Lens module, camera module and portable electronic products

A technology for lens modules and electronic products, applied in televisions, electrical components, color televisions, etc., can solve the problems of high cost, complicated lens manufacturing and installation, and large volume, and achieve easy installation, low cost, and simple drive structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

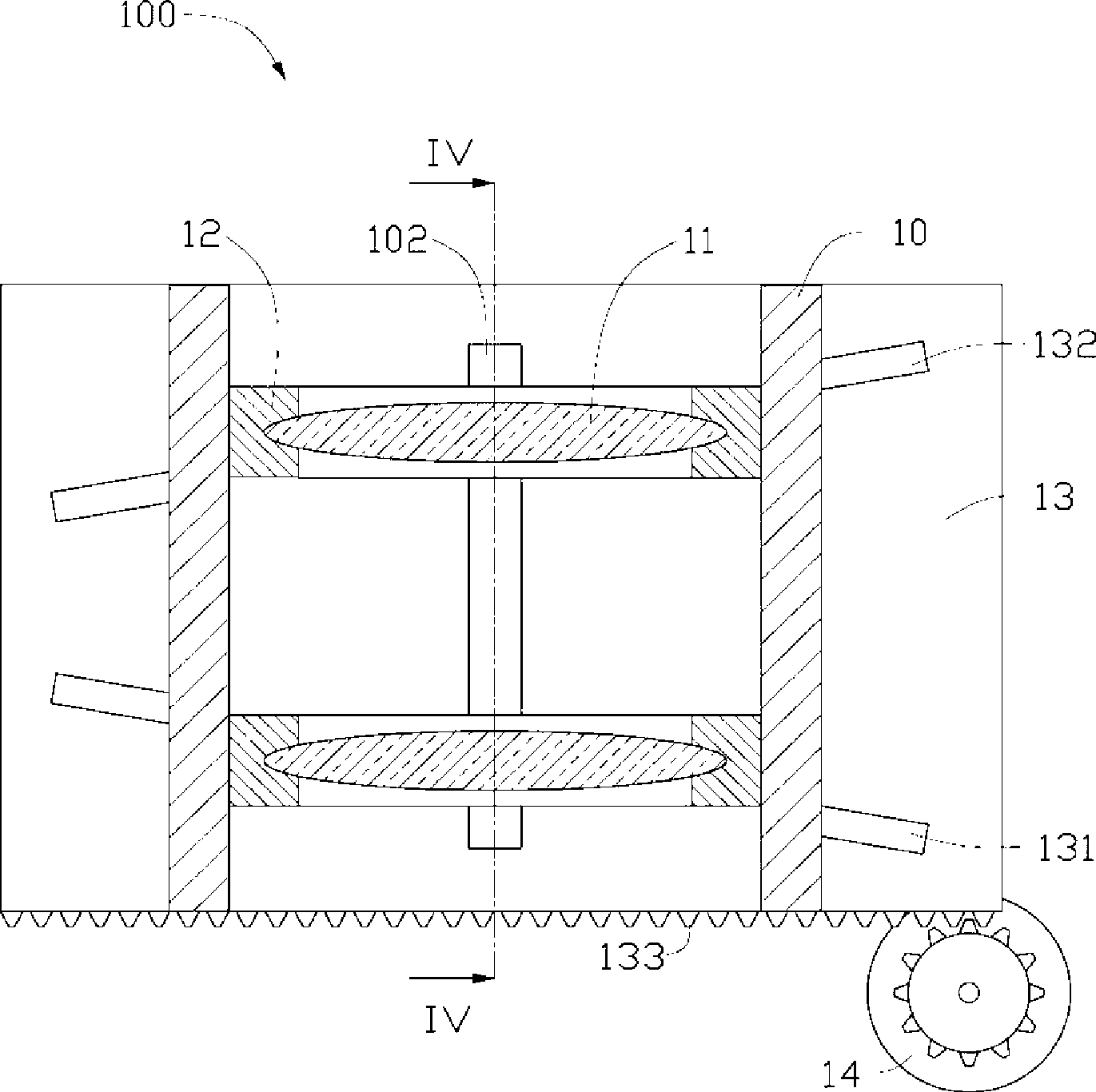

[0022] refer to figure 1 , the lens module 100 of the first embodiment includes a lens barrel 10 , two lens groups 11 , two brackets 12 , a focusing element 13 and a driving element 14 .

