Shield mounting structure of helmet

A technology for installing structures and shields, which is applied to helmets, helmet covers, clothing, etc., can solve the problems of high production cost, troublesome installation, and unnaturalness, and achieve the effect of easy cost reduction, low cost, and simple assembly and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, embodiments of the present invention will be described based on the drawings.

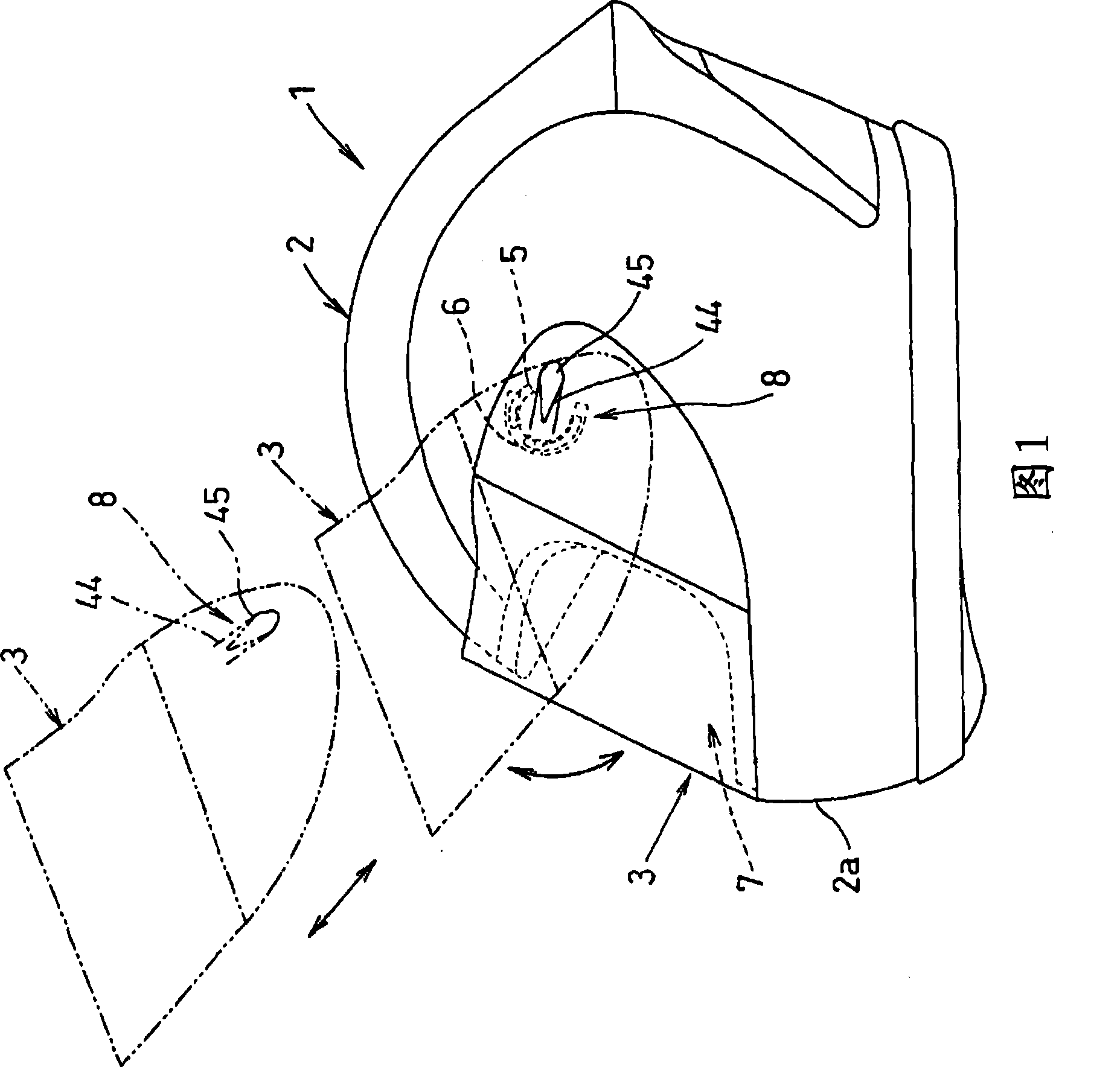

