Method for producing high-octane gasoline

A high-octane gasoline and catalyst technology, applied in the catalytic reforming of naphtha, etc., can solve the problems of high cost and high reaction temperature, and achieve the effects of increasing octane, reducing olefin content, and increasing aromatic content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The aromatization catalyst is ZSM-35 / MCM-22 eutectic molecular sieve, after being treated with water vapor at 550° C., the molecular sieve is impregnated with praseodymium nitrate solution so that the weight content of praseodymium is 1.5%. The aromatization reaction conditions are: reaction temperature 340°C, weight hourly space velocity 1.0h -1 , the reaction pressure is 1.5 MPa, and the ratio of C4 olefins to FCC gasoline is 16:84.

Embodiment 2

[0027] The aromatization catalyst is ZSM-5 / MCM-22 composite molecular sieve. After being treated with water vapor at 500°C, the molecular sieve is dipped in tungstic acid solution so that the weight content of tungsten is 2%. The aromatization reaction conditions are: reaction temperature 360°C, weight hourly space velocity 2.0h -1 , the reaction pressure is 1.5MPa, and the ratio of C4 olefins to FCC gasoline is 10:90.

Embodiment 3

[0029] The aromatization catalyst is Y molecular sieve. After being treated with water vapor at 550° C., cerium nitrate solution is impregnated on the molecular sieve to introduce 4% cerium. The aromatization reaction conditions are: reaction temperature 350°C, weight hourly space velocity 4.5h -1 , the reaction pressure is 2.0MPa, and the ratio of C4 olefins to FCC gasoline is 80:20.

[0030] The aromatization reactor that embodiment 4-6 adopts and mode of operation are as follows:

