Ultra-high-power LED die set light source bracket

A LED module and ultra-high power technology, applied in electrical components, electric solid devices, circuits, etc., can solve the problems of difficult LED lighting, low LED chip power, and difficult chip size, so as to accelerate the pace of popularization , high practicability and economic benefits

Inactive Publication Date: 2009-08-05

DONGGUAN CLED OPTOELECTRONIT TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the constraints of the LED chip manufacturing process, it is difficult to increase the chip size, so that the power of the LED chip is not large (generally below 5W), so it is difficult for the LED packaged in a single chip to meet the needs of lighting. Demand, specially invented the ultra-high power LED module light source bracket

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

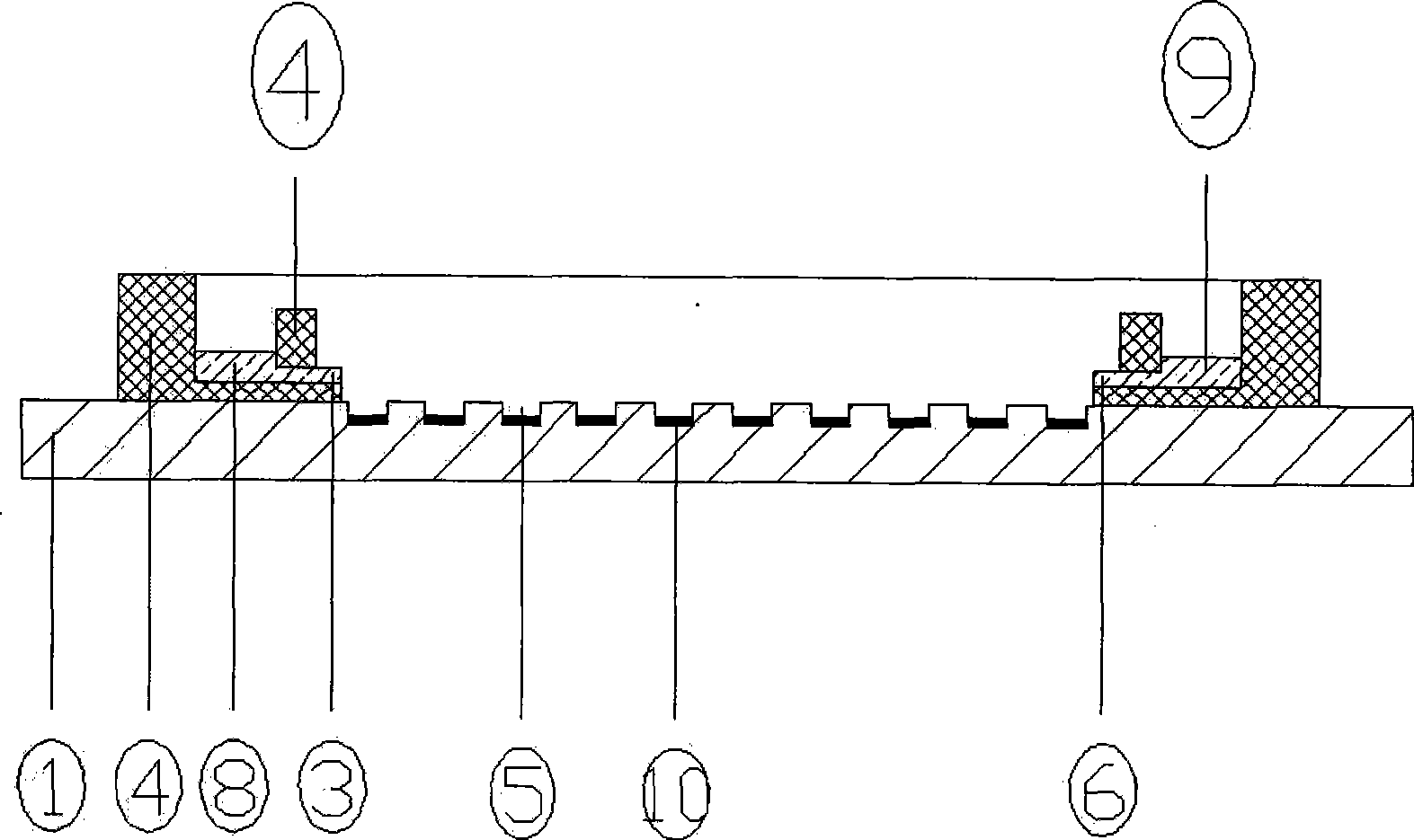

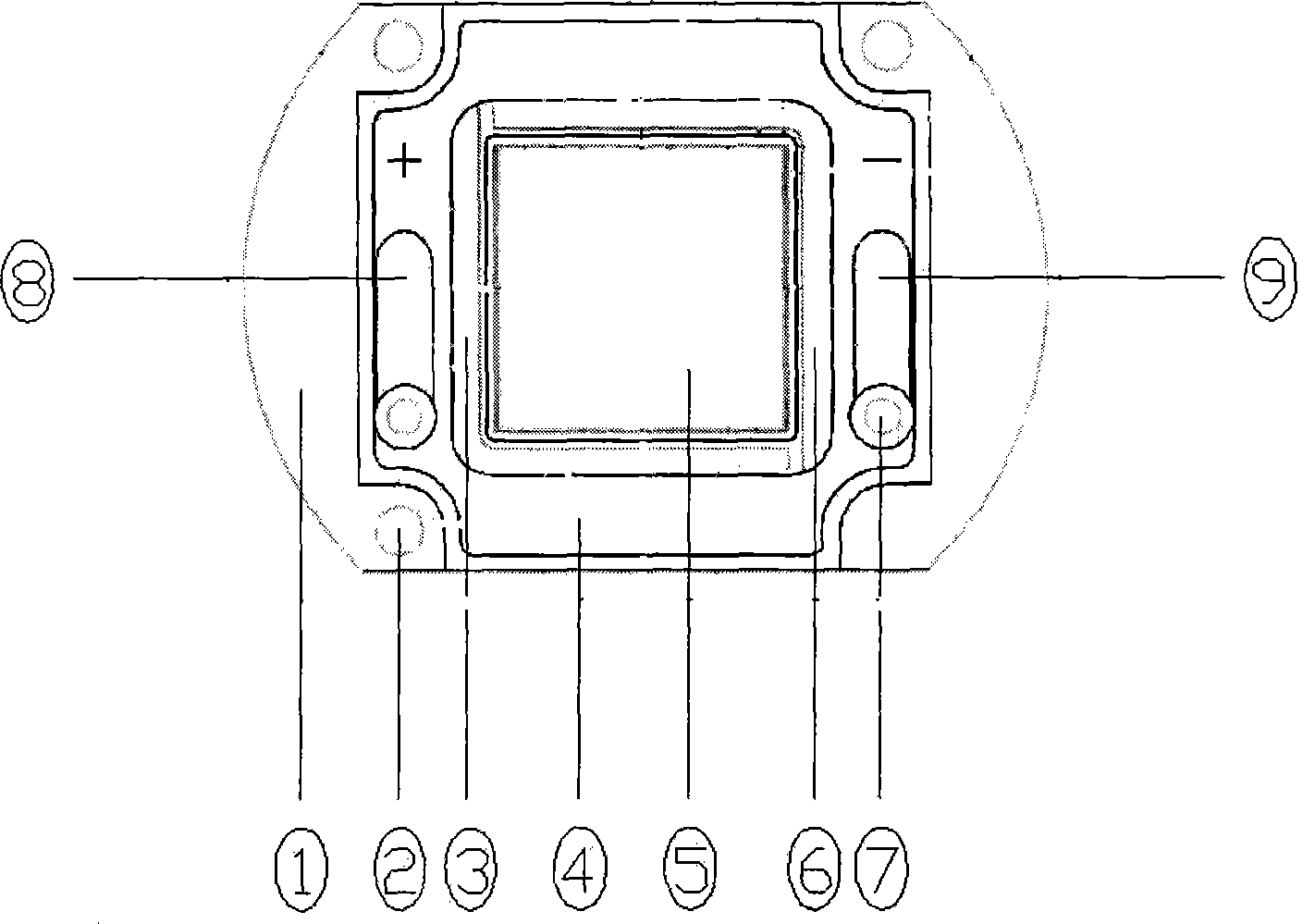

[0015] The ultra-high-power LED module light source support of the present invention can adopt stamping, extruding or die-casting molding processes for its plastic parts, substrates and electrode layers, and the silver plating layer can be realized by using existing technology operations. The connection between the plastic part and the substrate can be fastened together by means of rivets or screws and nuts.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

