Installation apparatus for mainshaft bearing of wind-driven generator

A technology for wind turbines and main shaft bearings, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of bearing temperature drop, installation failure, long bearing adjustment time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

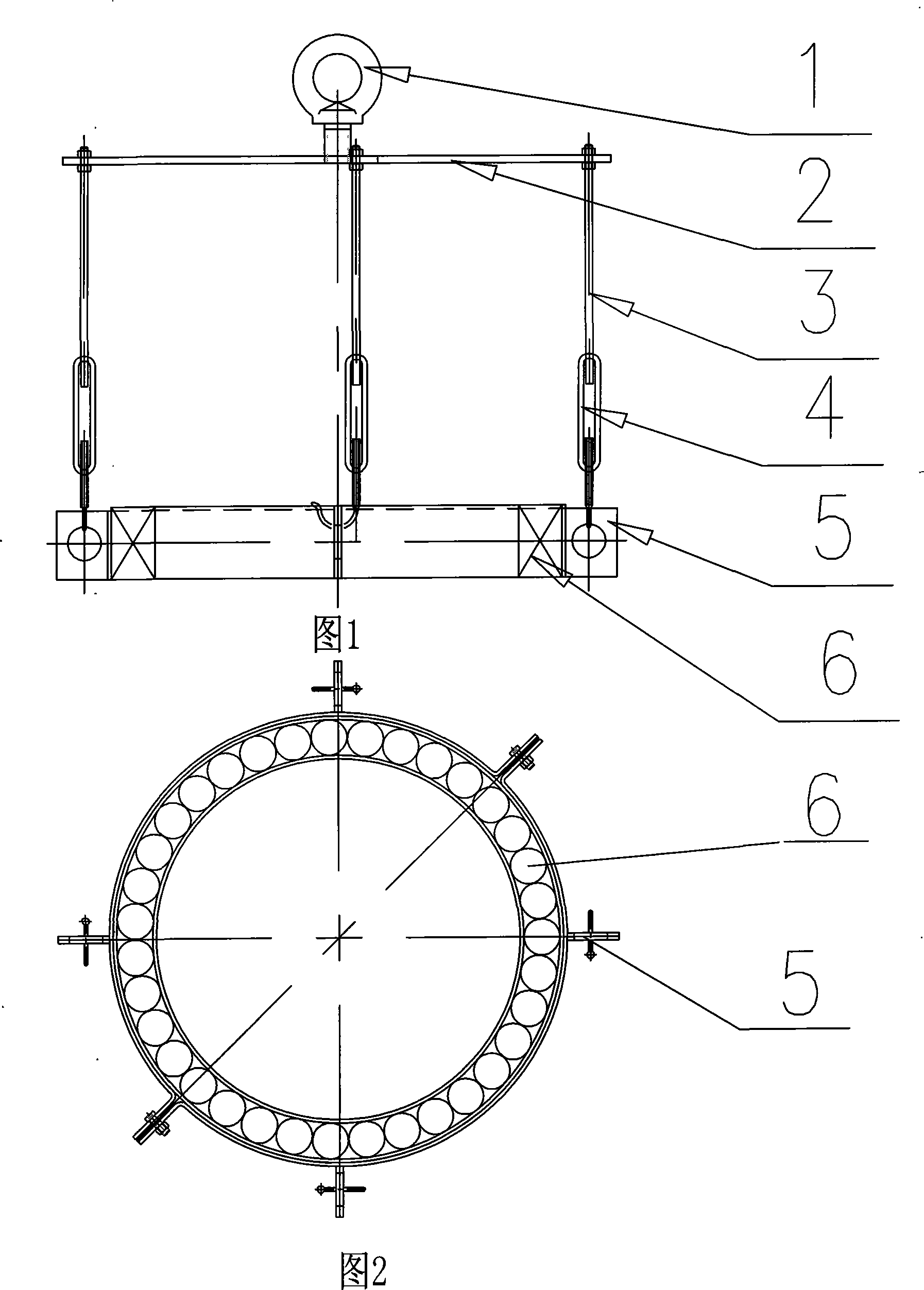

[0012] Below in conjunction with accompanying drawing, the present invention is described in further detail:

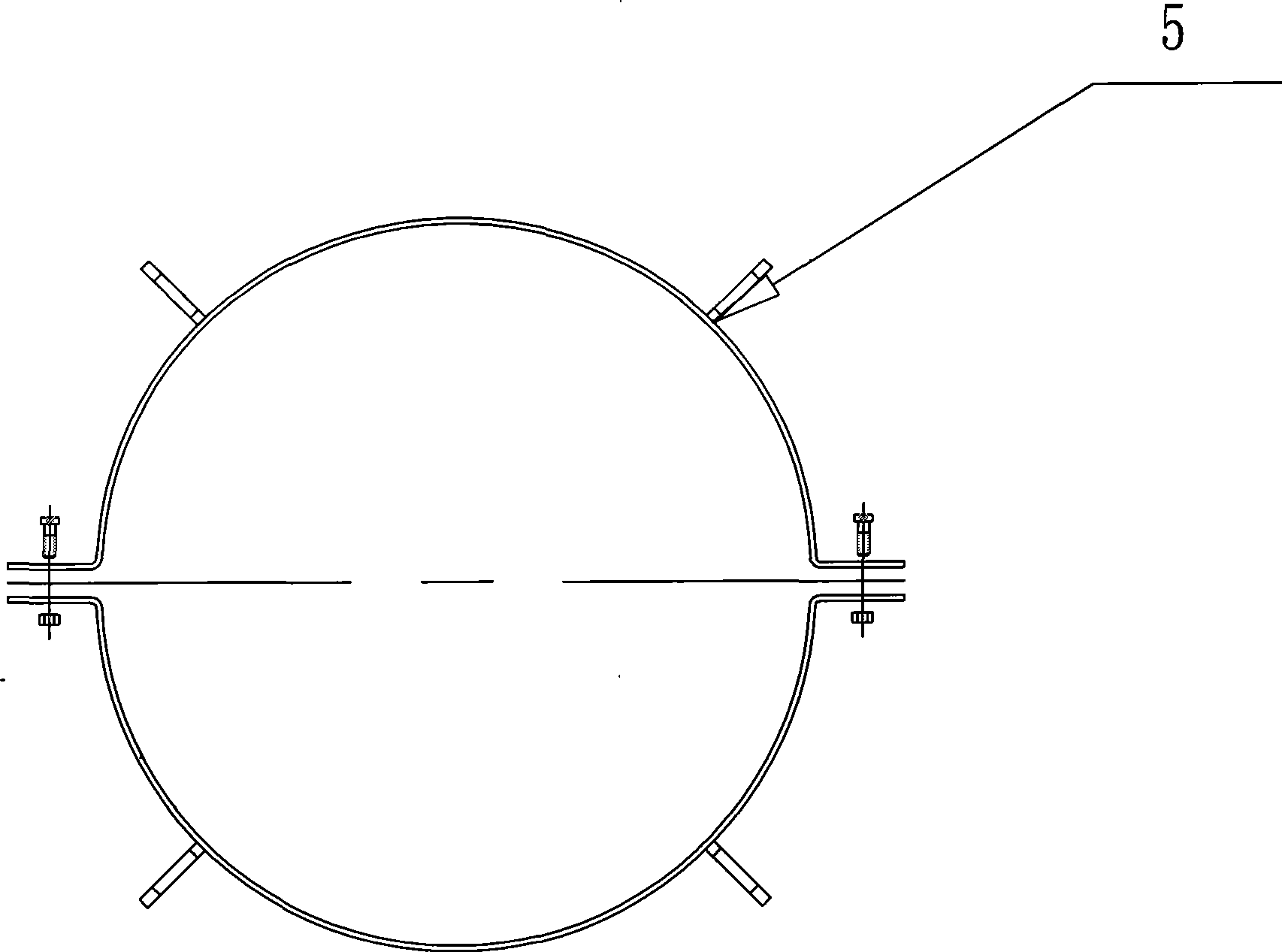

[0013] As shown in Figures 1 and 2, the present embodiment includes a suspension ring 1, a disk 2, a suspension rod 3, a tension hook 4, and a bearing clamping ring 5, and the bearing clamping ring is divided into two semicircular rings ( image 3 ). The bearing clamping ring 5 is an annulus formed by connecting two half annuli with a bolt. Four lifting lugs are evenly distributed on the circumference of the bearing clamping ring. The bore diameter of the bearing clamping ring is slightly smaller than the bearing diameter. Four tensioning hooks 4 pass through the four lifting lugs evenly distributed on the circumference of the bearing clamping ring 5, the upper ends of the four tensioning hooks 4 are connected to the lower ends of the four suspension rods 3, and the upper ends of the four suspension rods 3 are connected to the disc 2 Connection, the suspension ring ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap