Apparatus for controlling die cushion of press machine

A buffer mechanism and mold technology, applied in digital control, program control, electrical program control, etc., can solve problems such as inability to accurately implement bottom dead center locking, bottom dead center position deviation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

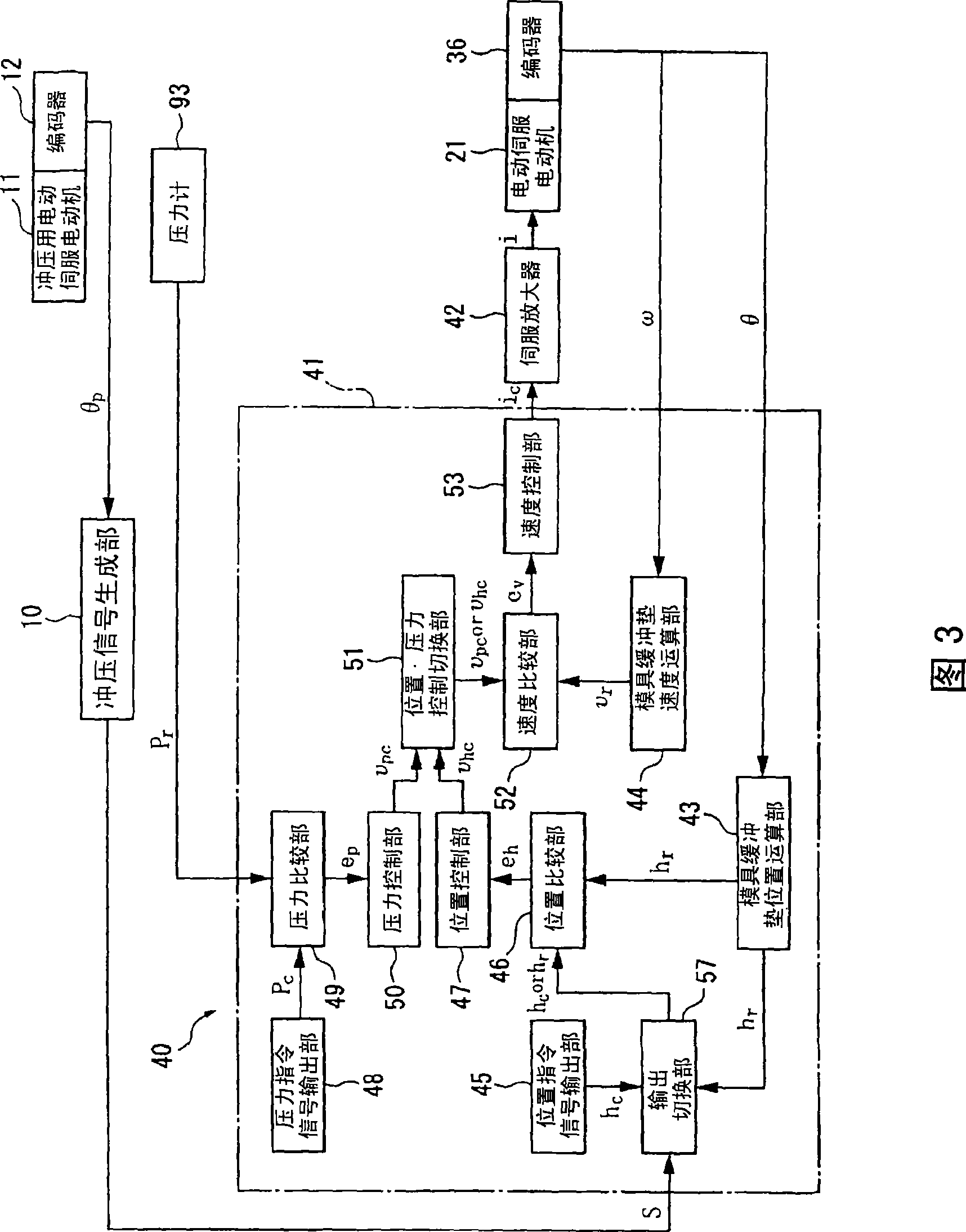

[0052] Next, specific embodiments of the mold cushioning mechanism control device of the present invention will be described with reference to the drawings.