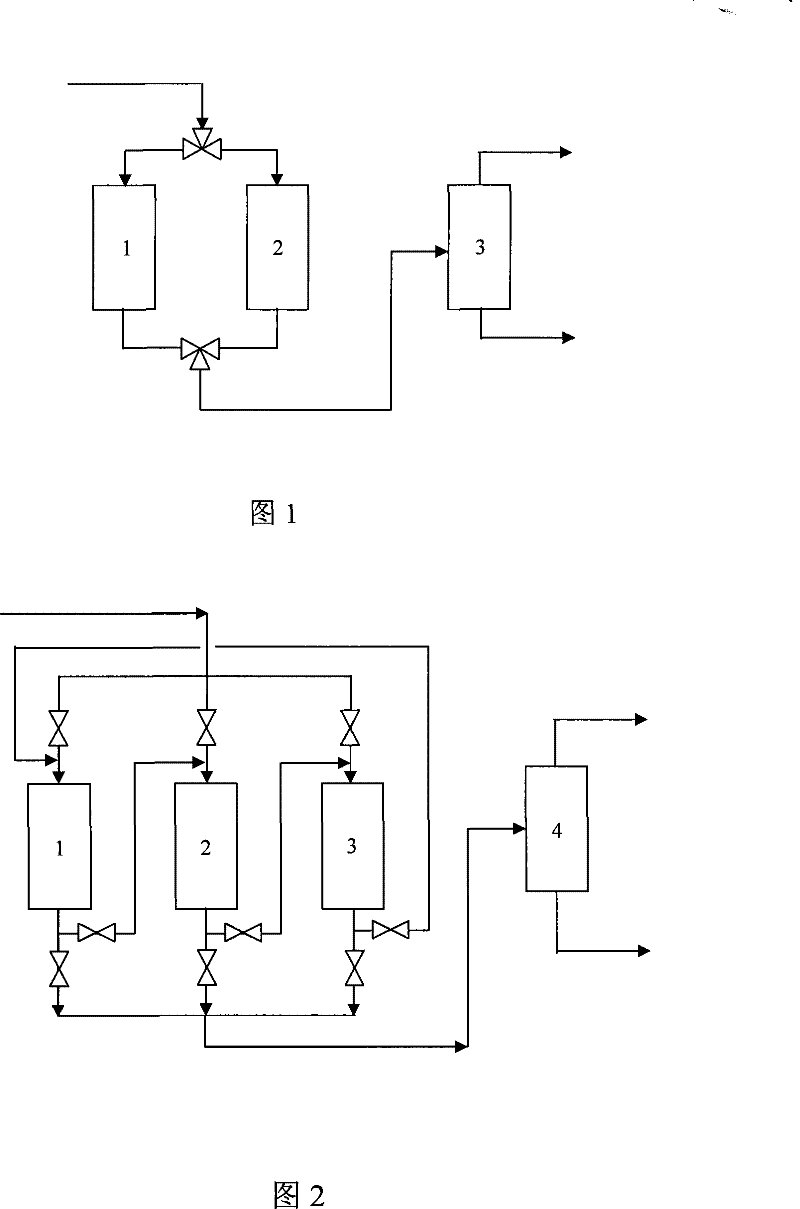

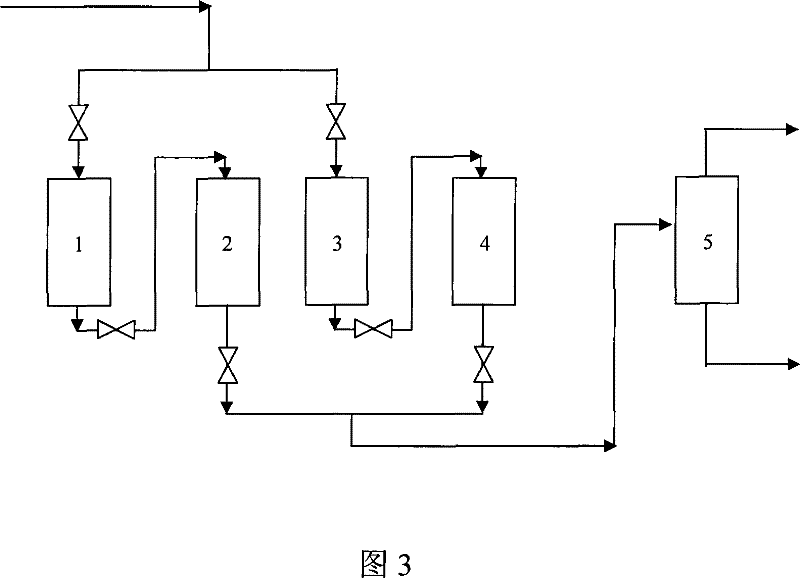

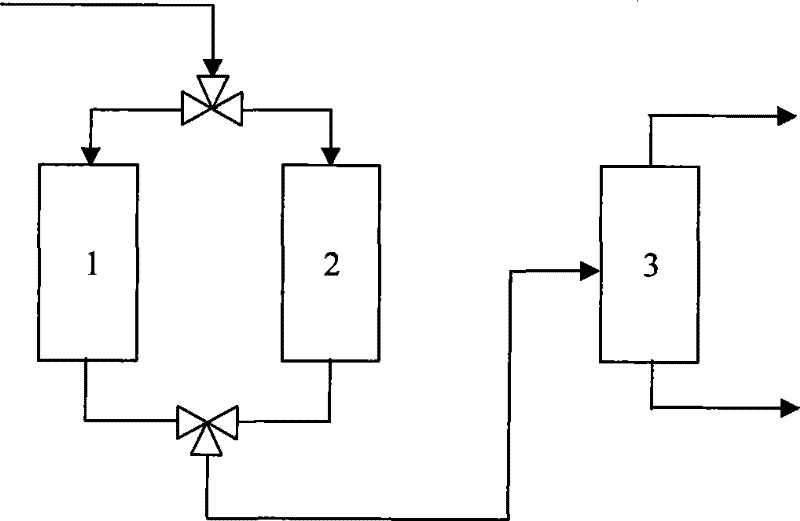

[0031] A simulated moving bed with three fixed bed reactors connected in series is used as the aromatization reactor. figure 2 A schematic diagram of the reaction. Three fixed-bed reactors 1, 2, 3, and 4 are used as product separation equipment. Each reactor is equipped with raw material inlet valve and inlet pipeline, product outlet valve and outlet pipeline, and a communication valve and communication pipeline are provided between each reactor and the next reactor, that is, the material can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com