Anti-dazzling film

An anti-glare film and anti-glare technology, applied in optics, optical components, instruments, etc., can solve the problems of difficult to achieve stable preparation of anti-glare film, large size change of phase separation structure, difficult to control phase separation, etc., and achieve simple performance , High anti-glare, high contrast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0128] [Preparation method of anti-glare film]

[0129] The anti-glare film of the present invention is prepared by the following steps: the wet coating film is inclined relative to the horizontal plane, and at the same time, the wet coating film is dried, and the wet coating film (undried) is subjected to honeycomb rotational convection in the above steps, wherein, The wet coating is formed from a solution comprising at least one polymer, at least one curable resin precursor and a solvent. More specifically, it is generally carried out by applying the solution on a substrate and tilting the resulting wet coating film while evaporating the solvent from the coating film. A more preferable preparation method may be that a solution containing a plurality of polymers capable of phase separation, at least one curable resin precursor, and a solvent having a boiling point above 100° C. is coated on a substrate, and the formed wet coating The film is placed at an inclination with res...

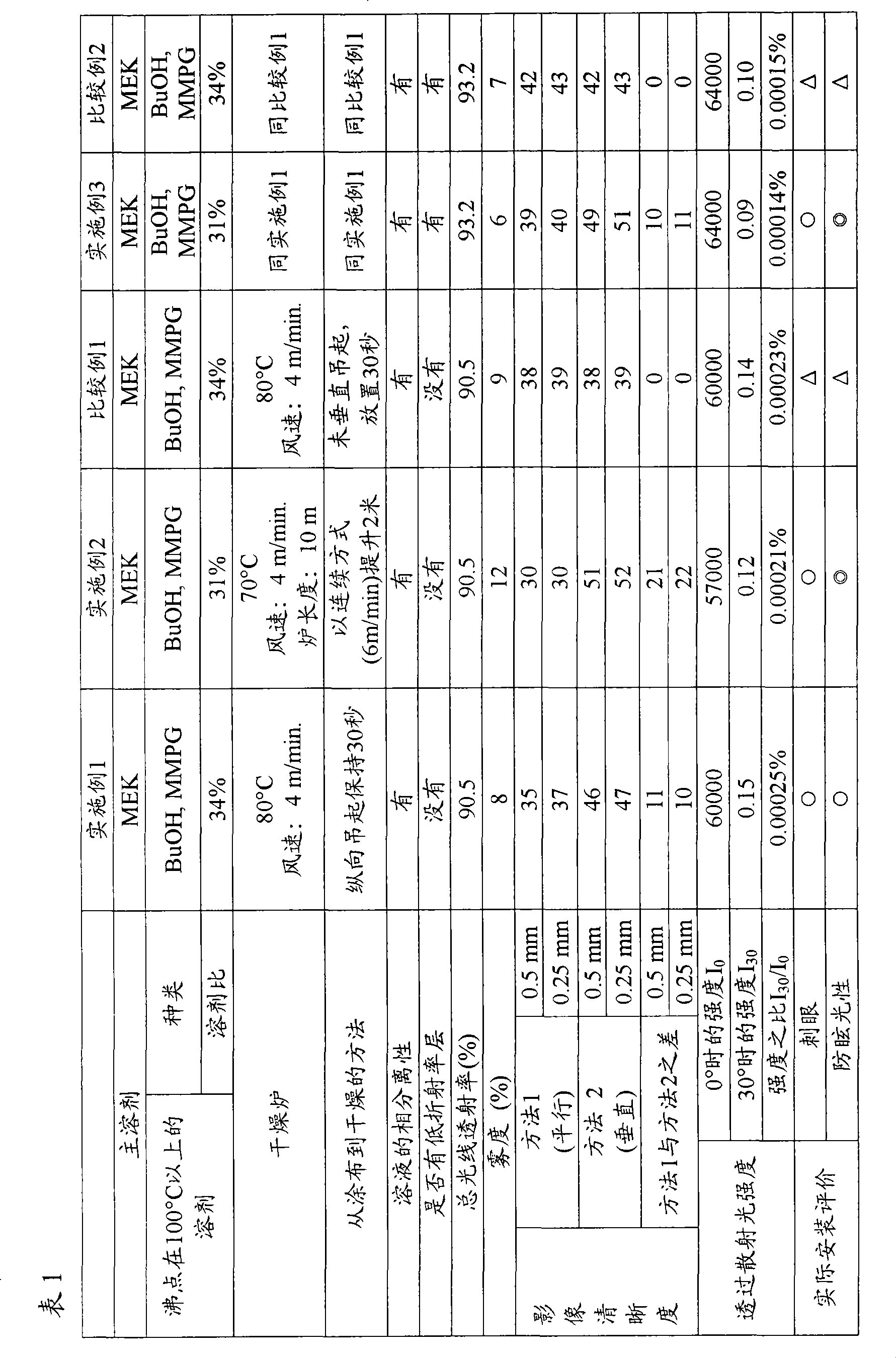

Embodiment 1

[0180] Add acrylic acid 3,4-epoxycyclohexenyl methyl to a part of the carboxyl group of the acrylic resin [(meth)acrylic acid-(meth)acrylate copolymer having a polymerizable unsaturated group on the side chain Ester compound; manufactured by Daicel Chemical Industry Co., Ltd., CYCLOMER-P (ACA) 320M, solid content 44.2% by weight, solvent: 1-methoxy-2-propanol (MMPG) (boiling point 119°C)] 5.88% by weight Parts, cellulose acetate propionate (degree of acetylation=2.5%, degree of propionylation=46%, number average molecular weight obtained in terms of polystyrene: 75,000; manufactured by Eastman Corporation, CAP-482-20) 0.8 parts by weight, multifunctional Acrylic UV curable monomer (DPHA manufactured by daicel-cytec Co., Ltd.) 3.3 parts by weight, multifunctional acrylic UV curable monomer (PETIA manufactured by daicel-cytec Co., Ltd.) 3.3 parts by weight, and photoinitiator (Irgacure 184 manufactured by Ciba Specialty Chemicals Co., Ltd.) 0.5 parts by weight, add and dissolve ...

Embodiment 2

[0182] Add 3,4-epoxycyclohexenyl acrylic acid to a part of the carboxyl group of the acrylic resin [(meth)acrylic acid-(meth)acrylate copolymer having a polymerizable unsaturated group on the side chain. Methyl ester compound; manufactured by Daicel Chemical Industry Co., Ltd., CYCLOMER-P (ACA) 320M, solid content 44.2% by weight, solvent: 1-methoxy-2-propanol (MMPG) (boiling point 119° C.)] 5.66 Parts by weight, cellulose acetate propionate (degree of acetylation=2.5%, degree of propionylation=46%, number average molecular weight in terms of polystyrene: 75,000; manufactured by Eastman, CAP-482-20) 0.6 parts by weight, more 2.76 parts by weight of a functional acrylic UV-curable monomer (DPHA produced by daicel-cytec Co., Ltd.), 2.76 parts by weight of a multifunctional acrylic UV-curable monomer (PETIA produced by daicel-cytec Co., Ltd.), and photoinitiator Agent (Irgacure184 manufactured by Ciba Specialty Chemicals Co., Ltd.) 0.4 parts by weight, added to dissolve in the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com