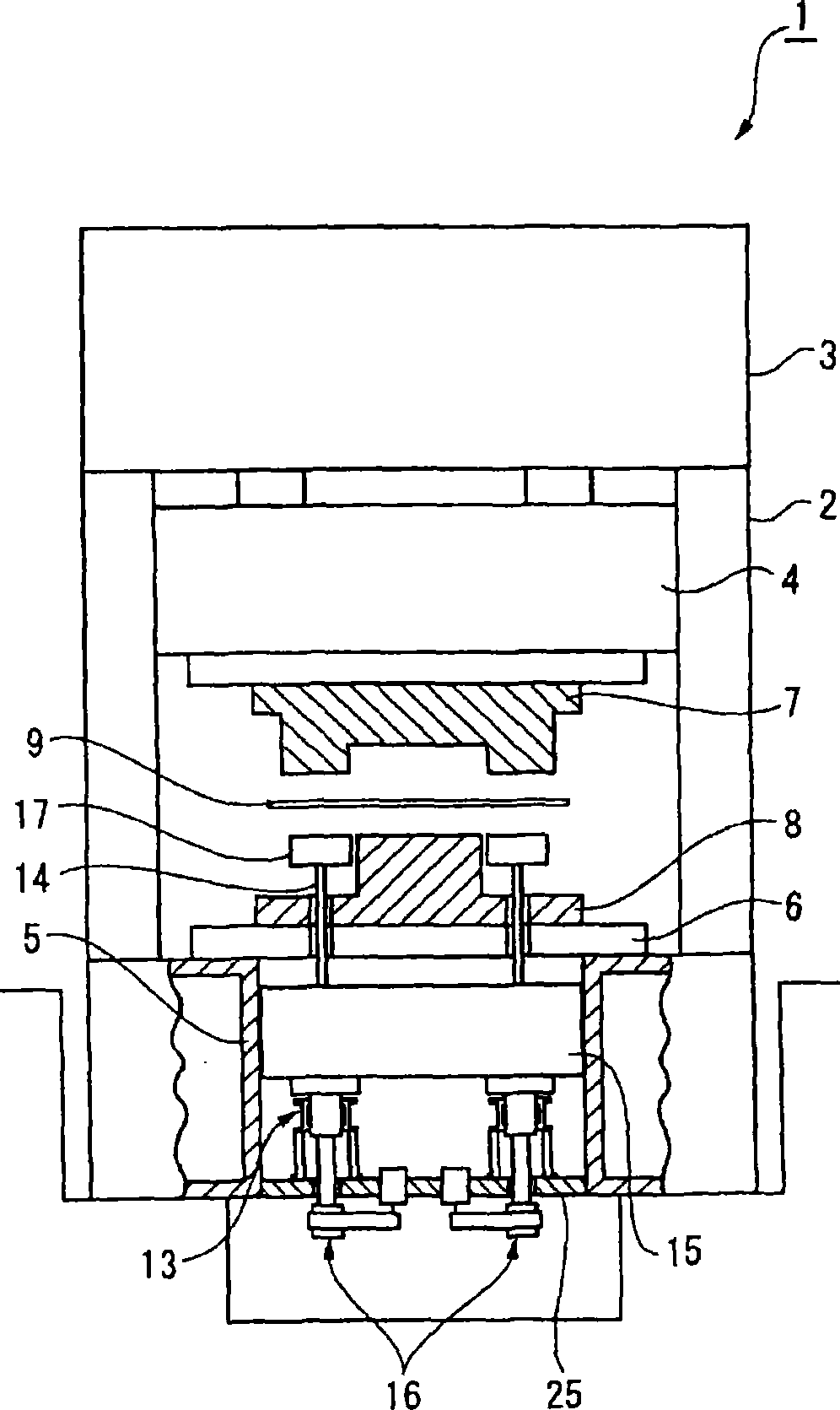

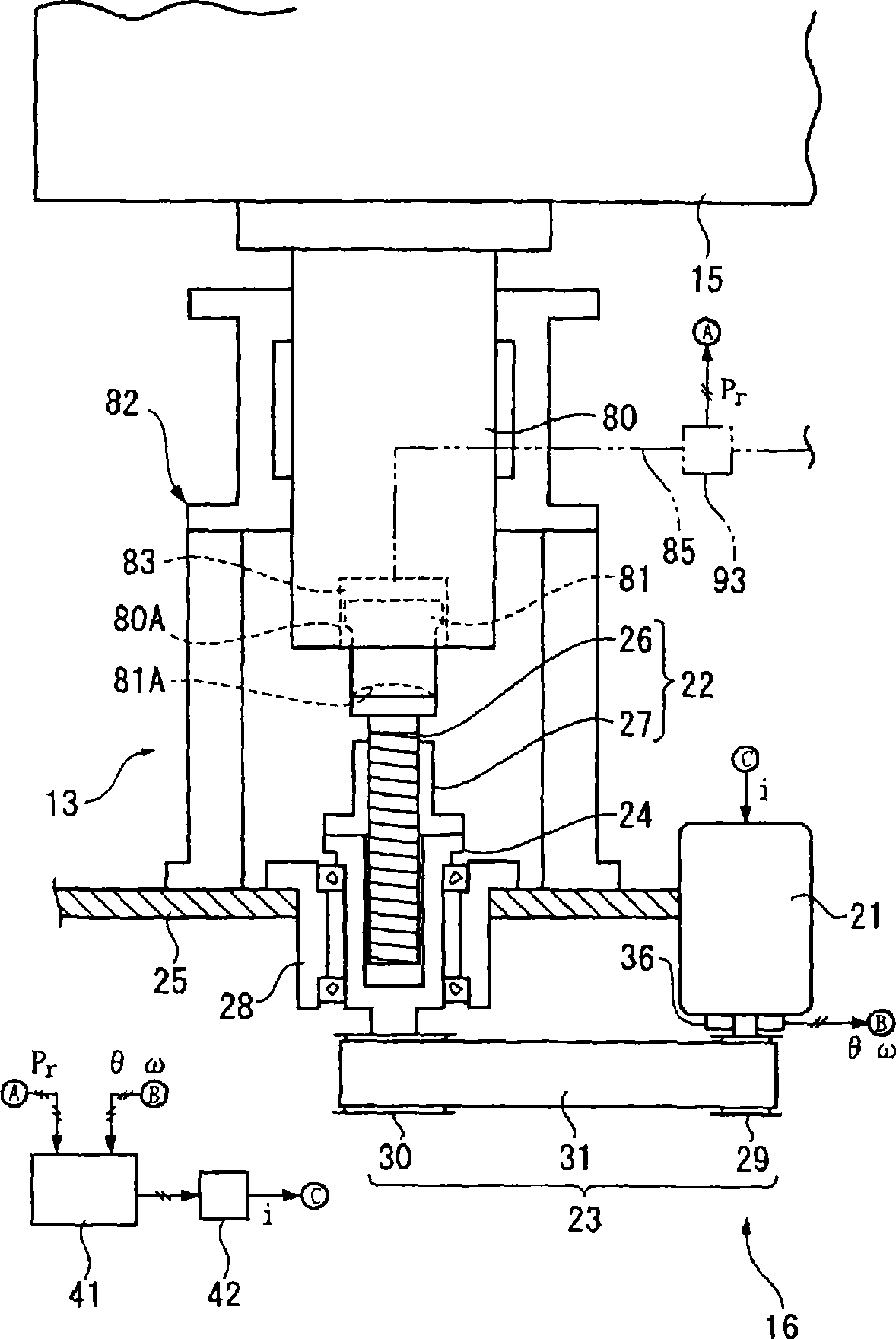

[0053] figure 1 A schematic configuration diagram showing a press machine according to an embodiment of the present invention. figure 2 A schematic configuration diagram showing the die cushion mechanism 13 of the first embodiment.

[0054] figure 1 The stamping machine 1 shown has: a slider 4, which is freely supported on the main body frame 2, and driven up and down by the slider driving mechanism 3; a backing plate 6, which is arranged opposite to the slider 4 and installed on the bed 5 superior. An upper mold 7 is installed on the lower surface of the slider 4 , and a lower mold 8 is installed on the upper surface of the backing plate 6 . In this manner, press working (drawing) is performed on the workpiece 9 arranged between the upper die 7 and the lower die 8 by the lifting operation of the slider 4 .

[0055...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com