Rubber pressure atomizer

A sprayer and pressure technology, which is applied in the device, application, animal husbandry and other directions of catching or killing insects, can solve the problems of explosion, high power and high air pressure, and achieve the effect of convenient use, comfortable use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

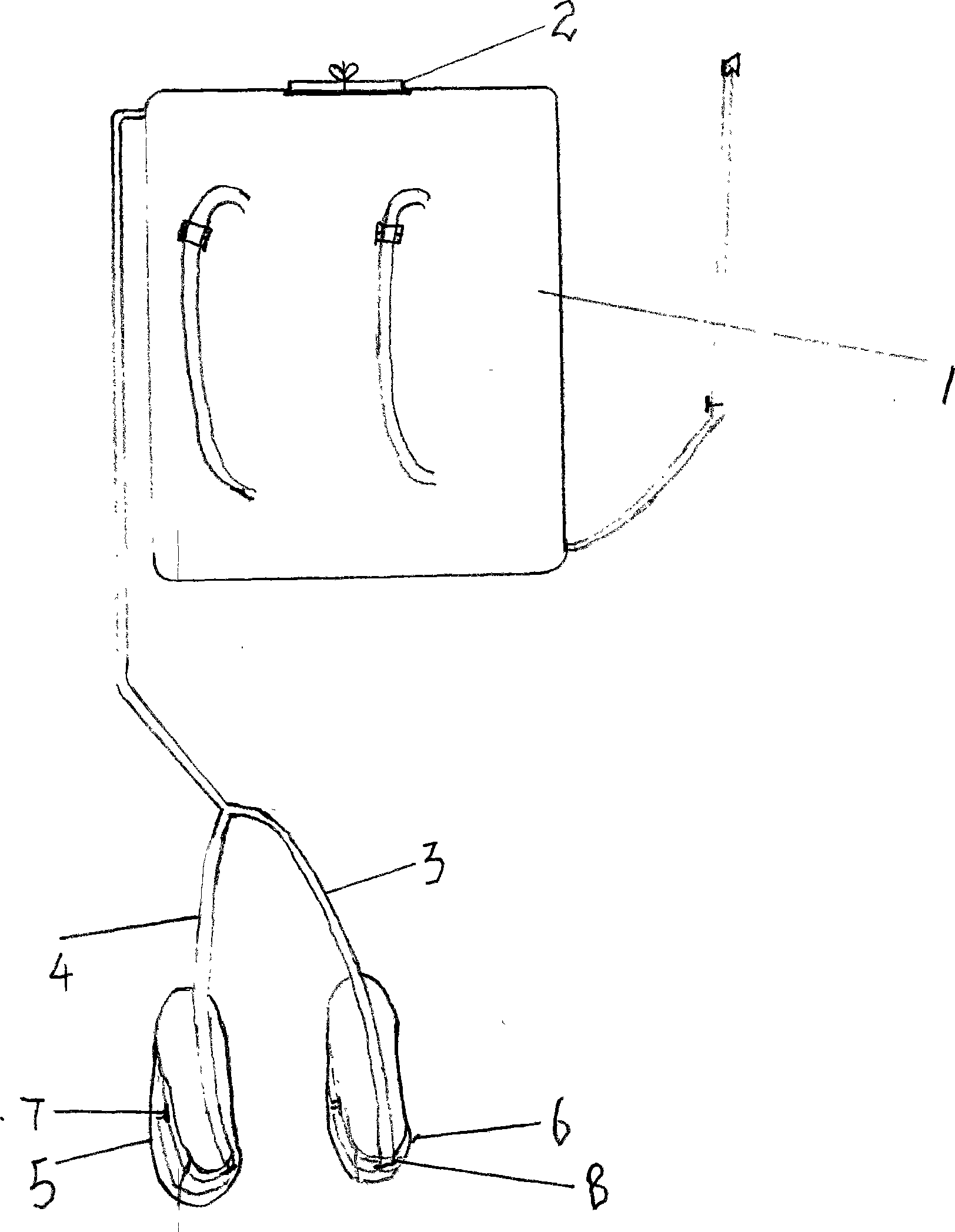

[0009] In the figure, the elliptical iron ring is the sealing port 2 on the upper part of the rubber bag 1, the iron cover with the elliptical rubber edge is the sealing cover 3, which can be placed in the sealing port 2 with the elliptical iron ring, and the built-in pump 4 is on the upper side of the rubber bag 1 , the air pressure gauge 5 is on the other side of the top of the rubber bag 1, the liquid medicine opening screw 6 is on the bottom side of the rubber bag 1, and the outlet pipeline 7 is connected with the medicine liquid opening screw 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com