Cover cloth fixing structure

A technology for fixing structures and fixing components, applied in tents/canopies, building types, buildings, etc., can solve the problem of cumbersome fixing operation of cover cloth, and achieve the effect of easy cover cloth fixing operation and high operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

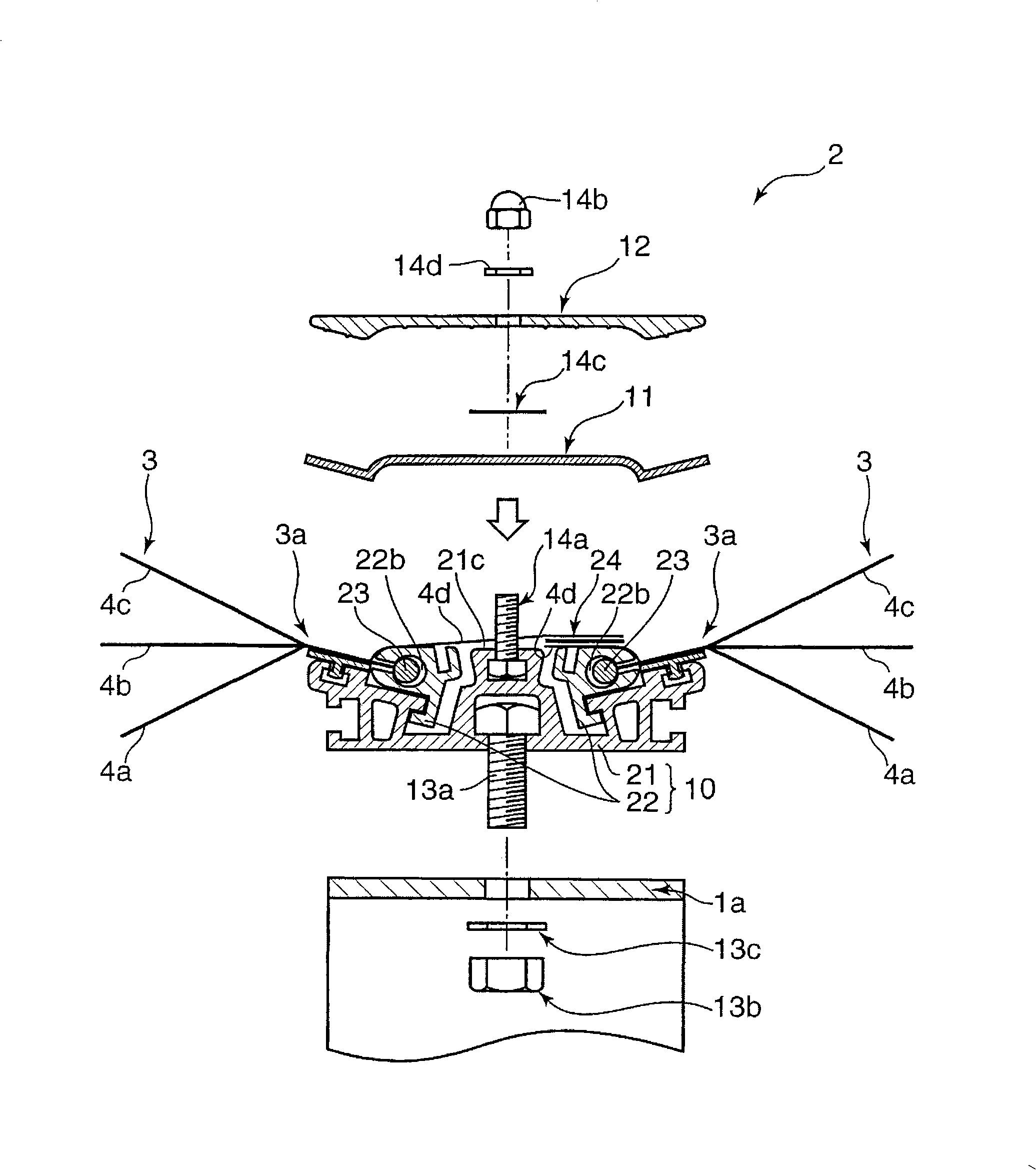

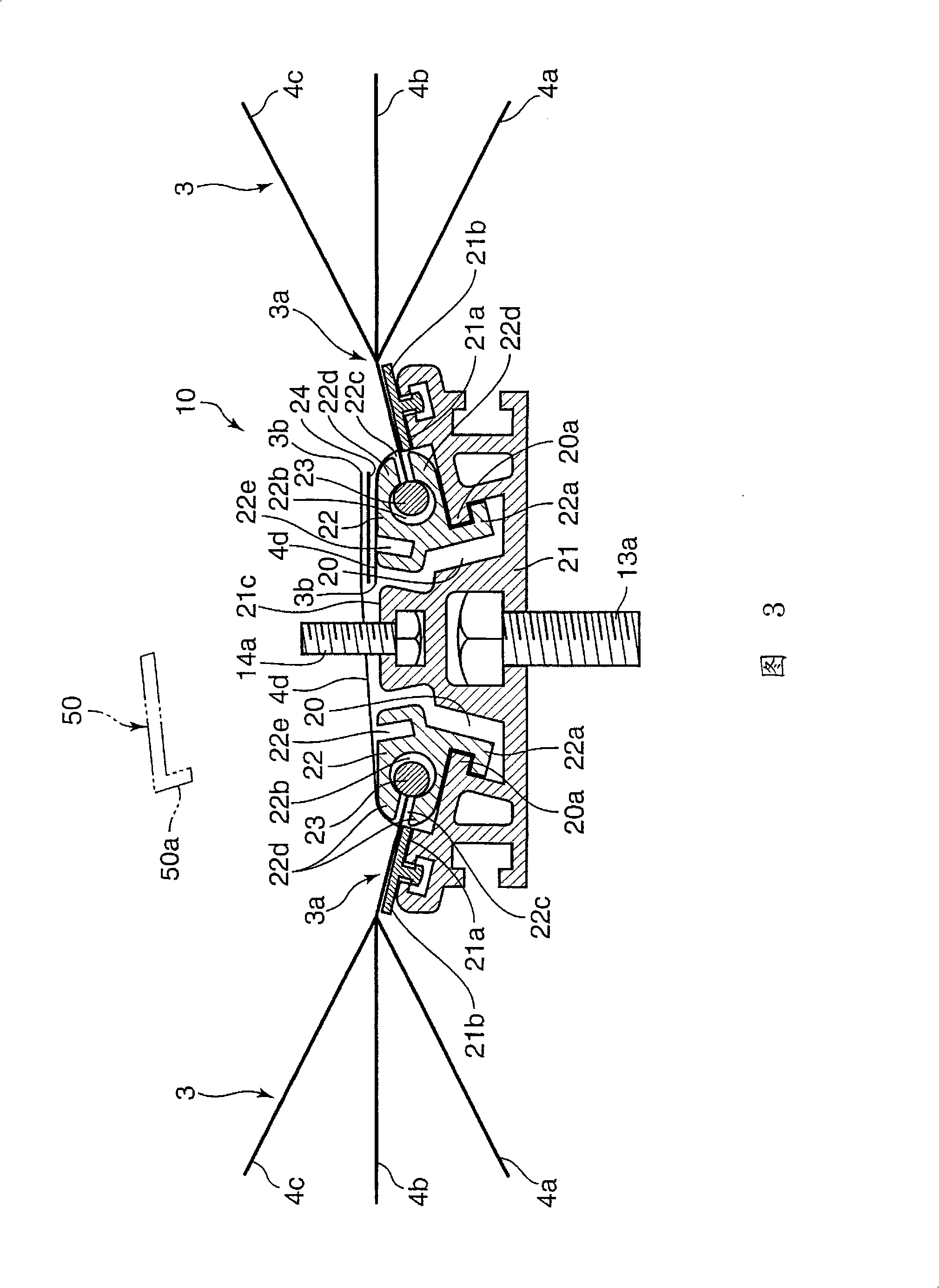

[0029] The embodiments of the present invention will be described in detail with reference to the drawings.

