Air bag for vehicle tire sulfuration

A technology of automobile tires and airbags, applied in the field of airbags for vulcanization of automobile tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

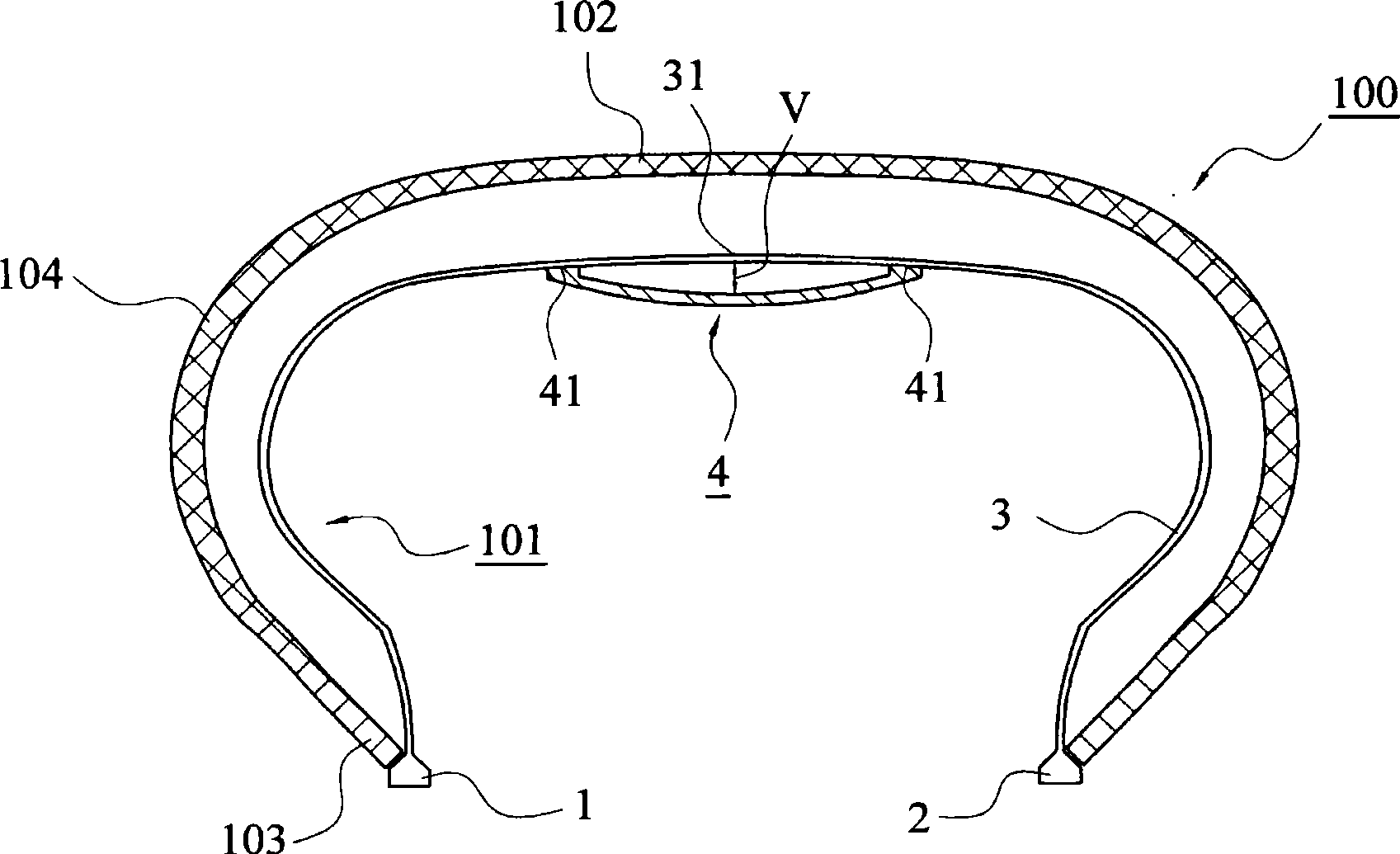

[0012] Hereinafter, the present invention will be described in more detail with reference to the drawings.

