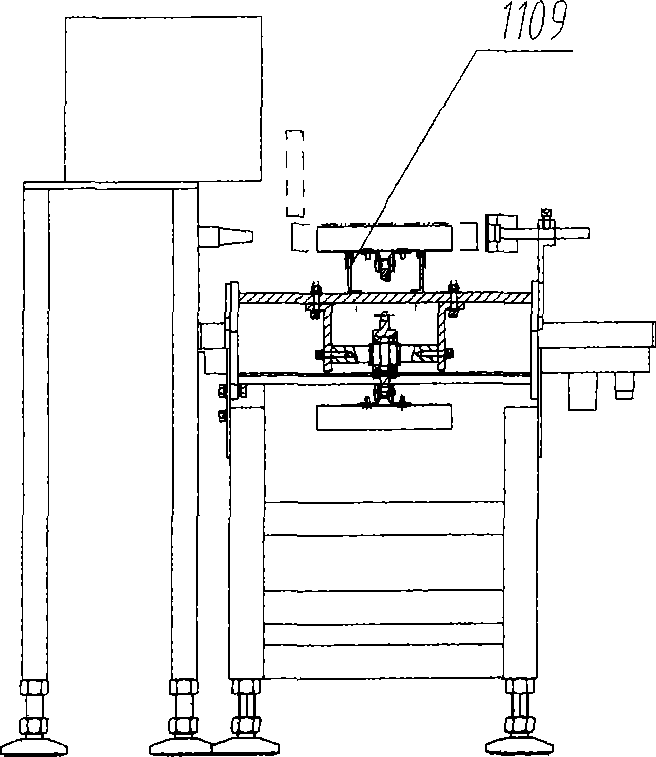

[0060] Such as figure 1 As shown, the front end of the chain conveyor 1100 in the single medicine coil wax spraying device 1000 is docked with the feeding port of the inclined lifting belt conveyor 2100 of the automatic code card device 2000, and the middle telescopic belt conveyor 2200 is installed on the fixed bracket. The drug outlet of the belt conveyor 2200 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com