Backlight module and lamp tube fixation assembly

A technology for a backlight module and a fixed component is applied in the field of backlight modules and lamp tube fixing structures, and can solve problems such as affecting the lamp tube fixing effect, difficult assembly of the lamp tube fixing structure, and dimension error of the lamp tube fixing structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

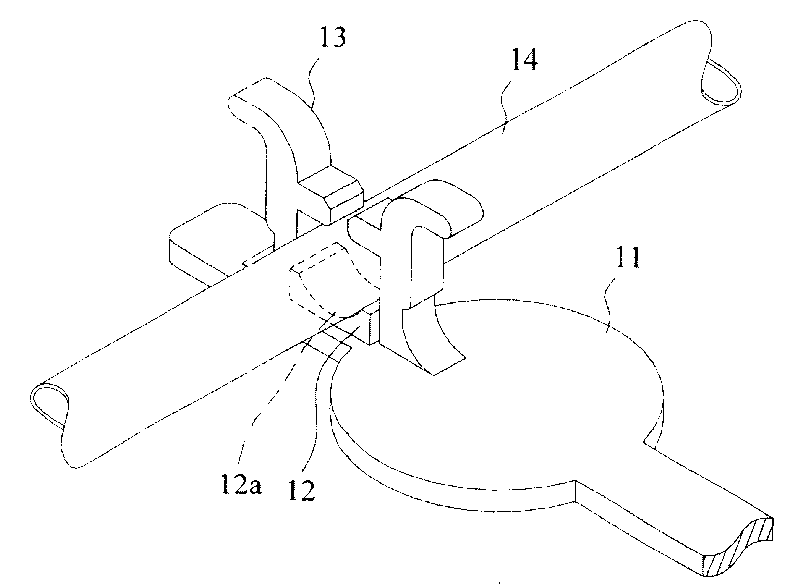

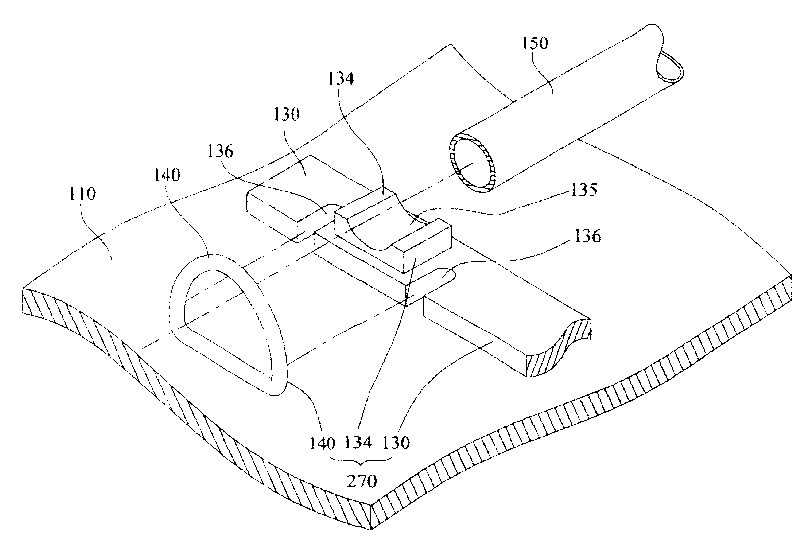

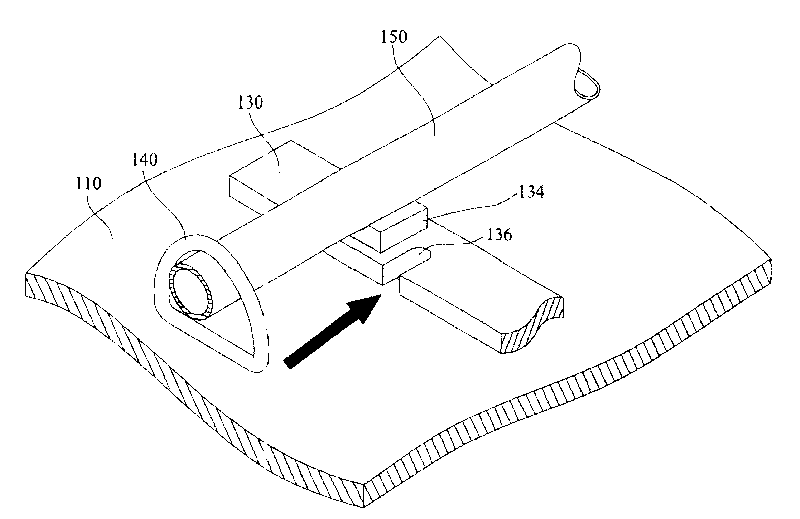

[0061] The invention provides a lamp tube fixing assembly for a backlight module, Figure 2A It is the first embodiment of the present invention. In this embodiment, the backlight module 100 includes a back plate 110 , a diffuser plate 120 , at least one lamp fixing component 270 and several lamps 150 . Wherein the diffuser plate 120 is arranged on the back plate 110 in parallel, and forms an accommodating space 100a with the back plate 110, for setting at least one lamp tube fixing component 270 and several lamp tubes 150, wherein the lamp tube fixing component 270 includes a The fixing seat 130 and several annular elastic members 140 . The backboard 110 has several embedding holes 114 , and the bottom surface of the fixing base 130 has several embedding columns 131 for inserting into each embedding hole 114 to fix the fixing base 130 on the backboard 120 . The bottom surface of the fixing base 130 also has a plurality of spacers 132 for making a gap between the fixing base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com