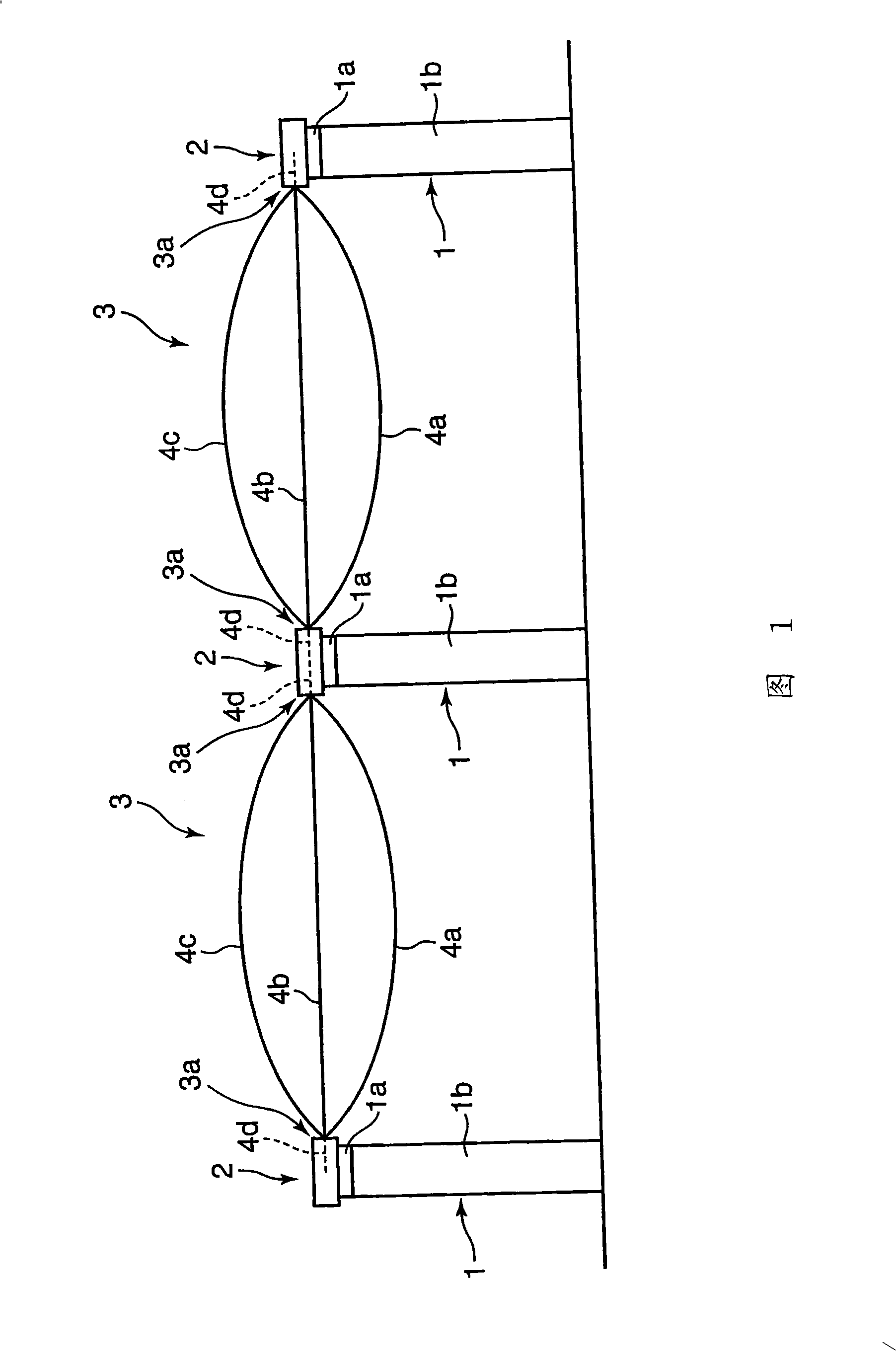

[0030] Fig. 1 is a front view schematically showing a structure to which a cover cloth fixing structure according to an embodiment of the present invention is applied.

[0031] The structure has: a plurality of rows of support frames 1 arranged in the left-right direction, in the example of the figure, there are 3 rows; a front support piece (not shown) connected to the front ends of the 3 rows of support frames 1; and the 3 rows of support frames 1 Rear side support piece (not shown) connected to the rear end. Each support frame 1 aligned in the left-right direction is composed of a horizontal plate 1a extending in the front-rear direction and pillars 1b provided at predetermined intervals on the lower side of the horizontal plate 1a. In addition, the cover cloth connection device 2 is provided on each horizontal plate 1a, and the cover cloth 3 is connected between the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com