Method for testing pushing belt and test equipment for implementing the method

A testing method and technology of testing equipment, applied in the testing of mechanical components, testing of machine/structural components, testing of machine gears/transmission mechanism, etc., can solve problems such as cost-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

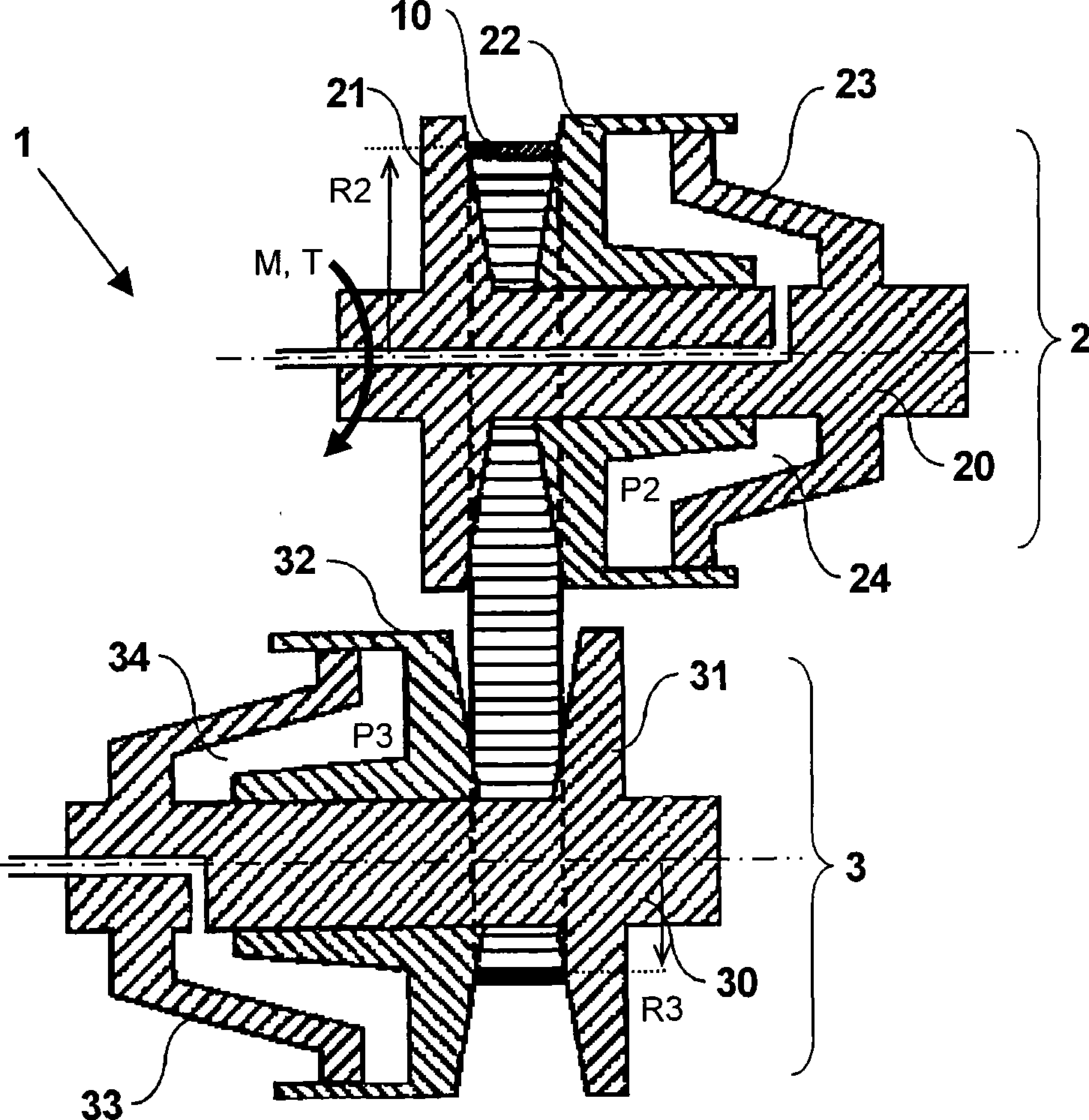

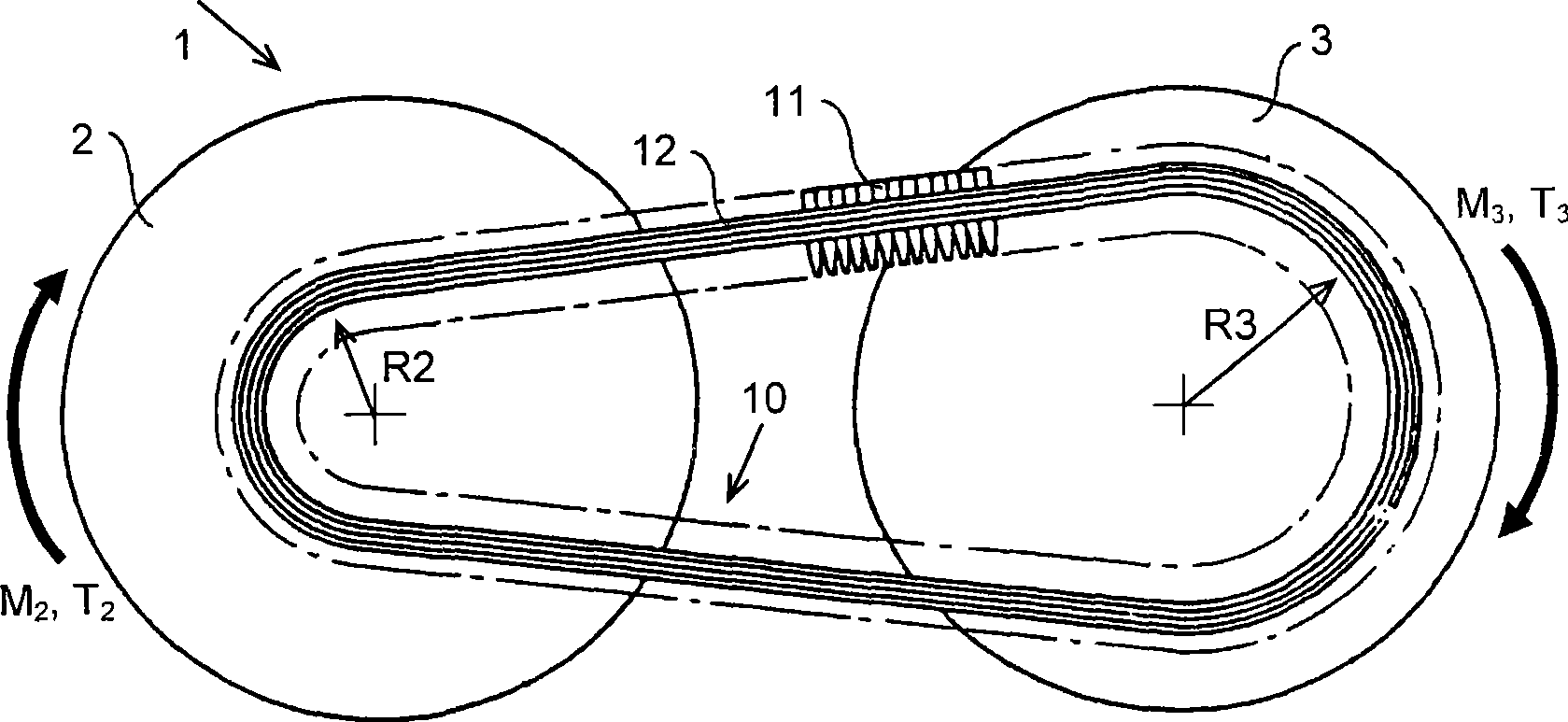

[0027] figure 1There is shown a cross-sectional view of a central portion of a known continuously variable transmission 1 commonly used in the drive train of an automobile between its engine and driven wheels. exist figure 2 A simplified side view of the transmission 1 is provided in .

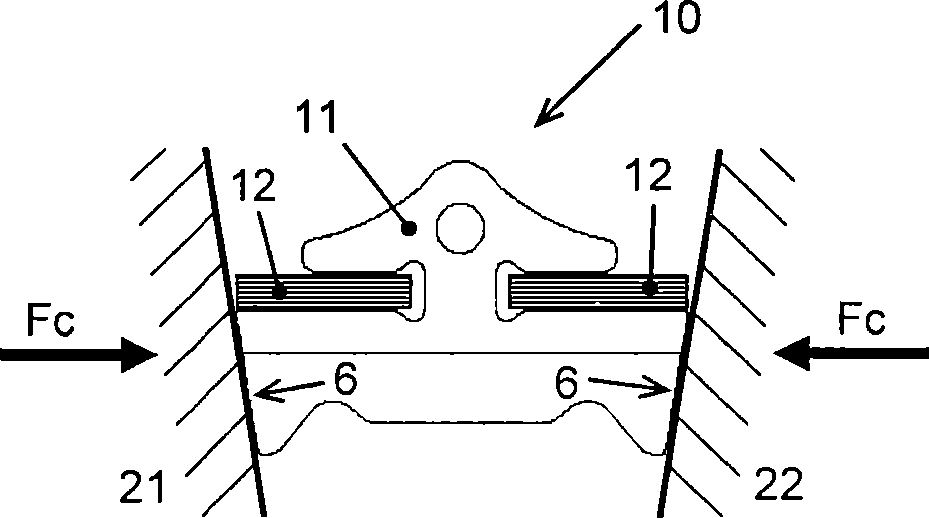

[0028] The known transmission 1 comprises two pulleys 2 and 3, each provided with two pulley sheaves 21, 22 and 31, 32 respectively, between which a drive belt 10 is mounted for running from the drive pulley 2 to the The driven pulley 3 transmits the rotational movement M and the associated torque T. The pulley sheaves 21, 22, 31 and 32 are generally conical in shape and at least one pulley sheave 22, 32 of each pulley 2, 3 is contained in a transmission arranged along its The respective pulley shafts 20, 30 of the respective moving sheaves 22, 32 move axially. In at least the illustrated embodiment, the respective other sheave 21 , 31 of each pulley 2 , 3 is fixed immovably to eg an inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com