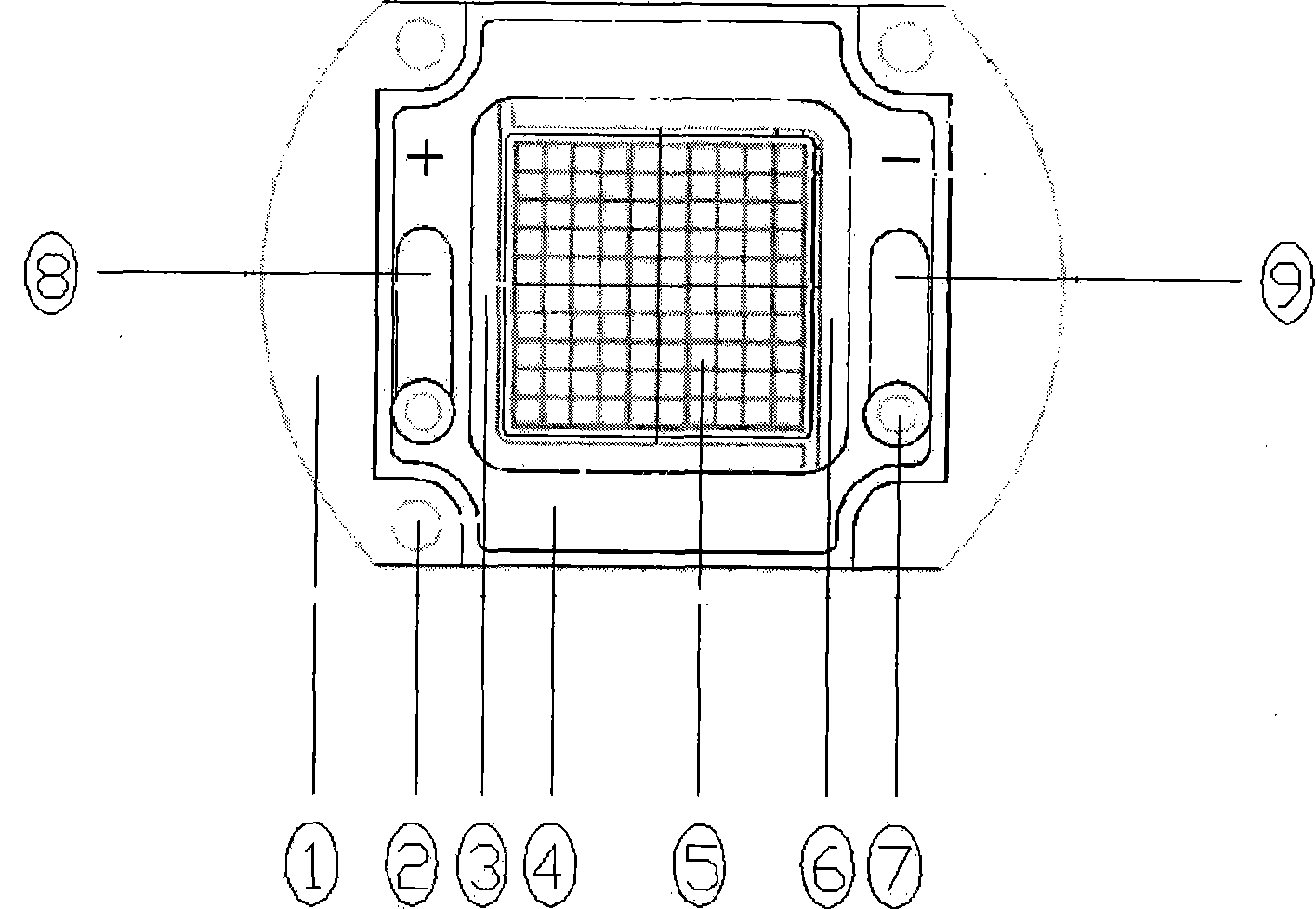

The invention discloses an ultra-high-power LED module light source support, including three parts: a substrate, a plastic piece, and an electrode layer. The LED module light source support is characterized in that the plastic piece comprises the electrode layer and is tightly connected with the substrate. The placement area for the chip in the substrate of the module support has a planar structure or porous structure, and has silver-plated processing or silver wire layer structure within the scope of the area; simultaneously, a plurality of power-typed LED chips can be arranged in the area so as to realize the package of ultra-high-power LED light sources; the LED module light source support is suitable for the package of ultra-high-power LEDs, solves the problem of less package power for a single LED as the self-power of the LED chip is difficult to become large, accelerates the step for generalizing the solid-state lighting, and has high practicability and economic benefits.

Description

technical field [0001] The invention relates to an LED light source bracket, in particular to an ultra-high-power LED module light source bracket for lighting level. Background technique [0002] At present, the world's energy shortage has caused countries to attach great importance to energy-saving technologies. While vigorously developing renewable and clean energy such as solar energy and wind energy, countries are also increasing their efforts in rational and effective use of energy. Reflected in lighting is the continuous innovation and wide application of various new light sources. Among them, light-emitting diodes have attracted more and more attention due to their low energy consumption, high luminous efficiency, long life and high reliability, and have been gradually applied to the lighting field. Due to the constraints of the LED chip manufacturing process, it is difficult to increase the chip size, so that the power of the LED chip is not large (generally below 5...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L25/00H01L25/075H01L23/488H01L23/12

Inventor 陈德华欧发文束红运

Owner DONGGUAN CLED OPTOELECTRONIT TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com