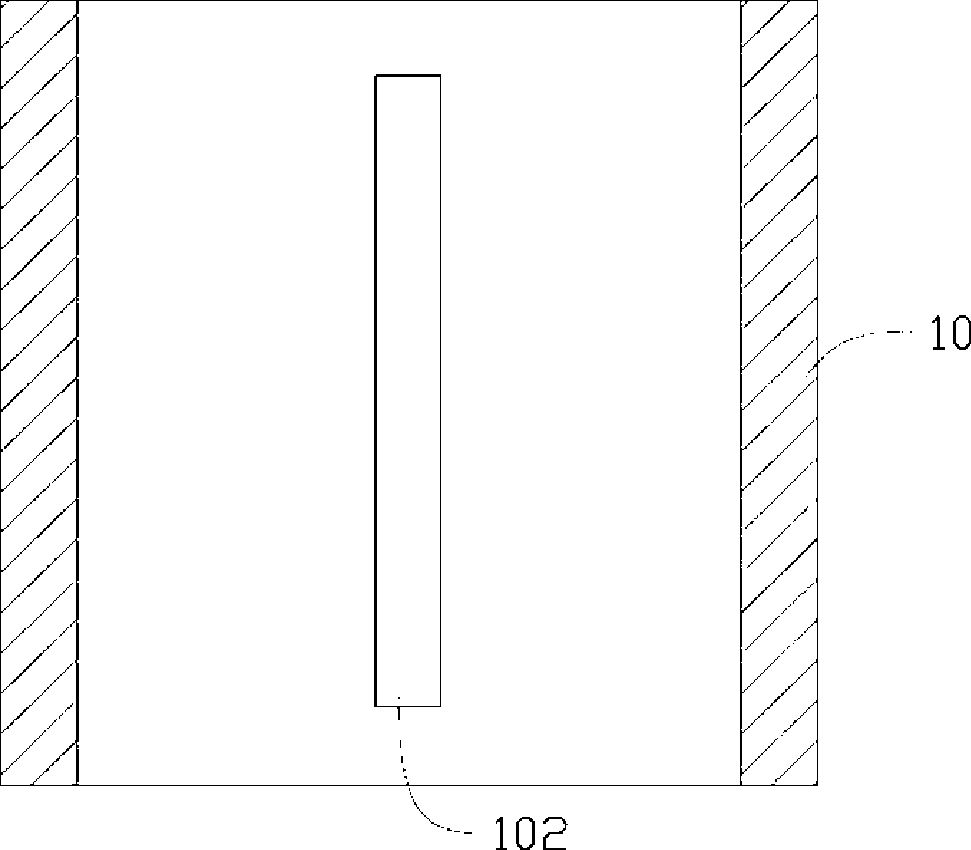

[0023] refer to figure 2 , an opening 102 extending axially along the lens barrel 10 is formed on the lens barrel 10 . The opening 102 is generally rectangular. Of course, the two ends of the opening 102 can also be processed into an arc shape.

