Single-windmill, single-motor, vertical-wheel and multi-stage wind power tower

A single-motor, windmill technology, applied to wind power generator components, wind power generation, wind power generators at right angles to the wind direction, etc., can solve the problem that the vertical axis power generation mode cannot become the main force of wind power generation equipment, the vertical axis of power is weakened, and the vertical axis Self-heavy and other problems, to achieve the effect of avoiding the reduction of power generation, saving equipment investment, and improving the utilization rate of wind energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention can be explained in more detail with reference to the following examples; however, the present invention is not limited to the combination of these examples.

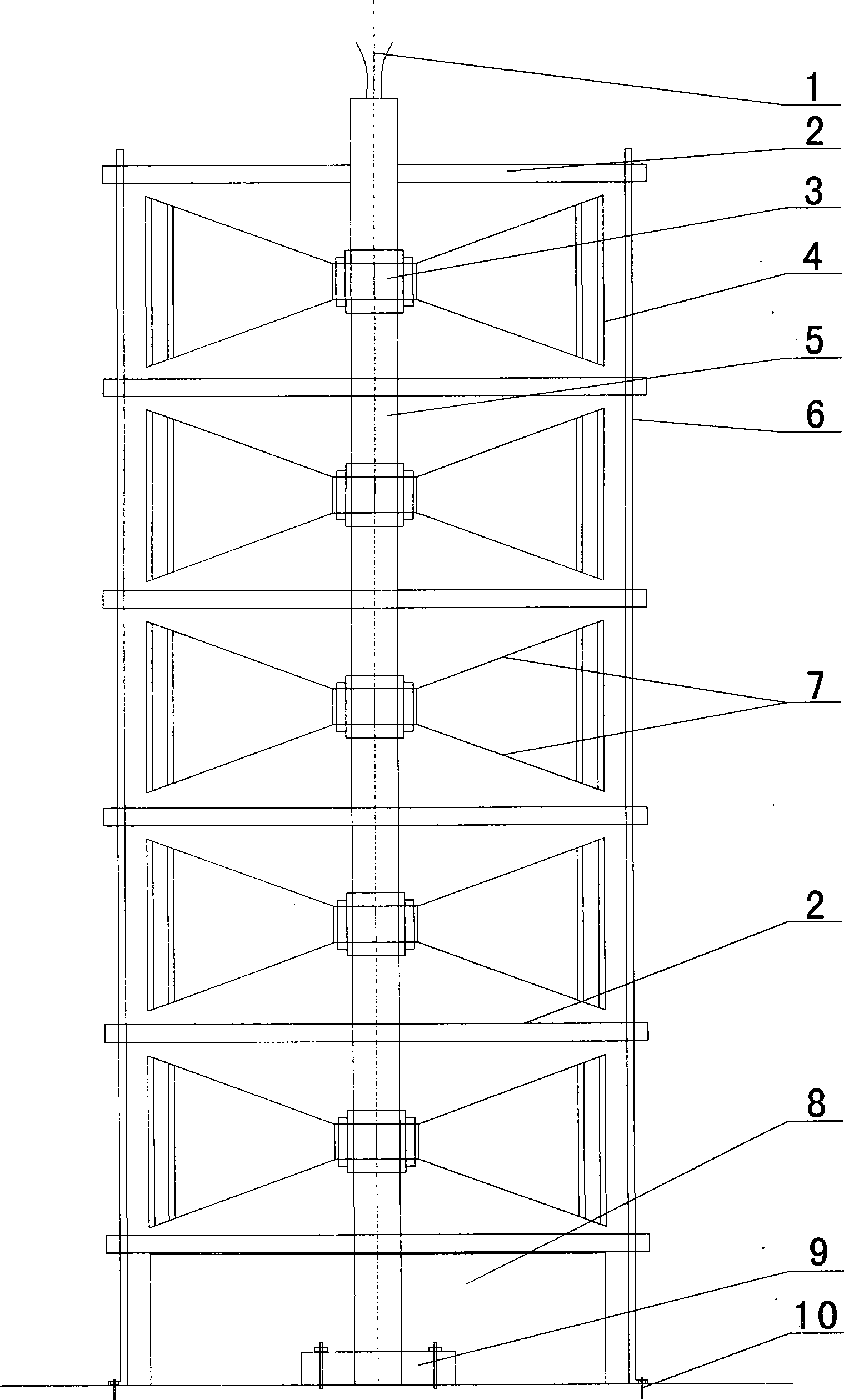

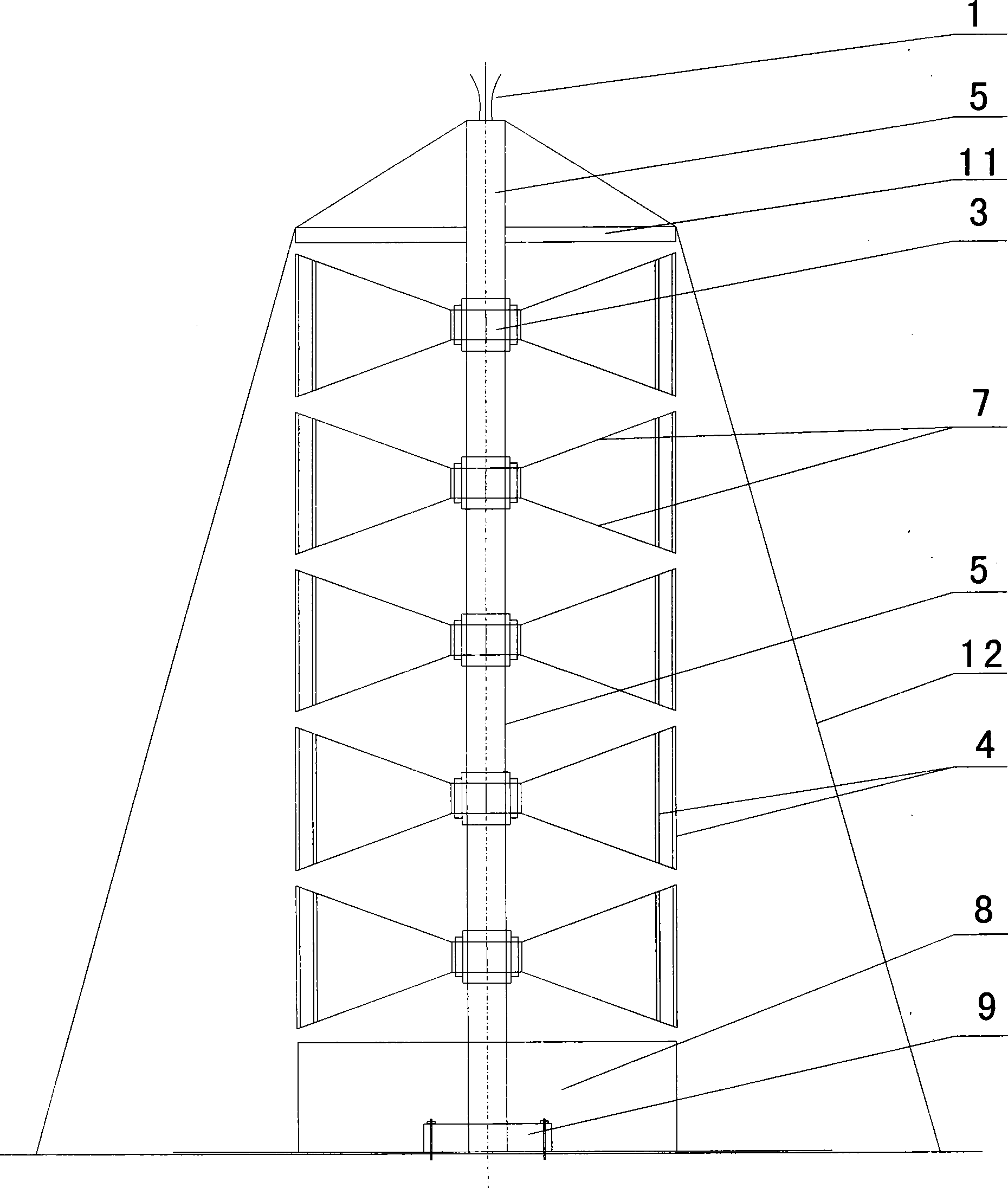

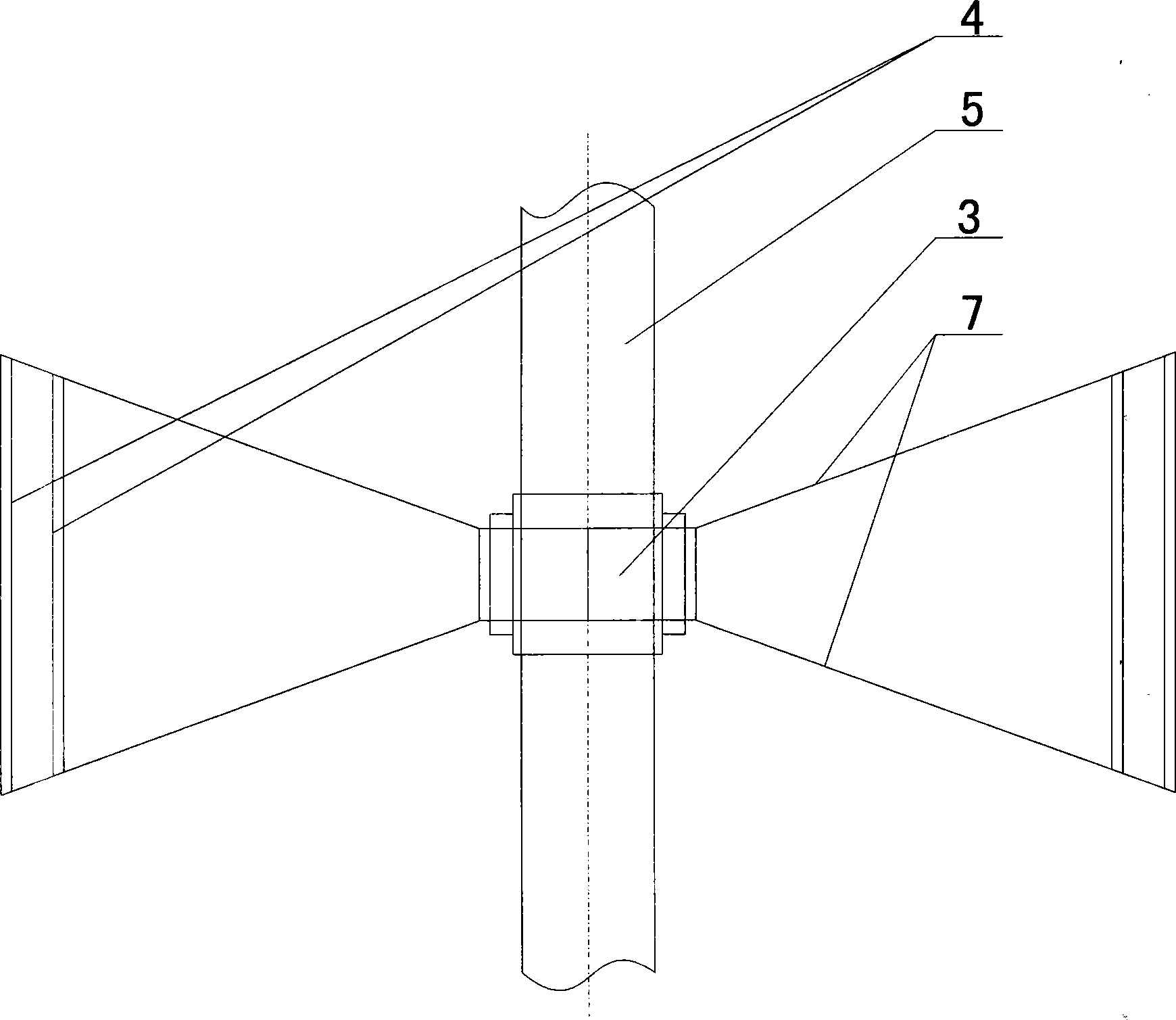

[0020] exist figure 1 , 2 , 3, 4, 5 or one of a single windmill single motor vertical wheel multi-stage wind power tower, including the wind blade 4 structure for absorbing wind energy, the generator 3 structure for power generation, and the multi-layer power generation structure for series connection Central cylinder 5; the structure of the blade 4 for absorbing wind energy includes the blade 4 and the connecting rod 7 of the blade, and the upper and lower ends of the blade 4 are respectively connected to the outer ends of the connecting rod 7 of the blade. The outer rotor sleeve of the machine 3 is provided with a link structure connecting the inner end of the fan blade connecting rod 7, and the central column 5 runs through the center of the stator of the generator 3 to form a set of win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com