Brake caliper

A brake caliper and disc brake technology, applied in the field of brake calipers, can solve the problems of increasing fuel consumption, small return movement, and noise generation, and achieve the effects of optimizing air gap performance, optimizing motion performance and deformation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

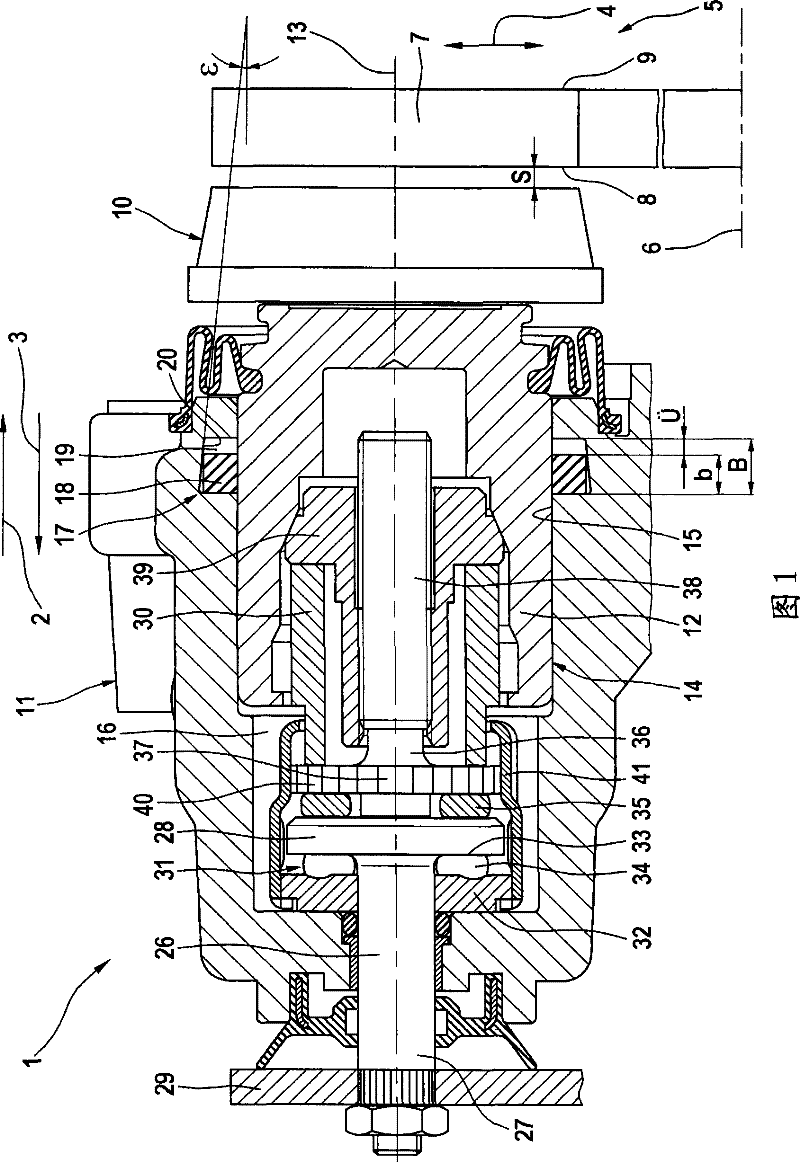

[0018] figure 1 A disc brake is shown with a brake caliper 1 , a brake lining 10 and a brake disc 5 , only the parts of these components that are relevant for the invention being shown. The brake caliper 1 itself comprises a caliper housing 11 and a piston 12 arranged to be movable in a bore 14 along the bore axis for braking operation. By displacing the piston 12 in the direction of application of pressure, the piston 12 pushes the brake lining 10 against the axial friction surface 8 of the friction ring 7 of the brake disk 5 . The brake disk 5 is mounted pivotably about a pivot axis 6 . Shelled bridge not shown ( ), the housing bridge extends beyond the brake disc 5 so that the other axial friction surface 9 of the friction ring 7 can be loaded by means of another brake lining.

[0019] In the case of service braking, the displacement piston 12 is acted upon by means of hydraulic pressure. For this purpose, the piston 12 and the caliper housing 11 form a pressure chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com