Manual rocker-type chestnut cross notching machine capable of automatically returning materials

A rocker-type, cross-cut technology, which is applied in the field of manual rocker-type automatic material-returning chestnut cross-cut cutting machine, can solve the problems of high cost, complicated mechanism, and poor quality, and achieves small footprint, simple structure, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiment of the present invention will be further described below, but it is not used to limit the scope of the present invention:

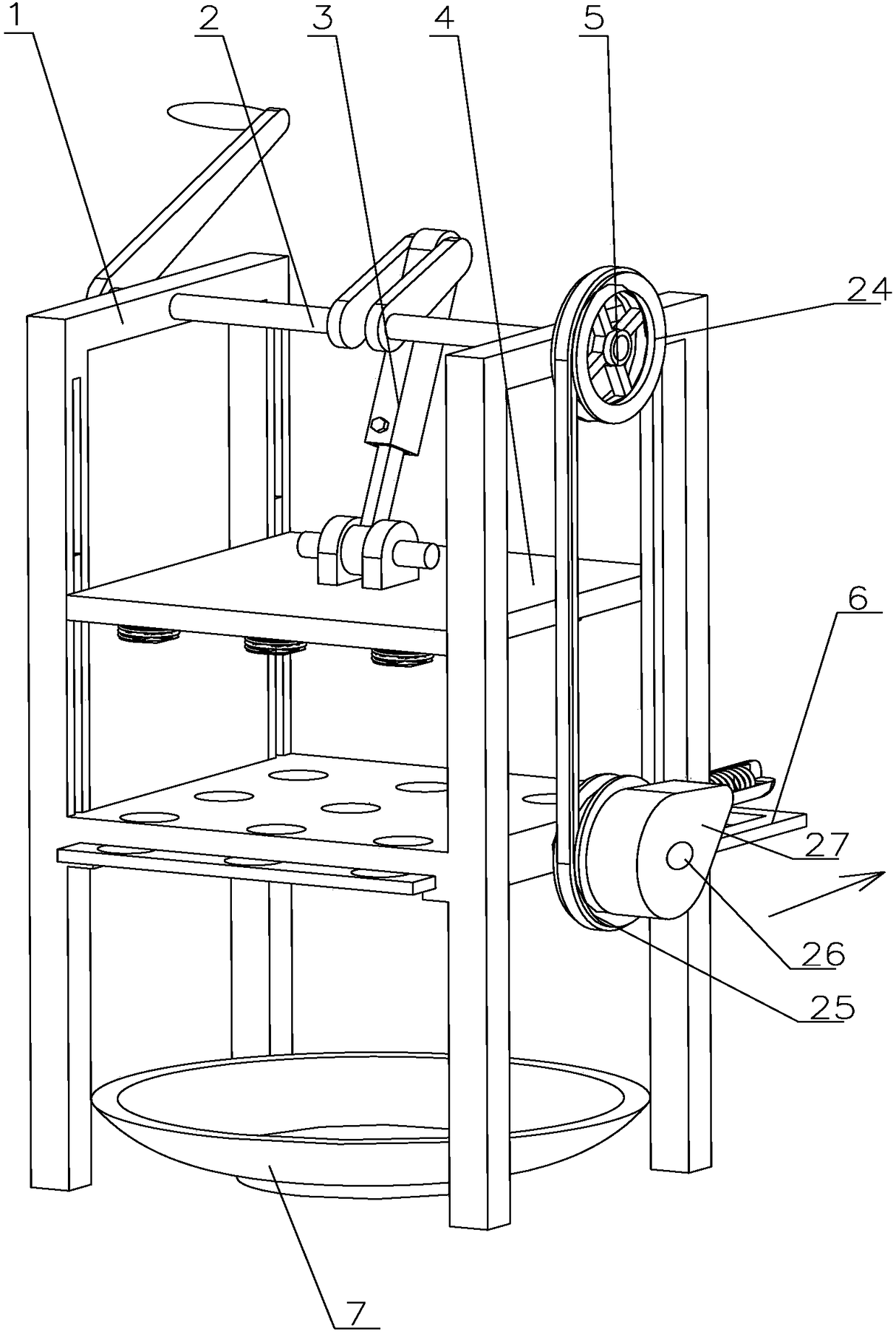

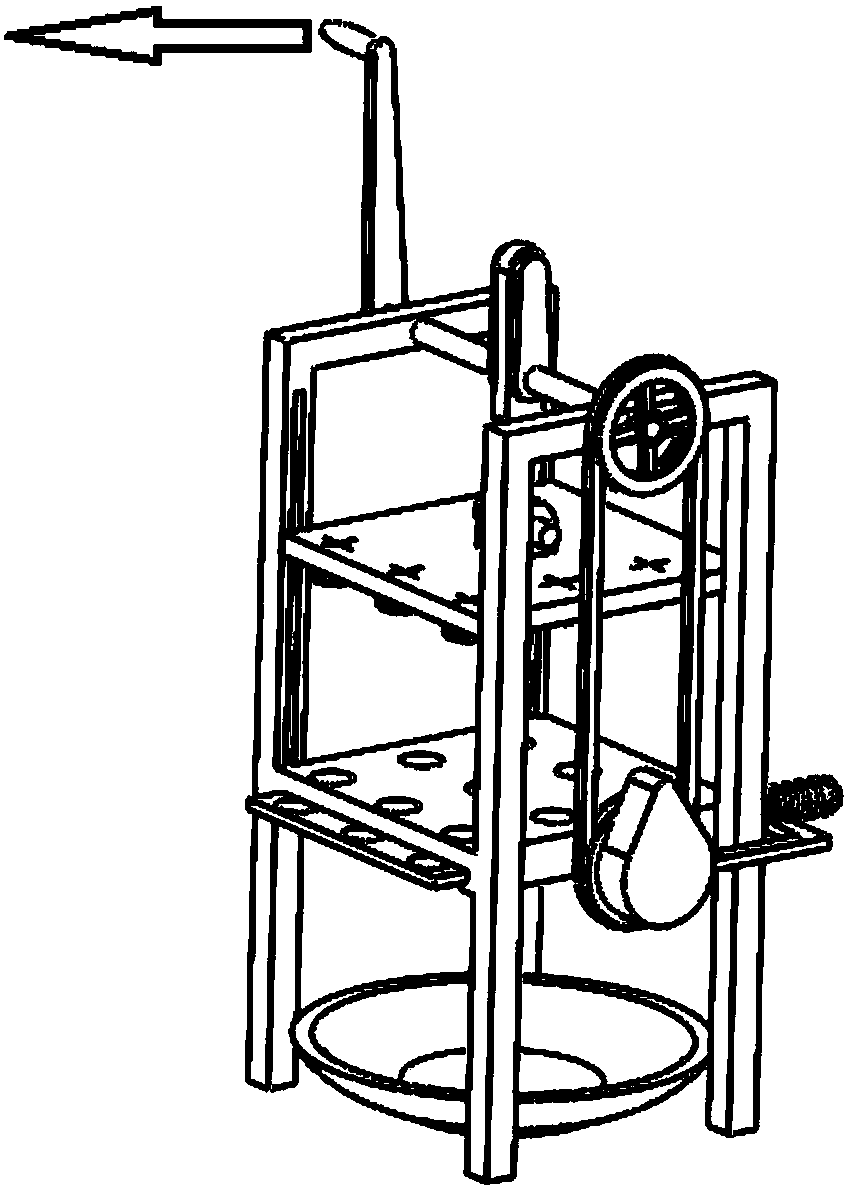

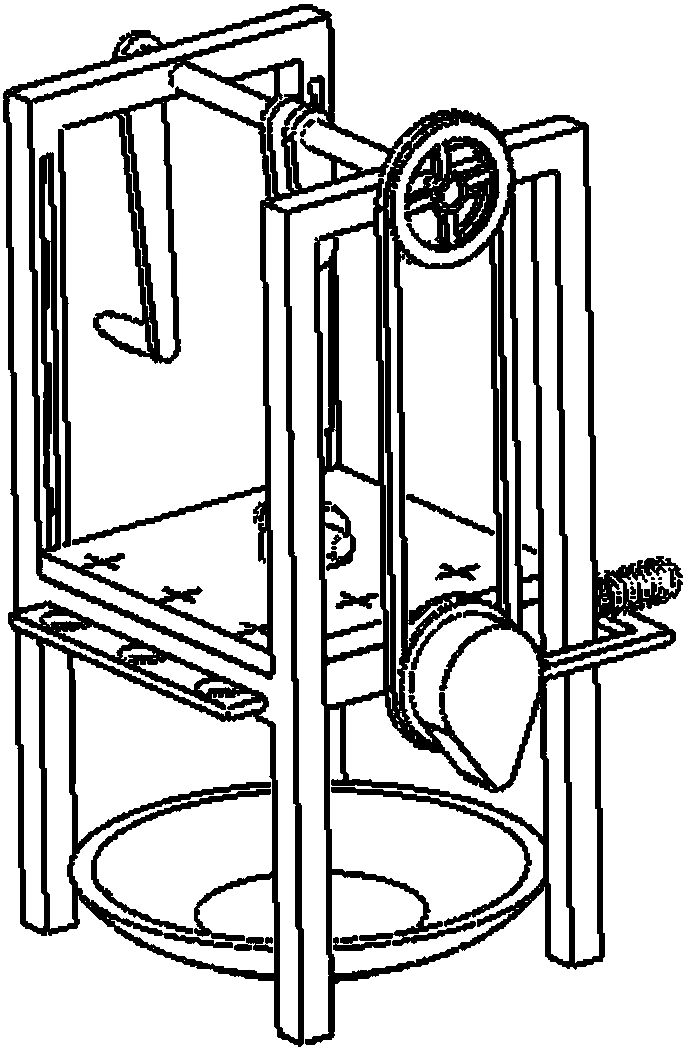

[0033] Such as Figure 1-4 As shown, the manual rocker type automatic material return chestnut crisscross cutting machine includes a frame 1, a rocker mechanism 2, a crank linkage mechanism 3, a cutting device 4, a transmission mechanism 5, a material removal device 6 and a material tray 7.

[0034] Such as Figure 5 As shown, the frame 1 is a rectangular frame structure, made of stainless steel, and welded by the vertical beam 9, the beam 33 and the discharge plate 10. The inside of the vertical beam 9 is provided with a slideway 9 , and the middle part of the beam 33 is provided with a shaft mounting hole 34 . The discharge plate 10 is provided with 3 rows and 3 rows of 9 discharge openings 11 at equal intervals, and the discharge openings 11 are through holes with a diameter of 40 mm. A chute 12 is provided below the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Bottom length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com