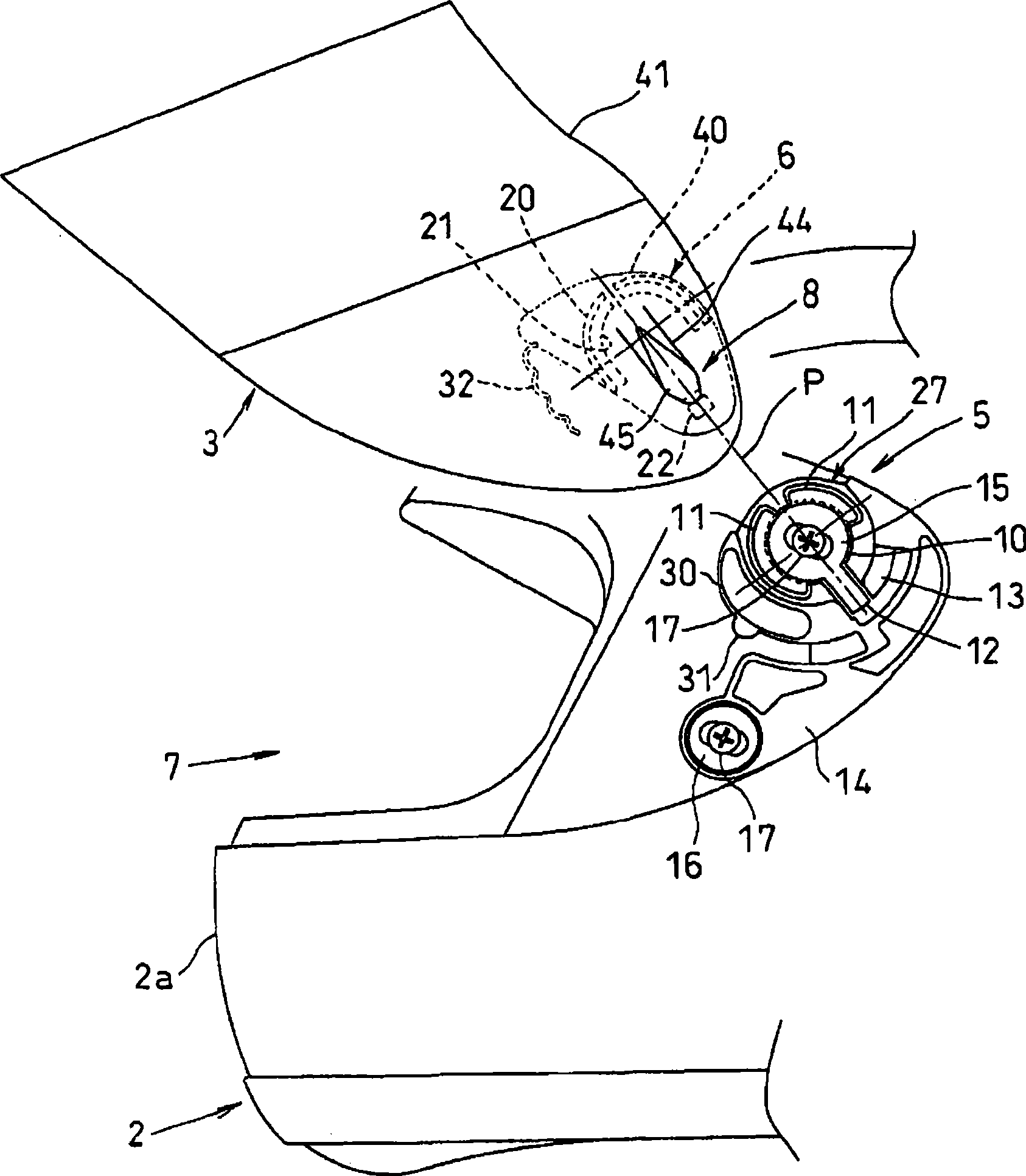

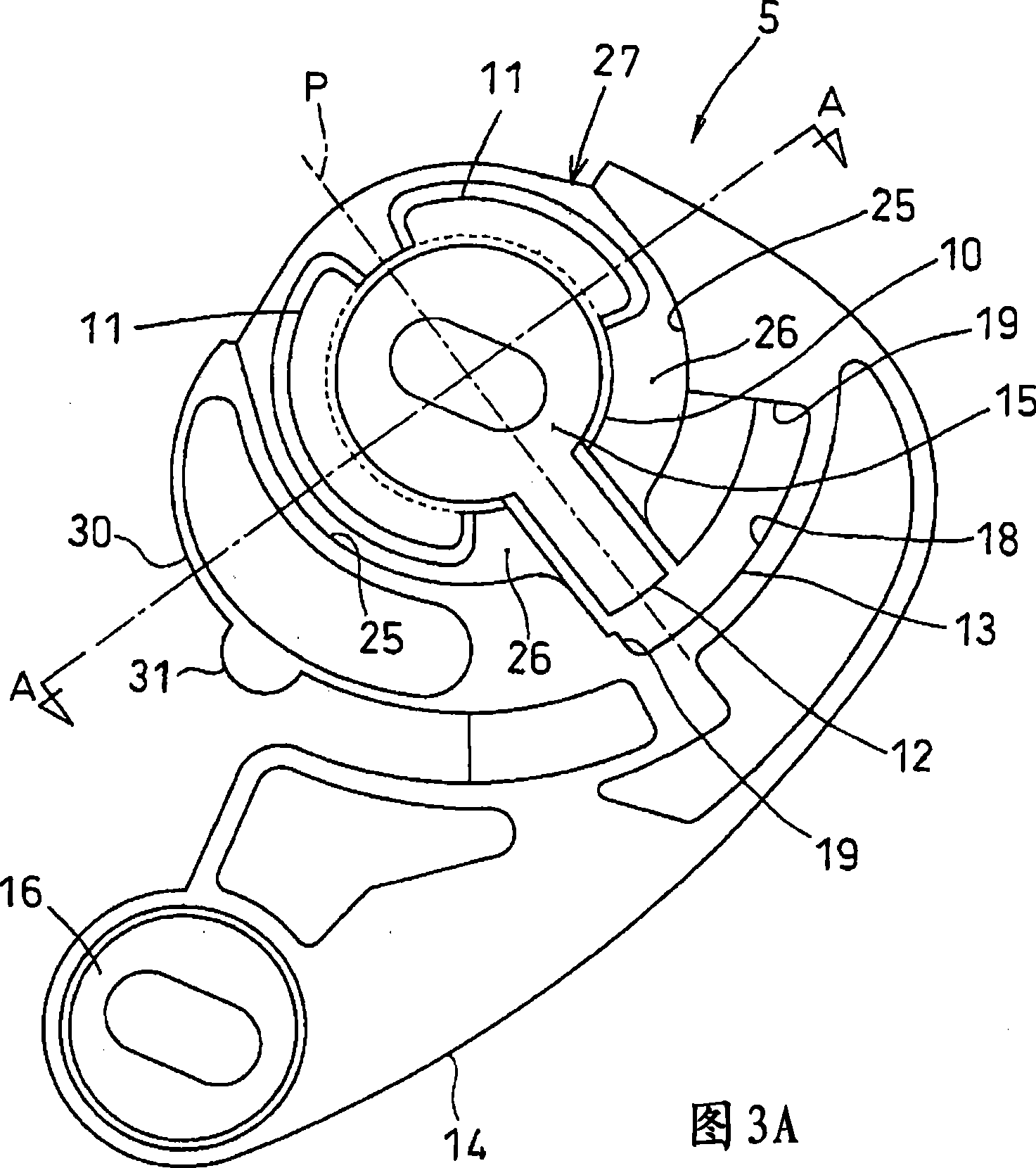

[0040] Figure 1 to Figure 5C One embodiment of the helmet 1 having the shield mounting structure of the present invention is shown. Figure 1 and figure 2 As shown, the helmet 1 has a helmet body 2 and a shield 3 covering the front of the helmet body 2 . The cover 3 is formed of, for example, carbon-containing transparent or colored transparent resin such as polycarbonate, or transparent resin treated with transflective or dimming reflective treatment.

[0041] The left and right sides of the helmet body 2 are provided with rotating support parts 5, and the left and right ends of the shield 3 are provided with rotating parts 6 that are kept in a freely rotatable state and engaged with the left and right rotating support parts 5. In the engaged state of the part 5 and the rotating part 6, the shield 3 can be popped up relative to the helmet body 2 to open the helmet front, or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com