Cover plate disassembly and repair structure for vehicles

A technology for repairing cover and plate structure, which is applied to the superstructure, superstructure sub-assembly, vehicle parts, etc. It can solve the problems that it takes about 10 minutes, the aluminum profile is deformed and rotted, and cannot be opened quickly, so as to achieve quick and labor-saving assembly and disassembly , high product strength and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

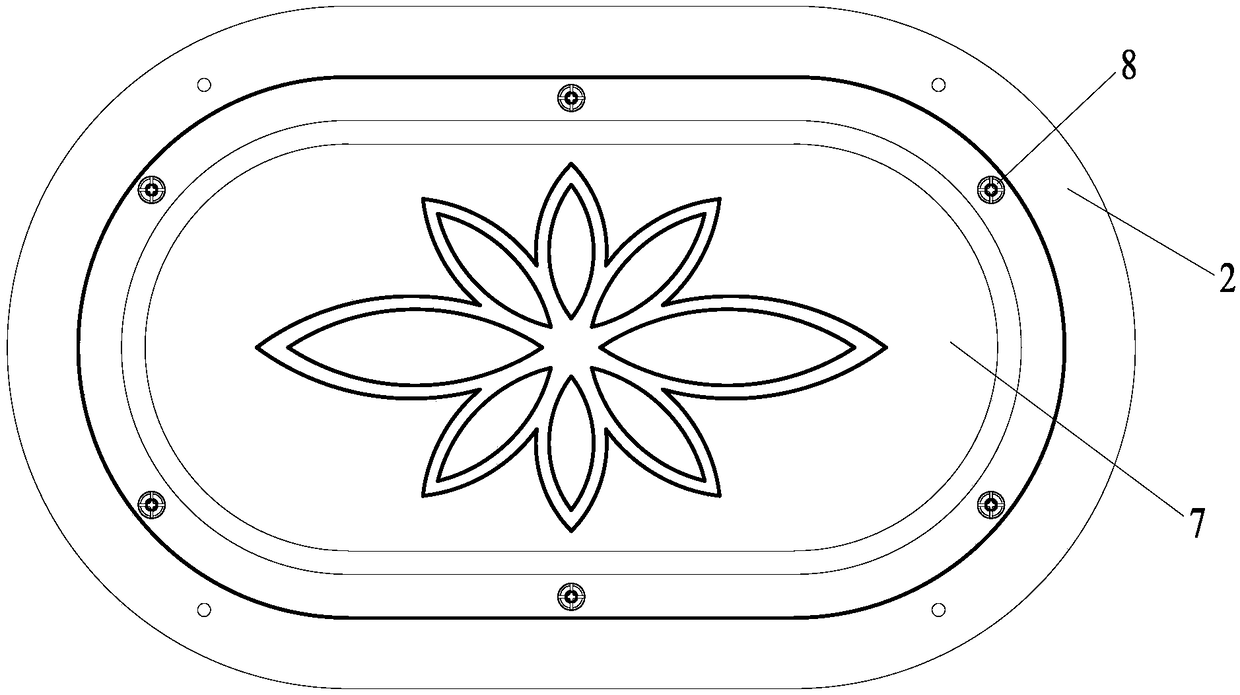

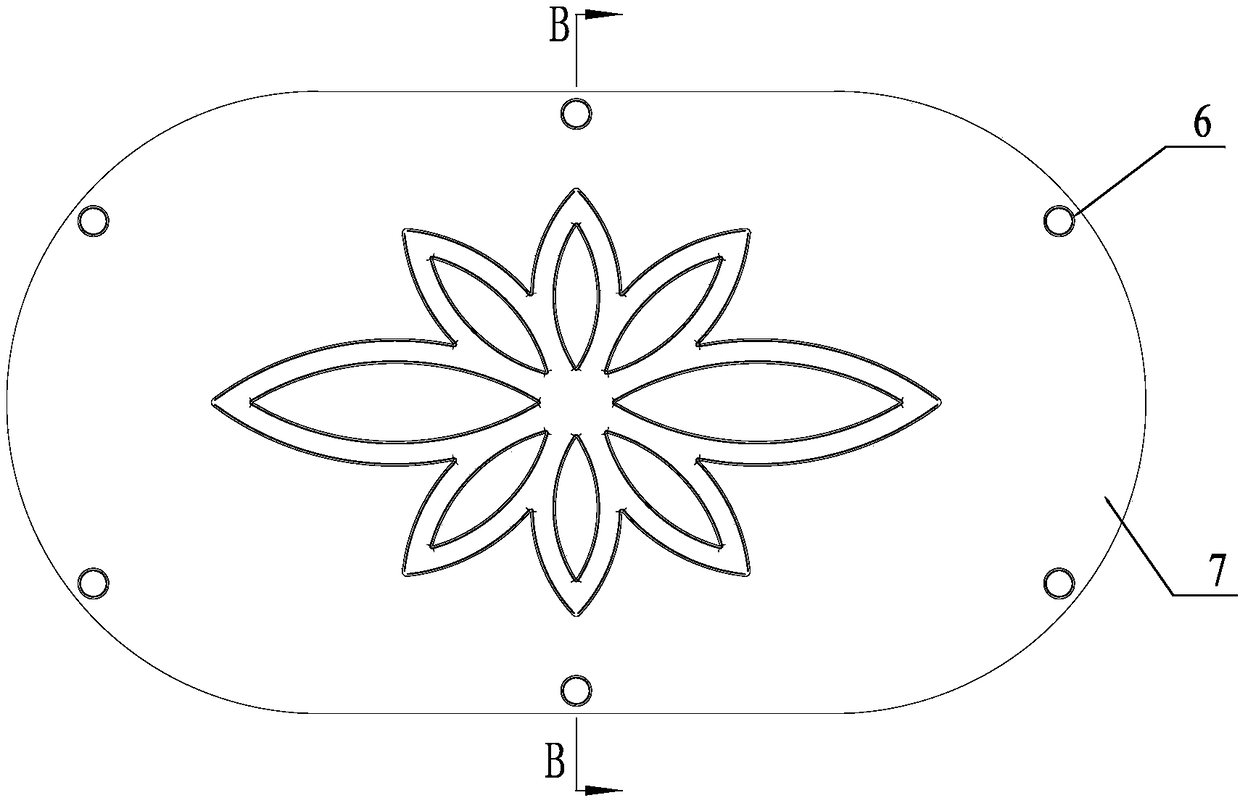

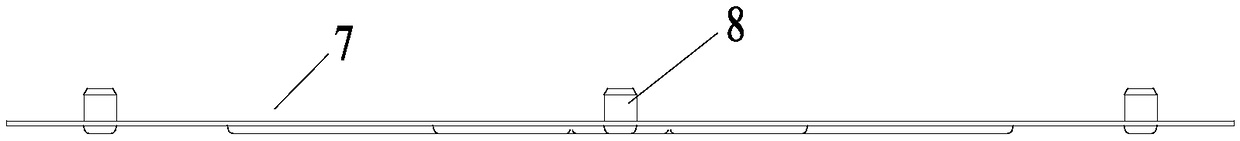

[0027] Figure 1~10 Including opening slot 1, fixed frame 2, installation hole 3, connection hole 4, connection bolt 5, positioning hole 6, cover plate 7, elastic member 7-1, cross groove 7-2, connection buckle 8, embedded Groove 9, sinking platform 10 etc.

[0028] Such as Figure 1~10 As shown, the present invention is a vehicle disassembly maintenance cover plate structure, including an integrally formed fixed frame 2, the fixed frame 2 is provided with a concave fitting groove 9, and the fitting groove 9 is provided with a number of connection holes 4. The cover plate 7 is provided with an elastic connection buckle 8 corresponding to the connection hole 4 one by one, and the connection buckle 8 cooperates with the connection hole 4 to realize the fast connection between the fixed frame 2 and the cover plate 7; The opening notch 1 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com