Clutch release bearing

A separation lever and clutch technology, applied in the direction of clutches, mechanical drive clutches, mechanical equipment, etc., to achieve the effect of promoting wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

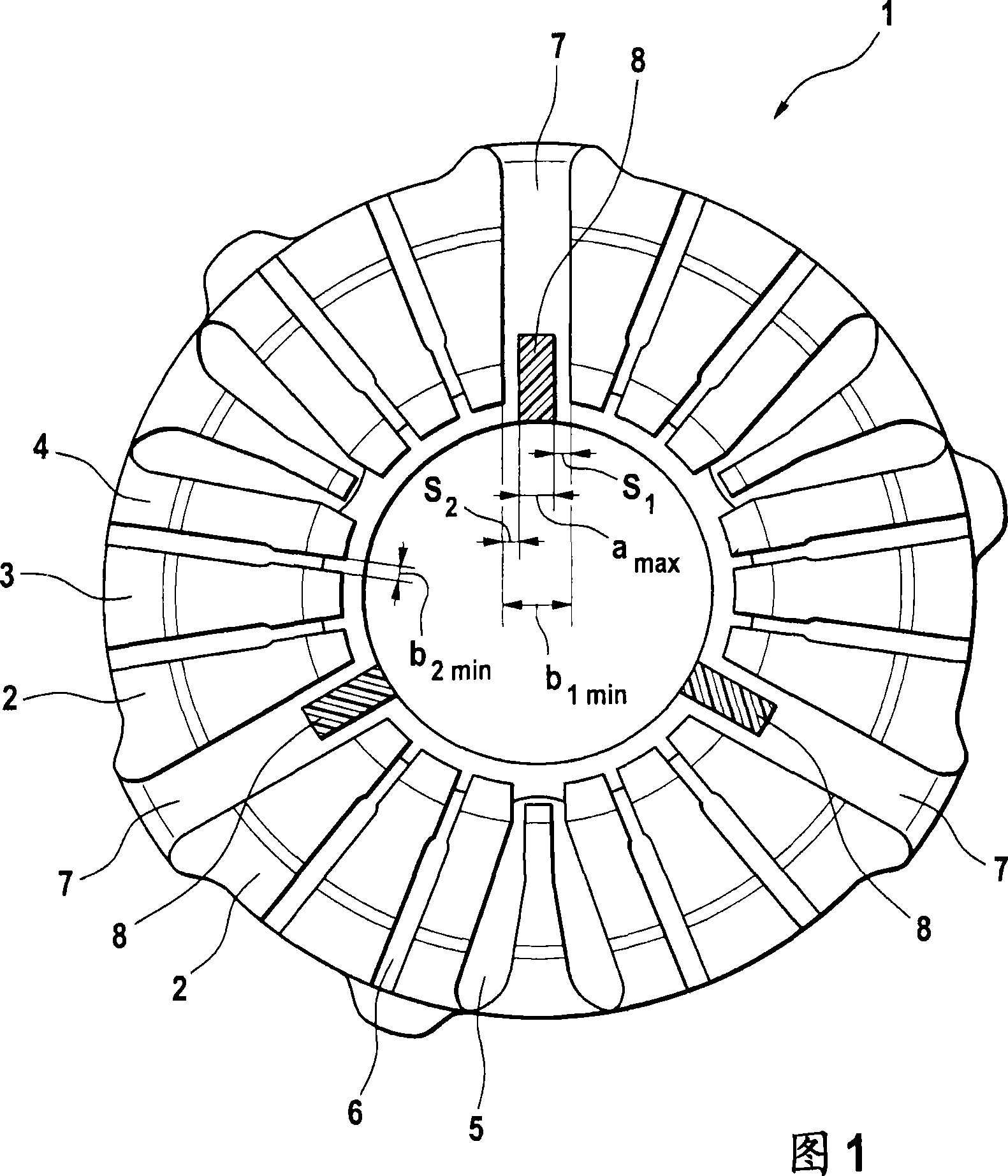

[0032] FIG. 1 shows a diaphragm spring 1 with spring tongues 2 , 3 and 4 . The spring tongues 2 , 3 , 4 are arranged adjacent to one another on the circumference. Two immediately adjacent spring tongues 2 , 3 or 4 are separated from each other on the circumference by a gap 5 , 6 or 7 in each case. The maximum width b of the tangential orientation of the slot 7 1min than the width of the slot 5 or 6 b 2min width.

[0033] A respective rib 8 engages in a respective slot 7 in a form-locking manner. Each individual rib 8 has a maximum width amax in the tangential direction at the point of contact with the rib 8 and is larger than the maximum width b of the slots 5 and 6 2min wide so that the rib 8 cannot be inserted into the slot 5 or 6. The slot 7 has a minimum width at the narrowest point of the slot 7 at the point of contact with the diaphragm spring 1 (that is to say where the rib 8 is embedded), however the minimum width b 1min than the maximum width a of rib 8 max wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com