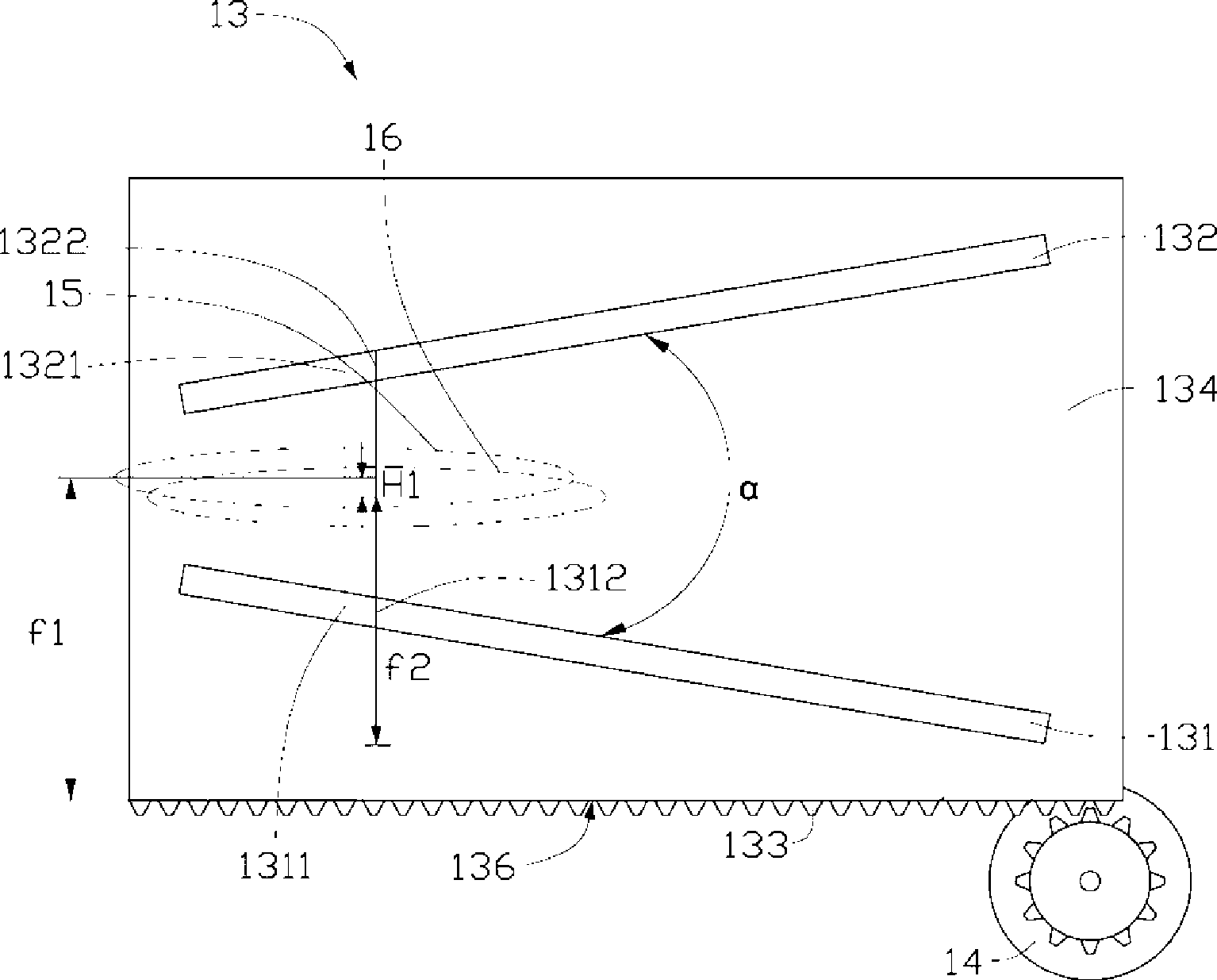

[0024] see also image 3 and Figure 4 , each bracket 12 includes a mounting portion 121 and a bar-shaped actuating portion 122 extending outward from the mounting portion 121 . The mounting portion 121 is cylindrical, and the lens group 11 is installed therein. The lens group 11 includes at least one lens. In this embodiment, one lens is taken as an example for illustration. The mounting portion 121 is integrally disposed on the inner surface of the side wall of the lens barrel 10 . The mounting portion 121 is slidably assembled with the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com