Pneumatic effect releasing facilities for underground bus stop of high-speed railway

A technology for underground stations and high-speed railways, applied in railway car body parts, stations, roads, etc., can solve problems such as the inability to meet the design requirements of the micro-pressure wave crest environment, achieve the effect of improving the waiting environment and comfort, meet the design requirements, alleviate the The effect of the aerodynamic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

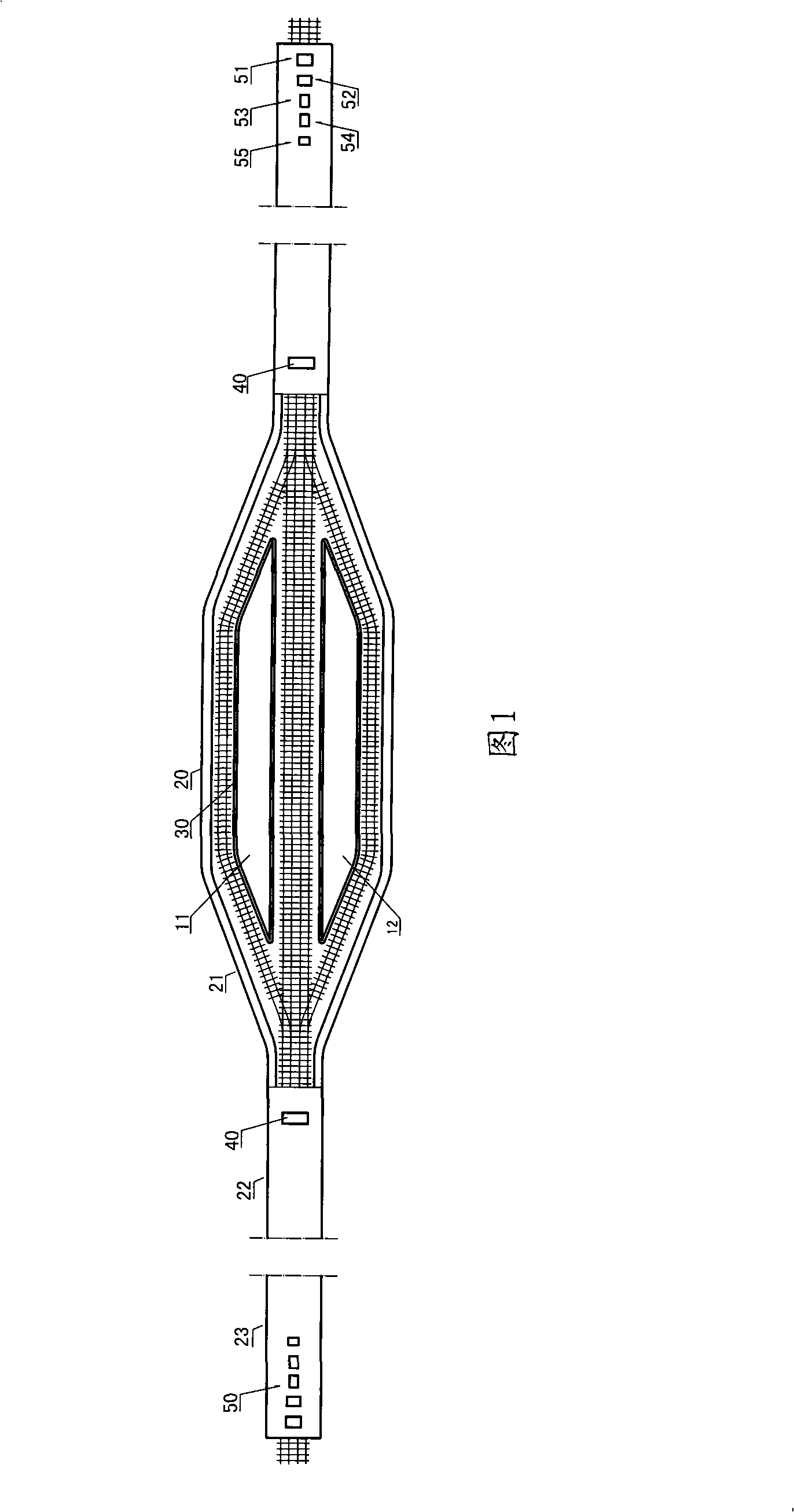

[0018] The aerodynamic effect mitigating facility of the high-speed railway underground station of the present invention comprises an underground space at both longitudinal ends communicating with the tunnel, and a platform arranged in the underground space. Referring to FIG. 1 , the transition section 21 forms a transition between the middle section 20 of the side wall of the underground space and the inner port of the tunnel. The trumpet-shaped transition section 21 can effectively reduce the peak value of the micro-pressure wave in the station, so that the micro-pressure wave generated in the station is less than 20Pa. Fig. 1 also shows a typical layout of the platform, that is, the platform is composed of two island platforms 11, 12 respectively located on both sides of the tunnel center line, between the main line and the arrival-departure line.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com