Paper stopping component and printer using the same

A technology of printers and components, applied in printing devices, printing, etc., can solve problems such as paper jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

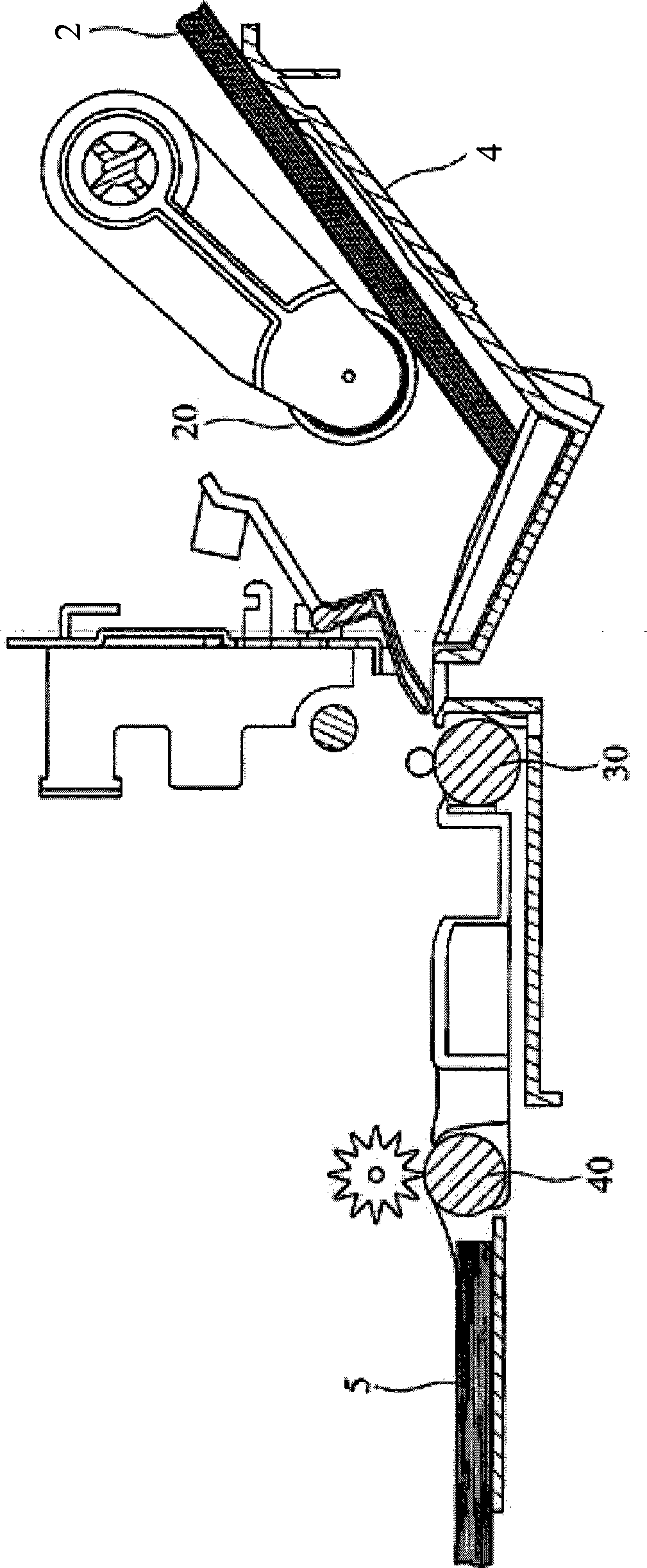

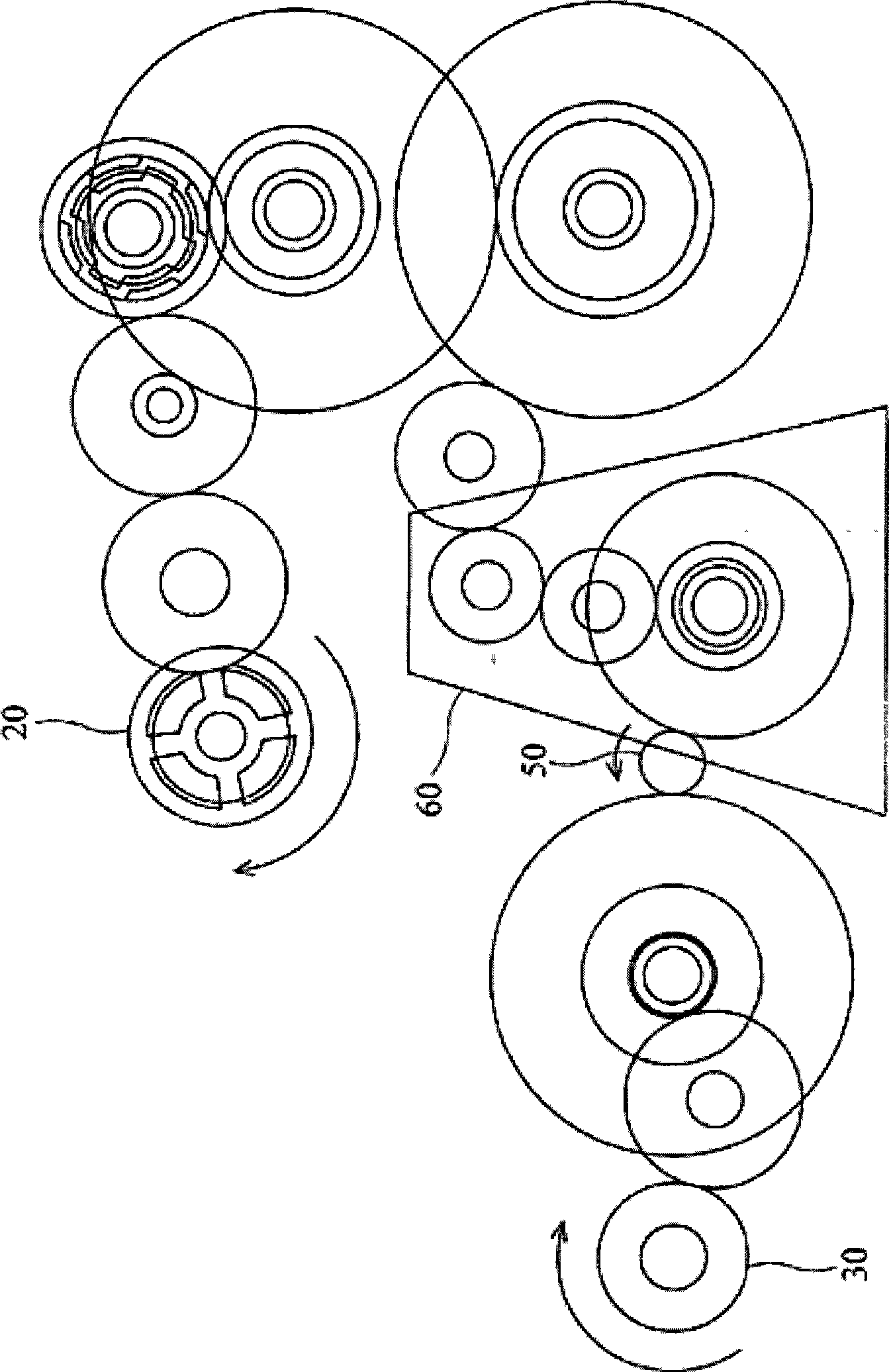

[0019] Please also refer to image 3 and Figure 4 , which are respectively a schematic diagram of a partial structure of a printer according to Embodiment 1 of the present invention and a side view thereof. The printer includes a main body 100 , a feed roller 160 , a paper output roller 120 and a paper blocking member 110 . The paper output roller 120 is set on the main body 100. When printing, the paper 10 is driven into the printing area by the feed roller 160; after the printing is completed, the paper 10 is clamped by the paper clamping member 130 and the paper output roller 120 which are also arranged on the main body 100 to continue to print. The paper tape leaves the paper outlet 5, and falls on the tray 150 after the paper 10 is output.

[0020] The paper blocking member 110 is disposed on the main body 100 by being connected with the rotating shaft 116 , and the paper blocking member 110 can rotate along with the rotating shaft 116 . The paper blocking member 110 ...

Embodiment 2

[0026] Please refer to Image 6 , which is a side view of a partial structure of a printer according to Embodiment 2 of the present invention. The difference from the first embodiment is that the detection device 180 is arranged on the main body 100 relative to the stop portion 114 , and the rest of the same components as the first embodiment continue to use their reference numerals, and their functions will not be repeated. The detection device 180 is, for example, a touch sensor. According to the contact state between the detection device 180 and the stopper 114 , it is detected whether the paper 10 has been detached from the paper output roller 120 . For example, when there is no paper, the detection device 180 and the stopper 114 are in contact with each other. When the paper is input, the stop portion 114 is pressed down, and the detection device 180 is out of contact with the stop portion 114, and the detection device 180 outputs a signal to notify the printer that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com