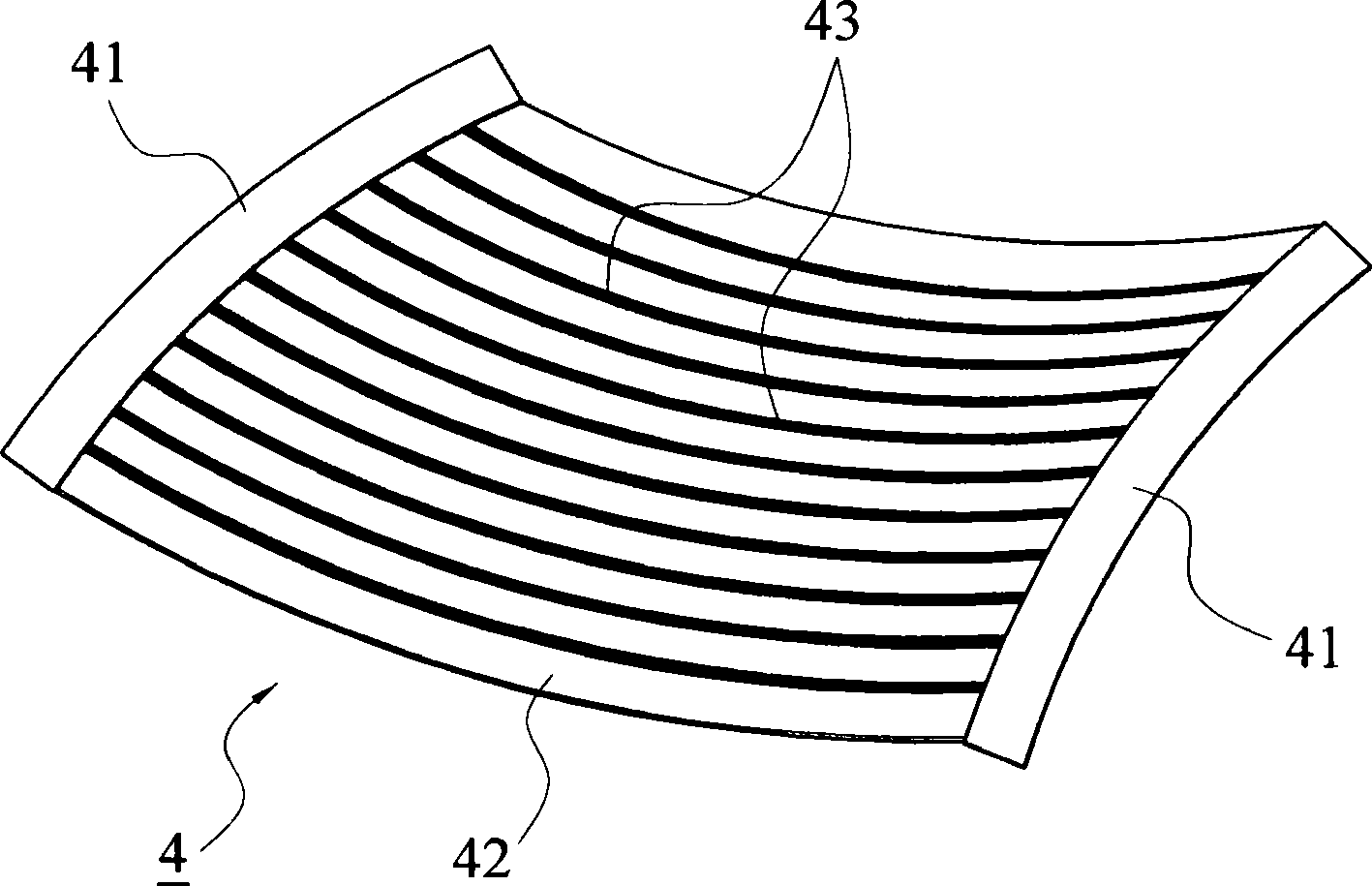

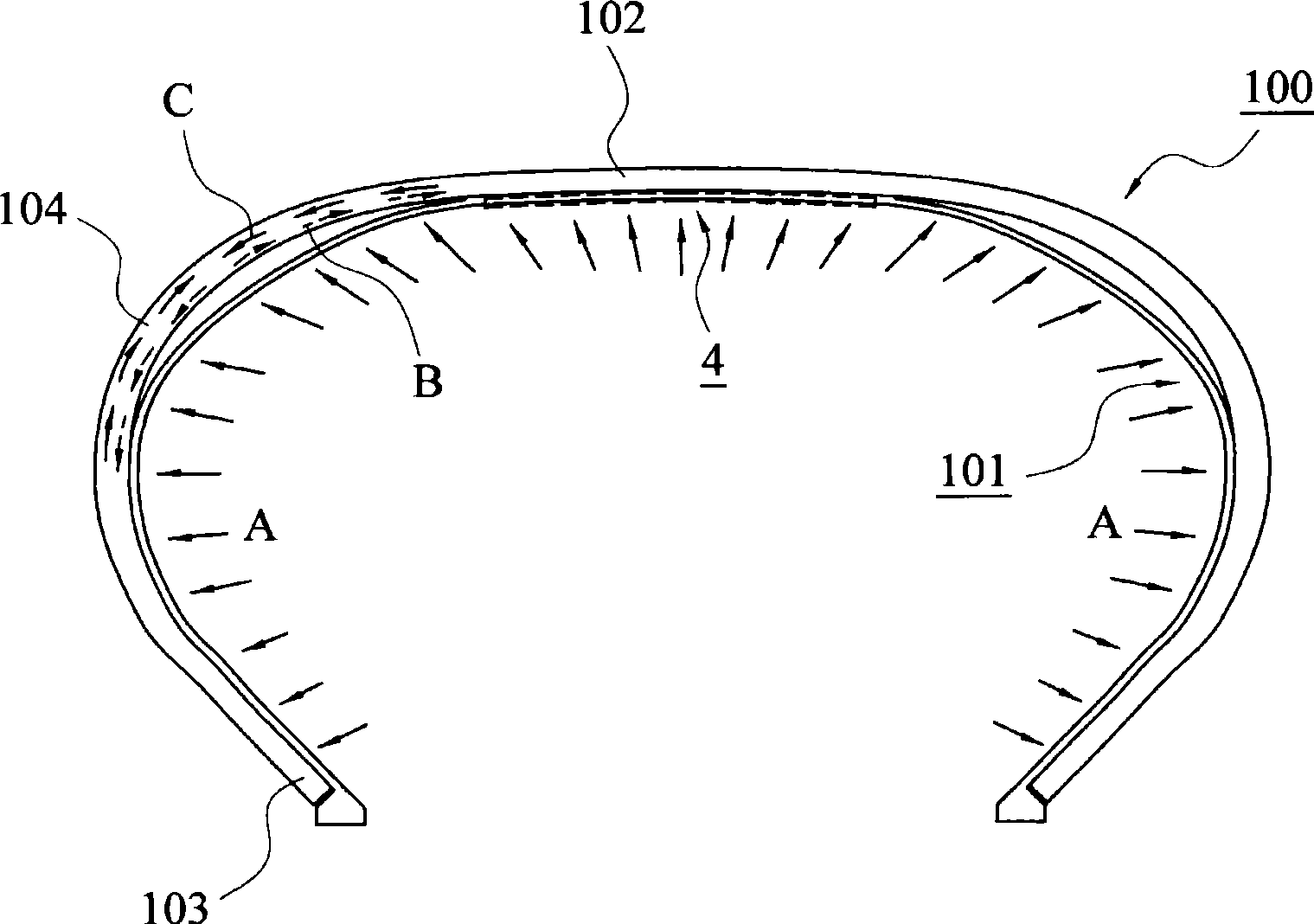

[0013] The present invention is an airbag for automobile tire vulcanization, which is located inside a raw tire 100 and integrates flanges 1, 2 and an inflatable part 3 on both sides that expand due to internal pressure during vulcanization. A reinforcing belt layer 4 is provided on the inner side of the center of the swelling part 3, and the above-mentioned reinforcing belt layer 4, such as figure 2 As shown, it is composed of the following composite materials, that is: the bonding part 41 on both sides, which is attached to the airbag 101 through an adhesive; Between: Nylon cords 43 are inserted and disposed inside the initial distillation rubber 42 at predetermined intervals.

[0014] When the above-mentioned reinforcing belt layer 4 is attached to the central portion of the airbag 101, the above-mentioned reinforcing belt layer 4 is provided so as to hang down fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com