Automatic oil recharging device

An automatic oil replenishment and oil level technology is applied to engine components, engine lubrication, mechanical equipment, etc. It can solve the problems of low mechanical strength of the lower oil storage cup, easy to be covered by dirty oil, and easy aging of the cup body. It is easy to judge whether the oil needs to be replaced, the oil consumption of the equipment is convenient, and the effect of visual inspection is easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with the best embodiment.

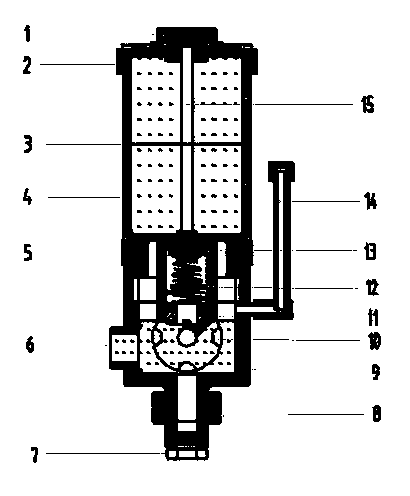

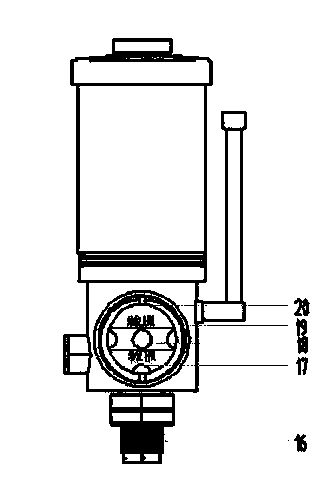

[0016] Such as figure 1 , figure 2 As shown, the automatic oil replenisher of the present invention includes an upper oil storage cup 4 and a lower oil storage cup 9, and the upper oil storage cup 4 and the lower oil storage cup 9 are connected by an oil level adjusting gasket 5 to ensure the oil level; 1. It is convenient for oil filling, and the upper cover 2 is installed on the upper oil storage cup 4 to facilitate cleaning; the spare oil volume scale 3 is marked on the outer wall of the upper oil storage cup 4, which can be used for comparison and statistics of oil consumption; on the upper oil storage cup 4 The guide rod 15 drives the conical plug 13 to compress the conical compression spring 12 on the spring seat 11 under the action of the gravity of the oil, and the conical plug 13 is pushed open, and the oil in the upper oil storage cup 4 is filled to the lower oil storage cup ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com