Hydraulic wiper blade

A wiper blade and hydraulic technology, applied in the field of hydraulic wiper blades, can solve the problems of uneven force on each point of the rubber strip, affecting the wiping cleanliness, high cost, etc., so as to improve the wiping cleanliness and service life, reduce the The effect of water ripples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

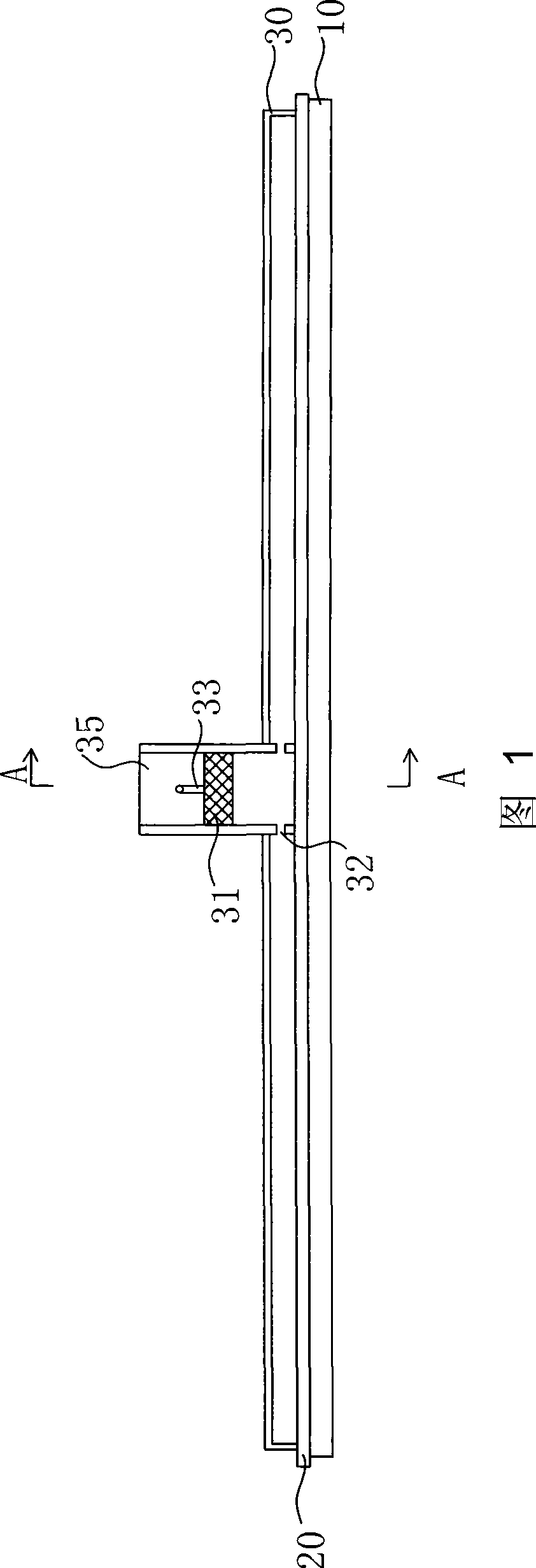

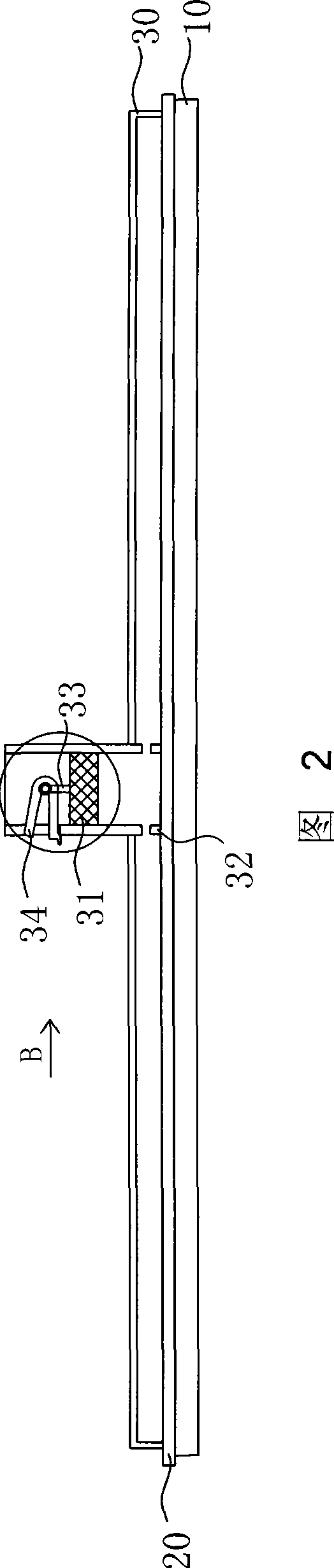

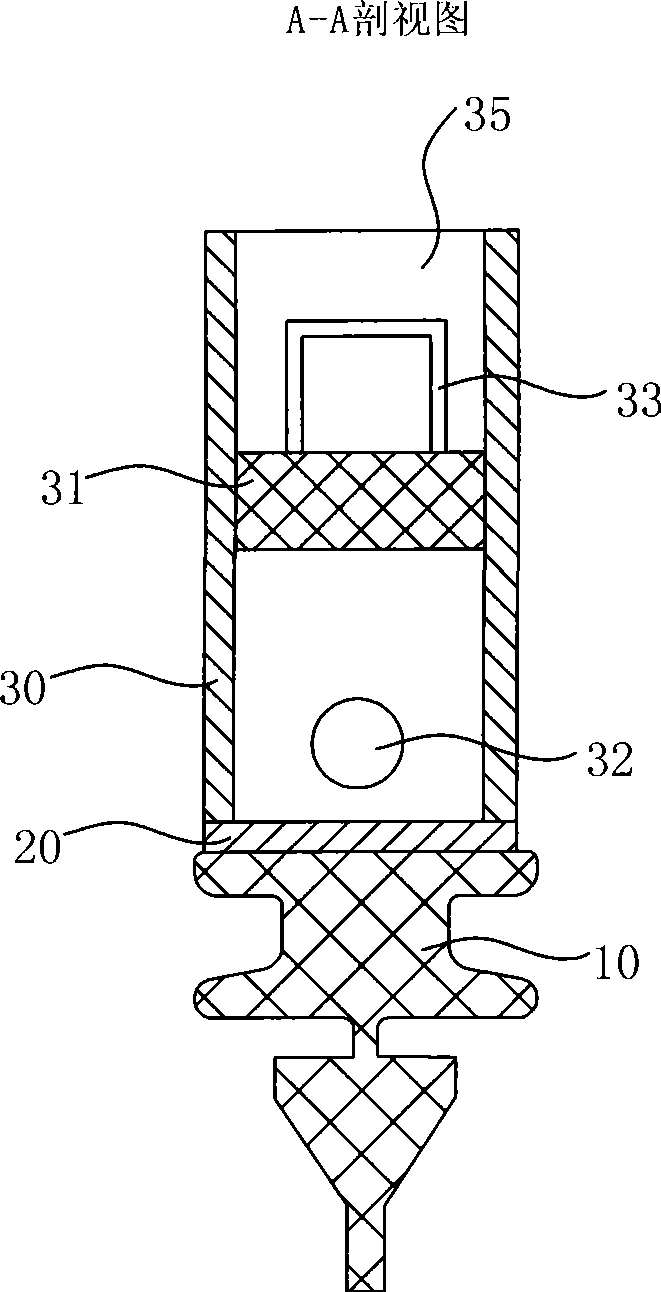

[0013] A hydraulic type wiper blade, including a rubber strip 10, the back of the rubber strip 10 is fixedly connected to a compression spring 20, the front of the rubber strip 10 is closely attached to the windshield on the outside of the car, the rubber strip 10 and the compression spring 20 are both The elongated chamber housing 30 with a rod-shaped groove section that matches the curved surface of the windshield and the pressure spring 20 enclose a hydraulic chamber, and the chamber is filled with a liquid 40, which is a liquid with a low viscosity. , such as engine oil, etc., the chamber housing 30 is provided with a cylinder portion 35 for accommodating the piston 31, and a seal is provided between the piston 31 and the chamber housing 30 to prevent the liquid 40 from flowing out of the chamber housing 30, and the piston 31 is in the exposed exterior and The scraping rod 50 is clamped and fitted, as shown in FIGS. 1 , 2 and 5 .

[0014] 2, 3, 5, the profile of the cavity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com