Temperature-controlled consolidation pressure chamber system

A pressure chamber and surrounding pressure technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problem that the triaxial consolidation pressure chamber cannot carry out high temperature and variable temperature load tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

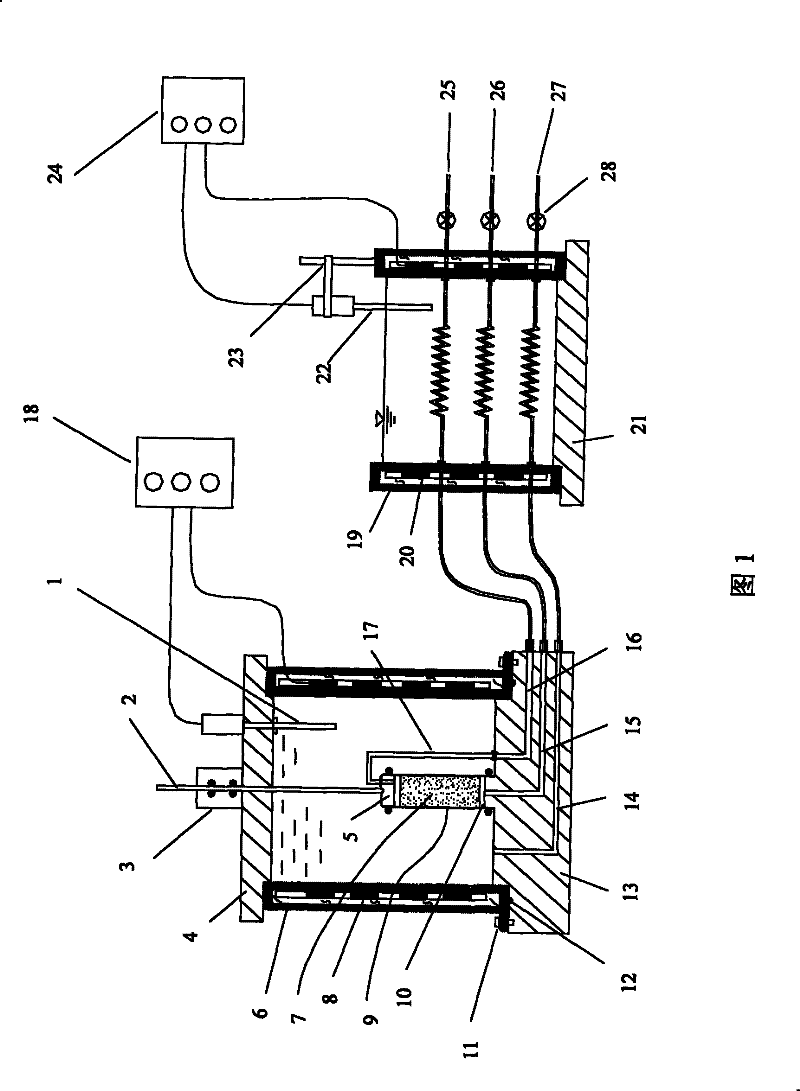

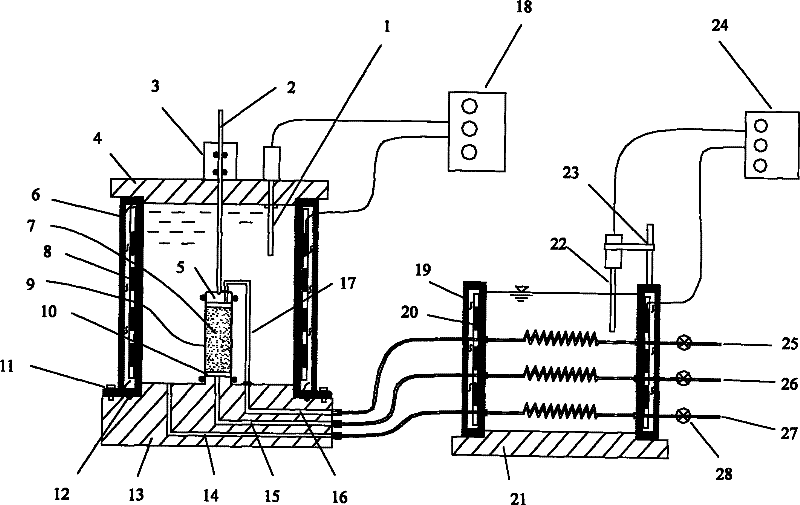

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

[0014] The temperature-controlled consolidation pressure chamber ( figure 1 )’s top cover (4) is welded to the pressure chamber side wall (6); the pressure chamber side wall (6) is connected to the pressure chamber base (13) through fixing bolts (11), and is sealed by an O-shaped rubber ring (12); The axial pressure rod (2) is in contact with the sample cap through the water-stopping shaft sleeve (3) through the center of the top cover (4); the sample (7) is placed in the pressure chamber base (13) of the pressure chamber The permeable stone (10) at the center is connected to the permeable stone on the top of the sample (7) and the sample cap (5); the sample (7) is surrounded by an impermeable cylindrical rubber film (9); Both ends of the drain pipe (17) are respectively connected with the top of the sample cap (5) and the inlet of the sample drain hole (16) on the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com